Abstract

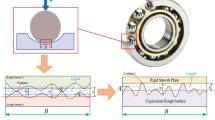

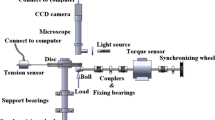

Recent research has identified the novel lubrication scheme brought by boundary slip effect in lubrication. However, the implementation of an endurable slip coating on elastohydrodynamic lubrication (EHL) is challenging. One plausible solution is to mount a slip surface coating onto a substrate with an interlayer, forming a multi-layer structure. This study presents a robust framework for analysing the effects of the thickness and strength of the coating and interlayer. A general algorithm for investigating the mechanics of boundary slip EHL contact that utilises a linear elasticity equation is developed. Besides the influence of boundary slip on the lubrication film, the effect on the mechanical response of the contacting bodies is emphasised.

Similar content being viewed by others

Abbreviations

- a (m):

-

Half Hertzian contact width

- c :

-

Auxiliary variable vector

- E (Pa):

-

Young’s modulus of substrate

- \({E}_{c}\) (Pa):

-

Young’s modulus of surface coating

- E i (Pa):

-

Young’s modulus of interlayer

- f :

-

Critical shear stress and local shear stress difference vector

- h (m):

-

Film thickness

- H :

-

Dimensionless film thickness

- M :

-

Linking matrix

- P (Pa):

-

Lubricant pressure

- \({p}_{h}\) (Pa):

-

Maximum Hertzian contact pressure

- P :

-

Dimensionless pressure

- R (m):

-

Radius of ball (body II)

- t c (m):

-

Coating thickness

- t i (m):

-

Interlayer thickness

- u (m):

-

Elastic deformation of contact bodies along x direction

- \({u}_{\mathrm{I}sx}\) (m/s):

-

Slip velocity along x direction

- \({u}_{\mathrm{I}sy}\) (m/s):

-

Slip velocity along y direction

- \({u}_{\mathrm{I}x}\) (m/s):

-

Fluid velocity along x direction

- \({u}_{\mathrm{I}y}\) (m/s):

-

Fluid velocity along y direction

- u s (m/s):

-

Slip velocity vector

- U :

-

Dimensionless elastic deformation of contact bodies along X direction

- \({U}_{\mathrm{I}}\) (m/s):

-

Velocity of the lower surface

- v (m):

-

Elastic deformation of contact bodies along y direction

- V :

-

Dimensionless elastic deformation of contact bodies along Y direction

- w (m):

-

Elastic deformation of contact bodies along z direction

- W :

-

Dimensionless elastic deformation of contact bodies along Z direction

- \(\alpha\) (Pa− 1):

-

Viscosity-pressure coefficient

- \(\eta\) (Pa s):

-

Viscosity of lubricant

- \({\eta }_{0}\) (Pa s):

-

Ambient viscosity of lubricant

- \(\rho\) (kg m− 3):

-

Density of lubricant

- \({\rho }_{0}\) (kg m− 3):

-

Ambient density of lubricant

- \({\tilde{\sigma }}_{\text{von}}\) :

-

Dimensionless von Mises stress

- \({\tilde{\sigma }}_{xx}\), \({\tilde{\sigma }}_{yy}\), \({\tilde{\sigma }}_{zz}\) :

-

Dimensionless normal stress

- \({\tilde{\sigma }}_{xy}\), \({\tilde{\sigma }}_{xz}\), \({\tilde{\sigma }}_{yz}\) :

-

Dimensionless tangential stress

- \({\tau }_{c}\) (Pa):

-

Critical shear stress

- \({\overline{\tau }}_{c}\) :

-

Dimensionless critical shear stress

- \(\upnu\) :

-

Poisson’s ratio

- \({\nu }_{c}\) :

-

Poisson’s ratio of coating

- \({\upnu }_{i}\) :

-

Poisson’s ratio of interlayer

References

Kaneta, M., Nishikawa, H., Kameishi, K.: Observation of wall slip in elastohydrodynamic lubrication. ASME J. Tribol. 112, 447–452 (1990)

Guo, F., Wong, P.L., Geng, M., Kaneta, M.: Occurrence of wall slip in elastohydrodynamic lubrication. Tribol. Lett. 34, 103–111 (2009)

