Abstract

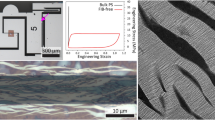

The present paper reports the development of an in situ nanotensilometer that enables highly reliable mechanical tensile testing on individual micro-/nano-scale structures. The device features independent measurement of force and displacement histories in the specimen with nanoNewton force and sub-nanometer displacement resolutions, respectively. Moreover, the device is well suited for in situ testing of free-standing micro/nano-structures within a high resolution scanning electron microscope (SEM), which permits continuous high-resolution imaging of the specimen during straining. The device is comprised of two main parts: (a) a three-plate capacitive transducer that doubles up both as an actuator and a force sensor, and (b) a commercially available nanomanipulator that facilitates transportation and positioning of nanoscale structures with sub-nanometer precision. In order to conduct the mechanical tests the ends of the specimen are attached to the probe tips of the device using ion-beam induced deposition. The general capabilities and features of the nanotensilometer are illustrated by presenting results of nanomechanical tensile tests on electrospun polyaniline microfibers.

Similar content being viewed by others

References

Alivisatos AP, Barbara PF, Castleman AW, Chang J, Dixon DA, Klein ML et al (1998) From molecules to materials: Current trends and future directions. Adv Mater 1016:1297–1336. doi:10.1002/(SICI)1521-4095(199811)10:16<1297::AID-ADMA1297>3.0.CO;2-7.

Samuel BA, Yi B, Rajagopalan R, Foley HC, Haque MA (2006) Mechanical characterization of polymer nanowires using MEMS. Proceedings of the 2006 International Mechanical Engineering Conference and Exposition, ASME, Chicago, IL, Paper # IMECE2006-14859

Xia Y, Yang P, Sun Y, Wu Y, Mayers B, Gates B et al (2003) One-dimensional nanostructures: Synthesis, characterization and applications. Adv Mater 15:353–389. doi:10.1002/adma.200390087.

Lieber CM (2003) Nanoscale science and technology: building a big future from small things. MRS bull 287:486–491.

Whang D, Jin S, Wu Y, Lieber CM (2003) Large-scale hierarchical organization of nanowire arrays for integrated nanosystems. Nano Lett 39:1255–1259. doi:10.1021/nl0345062.

Huang SC, Ball IJ, Kaner RB (1998) Polyaniline Membranes for Pervaporation of Carboxylic Acids and Water. Macromolecules 3116:5456–5464. doi:10.1021/ma971418t.

Wang CH, Dong YQ, Sengothi K, Tan KL, Kang ET (1999) In-vivo tissue response to polyaniline. Synth Met 1021–3:1313–1314. doi:10.1016/S0379-6779(98)01006-6.

Goh JCH, Ouyang HW, Teoh SH, Chan CKC, Lee EH (2003) Tissue-engineering approach to the repair and regeneration of tendons and ligaments. Tissue Eng 9:S31–S44. doi:10.1089/10763270360696969.

Li WJ, Laurencin CT, Caterson EJ, Tuan RS, Ko FK (2002) Electrospun nanofibrous structure: a novel scaffold for tissue engineering. J Biomed Materi Res 604:613–621. doi:10.1002/jbm.10167.

McQuade DT, Pullen AE, Swager TM (2000) Conjugated polymer-based chemical sensors. Chem Rev 1007:2537–2574. doi:10.1021/cr9801014.

Cui Y, Wei QQ, Park HK, Lieber CM (2001) Nanowire nanosensors for highly sensitive and selective detection of biological and chemical species. Science 2935533:1289–1292. doi:10.1126/science.1062711.

Leroux F, Koene BE, Nazar LF (1996) Electrochemical lithium intercalation into a polyaniline/V2o5 nanocomposite. J Electrochem Soc 1439:L181–L183. doi:10.1149/1.1837078.

Kim JS, Reneker DH (1999) Mechanical properties of composites using ultrafine electrospun fibers. Polym Compos 201:124–131. doi:10.1002/pc.10340.

Lin Y-M, Dresselhaus MS, Ying JY (2001) Fabrication structure and transport properties of nanowires. Nanostructured Materials ed.), Academic Press, San Diego, CA, pp 167–199

Reneker DH, Chun I (1996) Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 73:216–223. doi:10.1088/0957-4484/7/3/009.

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol 6315:2223–2253. doi:10.1016/S0266-3538(03)00178-7.

Li D, Xia YN (2004) Electrospinning of nanofibers: reinventing the wheel? Adv Mater 1614:1151–1170. doi:10.1002/adma.200400719.

