Abstract

Elastohydrodynamically lubricated (EHL) contacts rarely exist as single contacts. Multiple contacts or single contacts subjected to the repeated over-rolling represent more often the case in practical applications. A typical example is the rolling element bearing. A lubricant rupture mechanism at each contact outlet determines the lubricant availability to the succeeding contact. This work presents a quantitative description of the lubricant film thickness rupture in EHL contact outlet with the use of the fluorescent microscopy. A rupture ratio of the film thickness between two diverging surfaces exiting the contact was measured for both pure rolling and rolling–sliding conditions. The influence of variation of several parameters such as lubricant properties, rolling speed or rolling element ellipticity to the lubricant rupture ratio was investigated. Understanding of the physical phenomena of the lubricant rupture extends further possibilities in both experimental and theoretical researches of the starved EHL.

Similar content being viewed by others

Abbreviations

- Ca :

-

Capillary number; \(\frac{\eta _{0}U}{\sigma }\)

- \(h_\mathrm{c}\) :

-

Central film thickness

- \(u_{1,2}\) :

-

Entrainment speeds of surfaces

- subscripts 1;2:

-

Relation to the disc;ball

- \(u_\mathrm{m}\) :

-

Mean speed; \((u_1+u_2)/2\)

- SRR:

-

Slide-to-roll ratio; \(\frac{2(u_1-u_2)}{(u_1+u_2)}\)

- k :

-

Ellipticity of the element

- \(\sigma\) :

-

Surface tension

- \(\eta\) :

-

Viscosity at atmospheric pressure

- \(\delta _1\) :

-

Dimensionless film thickness on the disc

- \(\delta _2\) :

-

Dimensionless film thickness on the ball

- \(\varDelta\) :

-

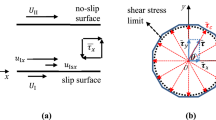

Rupture ratio parameter; \(\frac{\delta _1}{\delta _1+\delta _2}\)

References

Svoboda, P., Kostal, D., Krupka, I., Hartl, M.: Experimental study of starved EHL contacts based on thickness of oil layer in the contact inlet. Tribol. Int. 67, 140–145 (2013)

Lugt, P.M., Morales-Espejel, G.E.: A review of elasto-hydrodynamic lubrication theory. Tribol. Trans. 54(3), 470–496 (2011)

van Zoelen, M.T., Venner, C.H., Lugt, P.M.: The prediction of contact pressure-induced film thickness decay in starved lubricated rolling bearings. Tribol. Trans. 53(6), 831–841 (2010)

Weinstein, S.J., Ruschak, K.J.: Coating rows. Ann. Rev. Fluid Mech. 36, 29–53 (2004)

Savage, M.D.: Cavitation in lubrication—1. On boundary conditions and cavity-fluid interfaces. J. Fluid Mech. 80(pt 4), 743–755 (1977)

Ruschak, K.J.: Boundary conditions at a liquid/air interface in lubrication flow. J. Fluid Mech. 119, 107–120 (1982)

Taroni, M., Breward, C.J.W., Howell, P.D., Oliver, J.M.: Boundary conditions for free surface inlet and outlet problems. J. Fluid Mech. 708, 100–110 (2012)

Coyne, J.C., Elrod JR, H.: Conditions for the rupture of a lubricating film - 1. ASME- Paper 69-Lub-3 (1969)

Coyne, J.C., Elrod Jr, H.: Conditions for the rupture of a lubricating film—2. J. Lubric. Technol. Trans. ASME 93 Ser F(1), 156–167 (1971)

Reynolds, O.: On the theory of lubrication and its application to Mr. Beauchamp Tower’s experiments, including an experimental determination of the viscosity of olive oil. Proc. R. Soc. Lond. 40, 191–203 (1886)

Hewson, R.W.: Free surface model derived from the analytical solution of stokes flow in a wedge. J. Fluids Eng. Trans. ASME 131(4), 0412051–0412055 (2009)

Hewson, R.W., Kapur, N., Gaskell, P.H.: A model for film-forming with Newtonian and shear-thinning fluids. J. Nonnewton. Fluid Mech. 162(1–3), 21–28 (2009)

Lee-Prudhoe, I., Venner, C.H., Cann, P.M., Spikes, H.: Experimental and theoretical approaches to thin film lubrication problems. Solid Mech. Appl. 134, 241–255 (2006)

Chevalier, F., Lubrecht, A.A., Cann, P.M.E., Colin, F., Dalmaz, G.: Starvation phenomena in E.H.L. point contacts. Tribol. Ser. 31, 213–223 (1996)

van Zoelen, M.T., Venner, C.H., Lugt, P.M.: Free surface thin layer flow on bearing raceways. J. Tribol. 130(2), 1–10 (2008)

Bruyere, V., Fillot, N., Morales-Espejel, G.E., Vergne, P.: A two-phase flow approach for the outlet of lubricated line contacts. J. Tribol. 134(4), (2012). doi: 10.1115/1.4006277

Smart, A.E., Ford, R.A.J.: Measurement of thin liquid films by a fluorescence technique. Wear 29(1), (1974)

Sugimura, J., Hashimoto, M., Yamamoto, Y.: Study of elastohydrodynamic contacts with fluorescence microscope. Tribol. Ser. 38, 609–617 (2000)

Lyon, H.O., Prento, P.: Haugland rp. handbook of fluorescent probes and research chemicals, 6th ed. Ugeskrift for laeger 159(27), 4285–4286 (1997)

Azushima, A.: In lubro 3d measurement of oil film thickness at the interface between tool and workpiece in sheet drawing using a fluorescence microscope. Tribol. Int. 38(2), 105–112 (2005)

Acknowledgments

This work is an output of cooperation between Czech Science Foundation under Project No.: 13-30879P and NETME Centre, regional R&D centre built with the financial support from the Operational Programme Research and Development for Innovations within the project NETME Centre (New Technologies for Mechanical Engineering), Reg. No. CZ.1.05/2.1.00/01.0002 and, in the follow-up sustainability stage, supported through NETME CENTRE PLUS (LO1202) by financial means from the Ministry of Education, Youth and Sports under the ‘National Sustainability Programme I’.

Author information

Authors and Affiliations

Corresponding author

Additional information

This article is part of the Topical Collection on STLE Tribology Frontiers Conference 2014.

Rights and permissions

About this article

Cite this article

Košťál, D., Nečas, D., Šperka, P. et al. Lubricant Rupture Ratio at Elastohydrodynamically Lubricated Contact Outlet. Tribol Lett 59, 39 (2015). https://doi.org/10.1007/s11249-015-0565-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-015-0565-7