Wong, P.L., Li, X.M., Guo, F.: Evidence of lubricant slip on steel surface in EHL contact. Tribol. Int. 61, 116–119 (2013)

Wang, P., Reddyhoff, T.: Wall slip in an EHL contact lubricated with 1-dodecanol. Tribol. Int. 113, 197–205 (2017)

Guo, L., Wong, P., Guo, F.: Identifying the optimal interfacial parameter correlated with hydrodynamic lubrication. Friction 4(4), 347–358 (2016)

Thomas, E., Pascovici, M.D., Glovnea, R.P.: Load carrying capacity of a heterogeneous surface bearing. Friction 3(4), 287–293 (2015)

Choo, J.H., Spikes, H.A., Ratoi, M., Glovnea, R., Forrest, A.: Friction reduction in low-load hydrodynamic lubrication with a hydrophobic surface. Tribol. Int. 40(2), 154–159 (2007)

Kalin, M., Kus, M.: New strategy for reducing the EHL friction in steel contacts using additive-formed oleophobic boundary films. Friction 9(6), 1346–1360 (2021)

Guo, F., Wong, P.L.: An anomalous elastohydrodynamic lubrication film: inlet dimple. ASME J. Tribol. 127(2), 425–434 (2005)

Yagi, K., Vergne, P.: Abnormal film shapes in sliding elastohydrodynamic contacts lubricated by fatty alcohols. Proc. Inst. Mech. Eng. Part J 221(3), 287–300 (2007)

Cameron, A.: The viscosity wedge. Trans ASLE 1, 248–253 (1958)

Huang, P., Luo, J., Wen, S.: Theoretical study on the lubrication failure for the lubricants with a limiting shear stress. Tribol. Int. 32(7), 421–426 (1999)

Spikes, H.A.: The half-wetted bearing. Part 1: extended Reynolds equation. Proc. Inst. Mech. Eng. Part J 217(1), 1–14 (2003)

Wong, P.L., Zhao, Y., Mao, J.: Facilitating effective hydrodynamic lubrication for zero-entrainment-velocity contacts based on boundary slip mechanism. Tribol. Int. 128, 89–95 (2018)

Li, X.M., Guo, F., Wong, P.L., Zhao, Y.: Regulation of lubricant supply by wettability gradient in rolling EHL contacts. Tribol. Int. 120, 564–574 (2018)

Liu, C., Guo, F., Wong, P., Li, X.: Laser pattern-induced unidirectional lubricant flow for lubrication track replenishment. Friction (2021). https://doi.org/10.1007/s40544-021-0528-y

Leong, J.Y., Reddyhoff, T., Sinha, S.K., Holmes, A.S., Spikes, H.A.: Hydrodynamic friction reduction in a MAC–hexadecane lubricated MEMS contact. Tribol. Lett. 49(1), 217–225 (2013)

Choo, J.H., Forrest, A.K., Spikes, H.A.: Influence of organic friction modifier on liquid slip: a new mechanism of organic friction modifier action. Tribol. Lett. 27, 239–244 (2007)

Fu, Z., Wong, P.L., Guo, F.: Localized boundary effect on elastohydrodynamic lubricated film shape. Tribol. Lett. 56(3), 471–479 (2014)

Kalin, M., Polajnar, M.: The effect of wetting and surface energy on the friction and slip in oil-lubricated contacts. Tribol. Lett. 52(2), 185–194 (2013)

Qiang, L., Zhang, B., Gao, K., Gong, Z., Zhang, J.: Hydrophobic, mechanical, and tribological properties of fluorine incorporated hydrogenated fullerene-like carbon films. Friction 1, 350–358 (2013)

Wei, C., Chen, C.: The effect of thermal and plastic mismatch on stress distribution in diamond like carbon film under different interlayer/substrate system. Diam. Relat. Mater. 17(7–10), 1534–1540 (2008)

Wang, K., Zhou, H., Zhang, K., Liu, X., Feng, X., Zhang, Y.: Effects of Ti interlayer on adhesion property of DLC films: a first principle study. Diam. Relat. Mater. 111, 108188 (2021)

Habchi, W.: Finite element modeling of elastohydrodynamic lubrication problems. Wiley Blackwell, Hoboken (2018)