Smith BW, Luzzi DE (2001) Electron irradiation effects in single wall carbon nanotubes. J Appl Physi 907:3509–3515. doi:10.1063/1.1383020.

Yu MF, Dyer MJ, Skidmore GD, Rohrs HW, Lu XK, Ausman KD et al (1999) Three-dimensional manipulation of carbon nanotubes under a scanning electron microscope. Nanotechnology 103:244–252. doi:10.1088/0957-4484/10/3/304.

Williams PA, Papadakis SJ, Falvo MR, Patel AM, Sinclair M, Seeger A et al (2002) Controlled placement of an individual carbon nanotube onto a microelectromechanical structure. Appl Phys Lett 8014:2574–2576. doi:10.1063/1.1467701.

Lim SC, Kim KS, Lee IB, Jeong SY, Cho S, Yoo JE et al (2005) Nanomanipulator-assisted fabrication and characterization of carbon nanotubes inside scanning electron microscope. Micron (Oxford, England) 365:471–476. doi:10.1016/j.micron.2005.03.005.

Kim KS, Lim SC, Lee IB, An KH, Bae DJ, Choi S et al (2003) In situ manipulation and characterizations using nanomanipulators inside a field emission-scanning electron microscope. Rev Sci Instrum 749:4021–4025. doi:10.1063/1.1597955.

Eppell SJ, Smith BN, Kahn H, Ballarini R (2006) Nano measurements with micro-devices: mechanical properties of hydrated collagen fibrils. Journal of the Royal Society 36:117–121.

Tan EPS, Goh CN, Sow CH, Lim CT (2005) Tensile test of a single nanofiber using an atomic force microscope tip. Appl Phys Lett 867:073115. doi:10.1063/1.1862337.

Zussman E, Chen X, Ding W, Calabri L, Dikin DA, Quintana JP et al (2005) Mechanical and structural characterization of electrospun PAN-derived carbon nanofibers. Carbon 4310:2175–2185. doi:10.1016/j.carbon.2005.03.031.

Ni H, Li XD, Gao HS (2006) Elastic modulus of amorphous SiO2 nanowires. Appl Phys Lett 884:043108. doi:10.1063/1.2165275.

Walters DA, Ericson LM, Casavant MJ, Liu J, Colbert DT, Smith KA et al (1999) Elastic strain of freely suspended single-wall carbon nanotube ropes. Appl Phys Lett 7425:3803–3805. doi:10.1063/1.124185.

Tan EPS, Lim CT (2004) Novel approach to tensile testing of micro- and nanoscale fibers. Rev Sci Instrum 758:2581–2585. doi:10.1063/1.1775309.

Shin MK, Kim SI, Kim SJ, Kim SK, Lee H, Spinks GM (2006) Size-dependent elastic modulus of single electroactive polymer nanofibers. Appl Phys Lett 8923:231929. doi:10.1063/1.2402941.

Salvetat JP, Kulik AJ, Bonard JM, Briggs GAD, Stockli T, Metenier K et al (1999) Elastic modulus of ordered and disordered multiwalled carbon nanotubes. Adv Mater 112:161–165. doi:10.1002/(SICI)1521-4095(199902)11:2<161::AID-ADMA161>3.0.CO;2-J.

Shanmugham S, Jeong JW, Alkhateeb A, Aston DE (2005) Polymer nanowire elastic moduli measured with digital pulsed force mode AFM. Langmuir 2122:10214–10218. doi:10.1021/la050538o.

Cuenot S, Demoustier-Champagne S, Nysten B (2000) Elastic modulus of polypyrrole nanotubes. Phys Rev Lett 858:1690–1693. doi:10.1103/PhysRevLett.85.1690.

Duvail JL, Retho P, Godon C, Marhic C, Louarn G, Chauvet O et al (2003) Physical properties of conducting polymer nanofibers. Synth Met 1351–3:329–330. doi:10.1016/S0379-6779(02)00626-4.

Desai AV, Haque MA (2006) Mechanical characterization of zinc oxide nanowires, Paper # IMECE2006-14835. Proceedings of the 2006 International Mechanical Engineering Conference and Exposition, ASME

Wong E, Sheehan P, Lieber C (1997) Nanobeam mechanics: elasticity, strength and toughness of nanorods and nanotubes. Science 277:1971–1975. doi:10.1126/science.277.5334.1971.

