Abstract

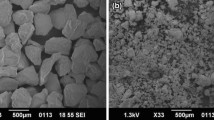

Various mechanisms can affect the permeability of dense unconsolidated sands: Volumetric dilation can lead to permeability increase, whereas strain localization in shear bands may increase or decrease the permeability depending on the state of compaction and on the level of grains breakage inside the band. To investigate these various mechanisms, an experimental study has been performed to explore the effect of different factors such as grain size and grain shape, confining pressure, level of shear, stress path, and formation of one or several shear bands on the permeability of dense sands under triaxial loading. The experimental results show a reduction of permeability during the consolidation phase and during the volumetric contraction phase of shear loading, which can be related to the decrease of porosity. The experimental results also show that, depending on the confining pressure, the permeability remains stable or decreases during the volumetric dilation phase despite the increase of total porosity. This permeability reduction is attributed to the presence of fine particles, which result from grains attrition during pre-localization and grains breakage inside the shear band during the post-localization phase.

Similar content being viewed by others

References

Andò E, Viggiani G, Hall SA, Desrues J (2013) Experimental micro-mechanics of granular media studied by X-ray tomography: recent results and challenges. Géotech Lett 3:142–146. doi:10.1680/geolett.13.00036

Benahmed N, Canou J, Dupla JC (2004) Structure initiale et propriétés de liquéfaction statique d’un sable. C R Méc 332(11):887–894

Crawford BR, Gooch MJ, Webb DW (2004) Textural controls on constitutive behavior in unconsolidated sands: micromechanics and cap plasticity. Proceedings of 6th Int. Conf. North American Rock Mechanics Symposium (NARMS). American Rock Mechanics Association, ARMA/NARMS 04-611

Feda J (2002) Notes on the effect of grain crushing on the granular soil behaviour. Eng Geol 63(1):93–98

Feia S, Ghabezloo S, Bruchon JF, Sulem J, Canou J, Dupla JF (2014) Experimental evaluation of the pore-access size distribution of sands. Geotech Test J 37(4):1–8. doi:10.1520/GTJ20130126

Nguyen VH (2012) Compaction des roches réservoirs peu ou non consolidées: impacts sur les propriétés de transport. Ph.D. thesis, Université de Cergy-Pontoise, France

Olson JE, Yaich E, Holder J (2009) Permeability changes due to shear dilatancy in uncemented sands. Proceedings of US Rock Mechanics/Geomechnics Symp. 28th June–1st July, Asheville, NC, US

Rechenmacher AL, Finno RJ (2004) Digital image correlation to evaluate shear banding in dilative sands. Geotech Test J 27(1):1–10

Scott J, Proskin S, Adhikary D (1994) Volume and permeability changes associated with steam stimulation in an oil sands reservoir. J Can Pet Technol. doi:10.2118/94-07-06

Wong RCK (2000) Shear deformation of locked sand in triaxial compression. Geotech Test J 23(2):158

Acknowledgments

The authors gratefully acknowledge TOTAL for supporting this research. They wish also to thank Irina Andria-Ntoanina, Sara Assandi and Pierre-François Marty for their assistance in the experimental program.

Author information

Authors and Affiliations

Corresponding author

Appendices

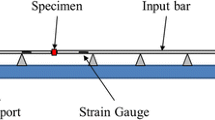

Appendix 1: Correction of the measured permeability taking into account the deformed specimen shape

In the performed constant head permeability tests, the hydraulic conductivity of the specimen is evaluated using Darcy’s law for a one-dimensional flow, k = QL/SΔH, where Q is the water discharge, S is the section of the specimen, ΔH is the hydraulic load, and L is the length of the specimen. During shearing phase, due to deformation and barreling of the specimen, the flow lines are modified and it is necessary to correct the evaluated permeability. This is done by introducing a correction factor obtained from a numerical modeling of the fluid flow in the deformed specimen. Figure 23 shows the geometry of the finite element axisymmetric model of the specimen with length L and a barrel shape defined by the radius R + e of the middle cross section (Fig. 23). The upper and lower sections of the specimen are assumed to keep the initial radius R. The material is assumed to be homogeneous and isotropic, i.e., k x = k y = k, k xy = 0.

Several constant head permeability experiments have been simulated for different values of e, and the permeability k′ is calculated and compared with the real material permeability k. Figure 24 shows that the ratio k′/k can be fitted with a linear trend:

The above correction factor is applied to the measured permeabilities during the triaxial tests. From the measurement of the volume V of the deformed specimen given by the volumeter, the barreling parameter e is calculated from the following relation:

The correction of the measured permeability is of the order of 5 % with a maximum of 10 % at large strains.

Appendix 2: Strain–stress curves of the triaxial tests under constant confining pressure

Figure 25 presents the strain–stress curves of the triaxial tests under constant confining pressure.

Rights and permissions

About this article

Cite this article

Feia, S., Sulem, J., Canou, J. et al. Changes in permeability of sand during triaxial loading: effect of fine particles production. Acta Geotech. 11, 1–19 (2016). https://doi.org/10.1007/s11440-014-0351-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-014-0351-y