Zhao, Y., Wong, P.L., Guo, L.: Linear complementarity solution of 2D boundary slip EHL contact. Tribol. Int. 145, 106178 (2020)

Eaves, B.C.: The linear complementarity problem. Manage. Sci. 17(9), 612–634 (1971)

Chu, L.M., Yu, C.C., Chen, Q.D., Li, W.L.: Elastohydrodynamic lubrication analysis of pure squeeze motion on an elastic coating/elastic substrate system. ASME J. Tribol. 137(1), 011503 (2015)

He, T., Wang, Z., Wu, J.: Effect of imperfect coating on the elastohydrodynamic lubrication: dislocation-like and force-like coating-substrate interfaces. Tribol. Int. 143, 106098 (2020)

Liu, Y., Chen, W.W., Zhu, D., Liu, S., Wang, Q.J.: An elastohydrodynamic lubrication model for coated surfaces in point contacts. ASME J. Tribol. 129(3), 509–516 (2007)

Acknowledgements

This study is supported by the Research Grants Council of Hong Kong (City 11217317), the Applied Research Grant of City University of Hong Kong (Project No.: 9667154), the Scientific Research Startup Fund for Shenzhen High-caliber Personnel of SZPT (No. 6022310045k).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Informed Consent

Informed consent was obtained from all participates included in this study.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Governing Equations for the Boundary slip EHL Contact

Appendix: Governing Equations for the Boundary slip EHL Contact

The dimensionless parameters of the EHL model are derived following the scaling of:

where h is film thickness, R is the radius of Body II, p is pressure, a is the half Hertzian contact width, \({P}_{h}\) is maximum Hertzian contact stress, tc is the thickness of the surface coating, \({\eta }_{0}\) is the ambient viscosity of the lubricant, \({\rho }_{0}\) is the ambient density of the lubricant u, v and w are the elastic deformations. According to [25], to enable a stabilized solution, the weak form for the Reynolds equation and its stabilization terms are:

where Pt is the shape function,

\({\rho }_{ID}\) and \({p}_{f}\) are the coefficients, he is the characteristic length of the mesh, lo is the order of the shape function, and \({\Omega }_{L}\) is the lubrication domain. The penalty term: \({\int }_{{\Omega }_{L}}{p}_{f}{h}_{e}^{2}{P}^{-}{P}_{t}\mathrm{d\Omega }\), is added to restrain the negative pressure in the converged results with very large pf, e.g., pf ~ 106. When solving Eq. 16, we apply zero pressure boundary condition to the boundary of lubrication domain, and zero pressure gradient boundary condition to the axisymmetric boundary.

To obtain elastic deformation, we apply the dimensionless linear elasticity equation for Bodies I and II as:

where \({c}_{1}=\frac{E\left(1-\nu \right)}{\left(1+\nu \right)\left(1-2\nu \right)}\), \({c}_{2}=\frac{E\nu }{\left(1+\nu \right)\left(1-2\nu \right)}\), \({c}_{3}=\frac{E}{2\left(1+\nu \right)}\), \(E\) is the Young’s modulus and \(\nu\) is the Poisson’s ratio. Similarly, the dimensionless linear elasticity equation for the surface coating is:

where cc1, cc2 and cc3 are the elasticity constants of the coating. The boundary conditions for Eqs. 18 and 19 are:

We also implement deformation continuity at the interface of the surface coating and the substrate in the model. After solving Eqs. 18, 19, the dimensionless von Mises stress is obtained:

where \({\tilde{\sigma }}_{xx}\), \({\tilde{\sigma }}_{yy}\) and \({\tilde{\sigma }}_{zz}\) are the dimensionless normal stresses inside the contacting bodies:

\({\tilde{\sigma }}_{xy}\), \({\tilde{\sigma }}_{xz}\) and \({\tilde{\sigma }}_{yz}\) are the dimensionless tangential stresses inside the contacting bodies.

Rights and permissions

About this article

Cite this article

Zhao, Y., Wong, P.L. Influences of Boundary Slip Coating on Elastohydrodynamically Lubricated Contacts. Tribol Lett 70, 54 (2022). https://doi.org/10.1007/s11249-022-01593-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-022-01593-4