Tan EPS, Lim CT (2004) Physical properties of a single polymeric nanofiber. Appl Phys Lett 849:1603–1605. doi:10.1063/1.1651643.

Haque MA, Saif MTA (2005) In situ tensile testing of nanoscale freestanding thin films inside a transmission electron microscope. J Mater Res 207:1769–1777. doi:10.1557/JMR.2005.0220.

Dohn S, Kjelstrup-Hansen J, Madsen DN, Molhave K, Boggild P (2005) Multi-walled carbon nanotubes integrated in microcantilevers for application of tensile strain. Ultramicroscopy 1051–4:209–214. doi:10.1016/j.ultramic.2005.06.038.

Chasiotis I, Knauss WG (2002) A new microtensile tester for the study of MEMS materials with the aid of atomic force microscopy. Exp Mech 421:51–57. doi:10.1007/BF02411051.

Zhu Y, Espinosa HD (2005) An electromechanical material testing system for in situ electron microscopy and applications. Proc Natl Acad Sci USA 10241:14503–14508. doi:10.1073/pnas.0506544102.

Yu MF, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS (2000) Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science 2875453:637–640. doi:10.1126/science.287.5453.637.

Ruoff RS, Calabri L, Ding W, Pugno NM (2005) Experimental tests on fracture strength of nanotubes. Rev Adv Mater Sci 102:110–117.

Yu MF, Files BS, Arepalli S, Ruoff RS (2000) Tensile loading of ropes of single wall carbon nanotubes and their mechanical properties. Phys Rev Lett 8424:5552–5555. doi:10.1103/PhysRevLett.84.5552.

Haque MA, Saif MTA (2002) Application of MEMS force sensors for in-situ mechanical characterization of nanoscale thin films in SEM and TEM. Sens Actuators, A, Phys 97–98:239–245. doi:10.1016/S0924-4247(01)00861-5.

Lu SN, Dikin DA, Zhang SL, Fisher FT, Lee J, Ruoff RS (2004) Realization of nanoscale resolution with a micromachined thermally actuated testing stage. Rev Sci Instrum 756:2154–2162. doi:10.1063/1.1710703.

Chasiotis I (2007) Nanoscale measurements in mechanics. Exp Mech 471:5–6. doi:10.1007/s11340-006-0712-z.

Prorok BC, Zhu Y, Espinosa HD, Bazant ZP, Guo Z, Zhao Y et al (2004) Micro- and nanomechanics. Encyclopedia of Nanoscience and Nanotechnology5th edn. American Scientific Publisher, Stevenson Ranch, CA, pp 561–606.

Ruoff RS, Qian D, Liu WK (2003) Mechanical properties of carbon nanotubes: theoretical predictions and experimental measurements. Comptes Rendus Physique 49:993–1008. doi:10.1016/j.crhy.2003.08.001.

Tabib-Azar M, Nassirou M, Wang R, Sharma S, Kamins TI, Islam MS et al (2005) Mechanical properties of self-welded silicon nanobridges. Appl Phys Lett 8711:113102. doi:10.1063/1.2042549.

Li D, McCann JT, Xia YN (2006) Uniaxial alignment of electrospun nanofibers. Polymeric Nanofibers (918th ed.), pp 319–329

Salvetat JP, Bonard JM, Thomson NH, Kulik AJ, Forro L, Benoit W et al (1999) Mechanical properties of carbon nanotubes. Appl Phys, A Mater Sci Process 693:255–260. doi:10.1007/s003390050999.

Ding WQ, Calabri L, Chen XQ, Kohhaas KM, Ruoff RS (2006) Mechanics of crystalline boron nanowires. Compos Sci Technol 669:1112–1124. doi:10.1016/j.compscitech.2005.11.030.

Samuel BA, Desai AV, Haque MA (2006) Design and modeling of a MEMS pico-Newton loading/sensing device. Sens Actuators, A, Phys 1271:155–162. doi:10.1016/j.sna.2005.11.018.

Zhu Y, Corigliano A, Espinosa HD (2006) A thermal actuator for nanoscale in situ microscopy testing: design and characterization. J. Micromechanics Microengineering 162:242–253. doi:10.1088/0960-1317/16/2/008.

Samuel BA, Desai AV, Haque MA (2005) Microscale application of column theory for high resolution force and displacement sensing. Appl Phys Lett 872:021904. doi:10.1063/1.1989440.

Doshi J, Reneker DH (1995) Electrospinning process and applications of electrospun fibers. J Electrost 352–3:151–160. doi:10.1016/0304-3886(95)00041-8.

Jaeger R, Bergshoef MM, Batlle CMI, Schonherr H, Vancso GJ (1998) Electrospinning of ultra-thin polymer fibers. Macromol Symp 127:141–150.

Fong H, Reneker DH (1999) Elastomeric nanofibers of styrene-butadiene-styrene triblock copolymer. J Polym Sci, B, Polym Phys 3724:3488–3493. doi:10.1002/(SICI)1099-0488(19991215)37:24<3488::AID-POLB9>3.0.CO;2-M.

Yarin AL, Koombhongse S, Reneker DH (2001) Bending instability in electrospinning of nanofibers. J Appl Physi 895:3018–3026. doi:10.1063/1.1333035.

Zussman E, Theron A, Yarin AL (2003) Formation of nanofiber crossbars in electrospinning. Appl Phys Lett 826:973–975. doi:10.1063/1.1544060.

Theron A, Zussman E, Yarin AL (2001) Electrostatic field-assisted alignment of electrospun nanofibres. Nanotechnology 123:384–390. doi:10.1088/0957-4484/12/3/329.

Deitzel JM, Kleinmeyer JD, Hirvonen JK, Tan NCB (2001) Controlled deposition of electrospun poly(ethylene oxide) fibers. Polymer 4219:8163–8170. doi:10.1016/S0032-3861(01)00336-6.

Fong H, Liu WD, Wang CS, Vaia RA (2002) Generation of electrospun fibers of nylon 6 and nylon 6-montmorillonite nanocomposite. Polymer 433:775–780. doi:10.1016/S0032-3861(01)00665-6.

Dersch R, Liu TQ, Schaper AK, Greiner A, Wendorff JH (2003) Electrospun nanofibers: Internal structure and intrinsic orientation. J Polym Sci, A, Polym Chem 414:545–553. doi:10.1002/pola.10609.

Li D, Wang YL, Xia YN (2003) Electrospinning of polymeric and ceramic nanofibers as uniaxially aligned arrays. Nano Lett 38:1167–1171. doi:10.1021/nl0344256.

Ding W, Dikin DA, Chen X, Piner RD, Ruoff RS, Zussman E et al (2005) Mechanics of hydrogenated amorphous carbon deposits from electron-beam-induced deposition of a paraffin precursor. J Appl Physi 981:014905. doi:10.1063/1.1940138.

Li CY, Ruoff RS, Chou TW (2005) Modeling of carbon nanotube clamping in tensile tests. Compos Sci Technol 6515–16:2407–2415. doi:10.1016/j.compscitech.2005.06.019.

Beaulieu D, Ding Y, Wang ZL, Lackey WJ (2005) Influence of process variables on electron beam chemical vapor deposition of platinum. Journal of Vacuum Science & Technology B Microelectronics and Nanometer Structures 235:2151–2159. doi:10.1116/1.2050672.

Rykaczewski K, White WB, Fedorov AG (2007) Analysis of electron beam induced deposition (EBID) of residual hydrocarbons in electron microscopy. J Appl Physi 1015:054307. doi:10.1063/1.2437065.

Singh U, Prakash V, Abramson AR, Chen W, Qu L, Dai L (2006) Mechanical characterization device for in situ measurement of nanomechanical properties of micro/nanostructures. Appl Phys Lett 89(7):i.d. 073103

Li XD, Wang XN, Chang WC, Chao YJ, Chang M (2005) Effect of tensile offset angles on micro/nanoscale tensile testing. Rev Sci Instrum 763:033904. doi:10.1063/1.1865732.

Buehler MJ (2006) Atomistic and continuum modeling of mechanical properties of collagen: Elasticity, fracture, and self assembly. J Mater Res 218:1947–1961. doi:10.1557/jmr.2006.0236.

Acknowledgments

This research conducted in the present study was supported by the National Science Foundation under award no. CTS 0438389 and AFOSR under award no. FA9550-08-1-0372. The authors would also like to acknowledge the Major Research Instrumentation awards by the National Science Foundation, MRI CMS: 0079458 for the acquisition of the Atomic Force Microscope and the Hysitron Triboscope, and MRI CMMI: 0521364 for the scanning electron microscope, gas injection systems, and the nanomanipulators used in the present investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaul, P.B., Singh, U. & Prakash, V. In situ Characterization of Nanomechanical Behavior of Free-standing Nanostructures. Exp Mech 49, 191–205 (2009). https://doi.org/10.1007/s11340-008-9179-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-008-9179-4