Abstract

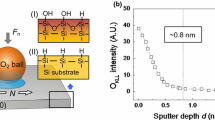

With excellent lubricating property, zinc oxide (ZnO) films are promising candidates to act as protective coatings in Si-based microelectromechanical system devices for the purpose of decreasing friction forces of silicon (Si) material. In this paper, the nanotribological behavior of ZnO films prepared by atomic layer deposition on a Si (100) substrate is investigated by an atomic force microscope. The ZnO films have various thicknesses ranging from 10.0 to 182.1 nm. With the increase of film thickness, the root-mean-square roughness of the films increases, while the ratio of hardness to Young’s modulus (H/E) decreases. Due to their large surface roughness, the thick ZnO films are low in adhesion force. The friction force of the ZnO films is smaller than that of the Si (100) substrate and is greatly influenced by their adhesion force and mechanical property. In a low-load condition, the friction force is dominated by the adhesion force, and thus, the friction force of the ZnO films decreases as film thickness increases. While in a high-load condition, the friction force is dominated by plowing. Films with higher H/E possess smaller friction force, and thus, the friction force increases with the decreasing film thickness.

Similar content being viewed by others

References

Yole développement company home page. http://www.yole.fr/. Accessed 12 Sept 2013

Berman, D., Krim, J.: Surface science, MEMS and NEMS: progress and opportunities for surface science research performed on, or by, microdevices. Prog. Surf. Sci. 88, 171–211 (2013)

Dugger, M.T.: Tribological challenges in MEMS and their mitigation via vapor phase lubrication. Proc. SPIE 8031, 80311H (2011)

Kim, S.H., Asay, D.B., Dugger, M.T.: Nanotribology and MEMS. Nano Today 2, 22–29 (2007)

Weiyuan, W., Yuelin, W., Haifei, B., Bin, X., Minhang, B.: Friction and wear properties in MEMS. Sens. Actuators A A97–98, 486–491 (2002)

Xiang, H., Komvopoulos, K.: Effect of fluorocarbon self-assembled monolayer films on sidewall adhesion and friction of surface micromachines with impacting and sliding contact interfaces. J. Appl. Phys. 113, 224505 (2013)

Laboriante, I., Fisch, M., Payamipour, A., Liu, F., Carraro, C., Maboudian, R.: Morphological, electrical, and chemical changes in cyclically contacting polycrystalline silicon surfaces coated with perfluoroalkylsilane self-Assembled monolayer. Tribol. Lett. 44, 13–17 (2011)

Hook, D.A., Timpe, S.J., Dugger, M.T., Krim, J.: Tribological degradation of fluorocarbon coated silicon microdevice surfaces in normal and sliding contact. J. Appl. Phys. 104, 034303 (2008)

Mani, S.S., Fleming, J.G., Walraven, J.A., Sniegowski, J.J., Se Beer, M.P., Irwin, L.W., Tanner, D.M., LaVan, D.A., Dugger, M.T., Jakubczak, J., Miller, W.M.: Effect of W coating on microengine performance. In: IEEE International Reliability Physics Symposium Proceedings, pp. 146–151 (2000)

Walraven, J.A., Mani, S.S., Fleming, J.G., Headley, T.J., Kotula, P.G., Pimentel, A.A., Rye, M.J., Tanner, D.M., Smith, N.F.: Failure analysis of tungsten coated polysilicon micromachined microengines. Proc. SPIE 4180, 49–57 (2000)

Xiao-An, F., Dunning, J.L., Mehregany, M., Zorman, C.A.: Low stress polycrystalline SiC thin films suitable for MEMS applications. J. Electrochem. Soc. 158, 675–680 (2011)

Anzalone, R., D’Arrigo, G., Camarda, M., Locke, C., Saddow, S.E., La Via, F.: Advanced residual stress analysis and FEM simulation on heteroepitaxial 3C–SiC for MEMS application. J. Microelectromech. Syst. 20, 745–752 (2011)

Radhakrishnan, G., Robertson, R.E., Adams, P.M., Cole, R.C.: Integrated TiC coatings for moving MEMS. Thin Solid Films 420, 553–564 (2002)

Liu, J.F., Nistorica, C., Gory, I., Skidmore, G., Mantiziba, F.M., Gnade, B.E.: Layer-by-layer deposition of zirconium oxide films from aqueous solutions for friction reduction in silicon-based micro electromechanical system devices. Thin Solid Films 492, 6–12 (2005)

Nistorica, C., Liu, J.F., Gory, I., Skidmore, G.D., Mantiziba, F.M., Gnade, B.E., Kim, J.: Tribological and wear studies of coatings fabricated by atomic layer deposition and by successive ionic layer adsorption and reaction for microelectromechanical devices. J. Vac. Sci. Technol. A 23, 836–840 (2005)

Huang, Y.J., Pandraud, G., Sarro, P.M.: Characterization of low temperature deposited atomic layer deposition TiO2 for MEMS applications. J. Vac. Sci. Technol. A 31, 01A148 (2013)

Nistorica, C., Gory, I., Skidmore, G.D.: Friction and wear properties of ALD coated MEMS. In: Material Research Society Symposium Proceedings, 841, R9.16 (2005)

Hoivik, N., Elam, J., Linderman, R., Bright, V.M., George, S., Lee, Y.C.: Atomic layer deposition of conformal dielectric and protective coatings for released micro-electromechanical devices. In: IEEE International Conference on MEMS, pp. 455–458 (2002)

Zabinski, J.S., Sanders, J.H., Nainaparampil, J., Prasad, S.V.: Lubrication using a microstructurally engineered oxide: performance and mechanisms. Tribol. Lett. 8, 103–116 (2000)

Nainaparampil, J.J., Zabinski, J.S.: Lubricity of zinc oxide thin films: study of deposition parameters and Si as an additive. J. Mater. Res. 16, 3423–3429 (2001)

Prasad, S.V., Walck, S.D., Zabinski, J.S.: Microstructural evolution in lubricious ZnO films grown by pulsed laser deposition. Thin Solid Films 360, 107–117 (2000)

Chai, Z.M., Lu, X.C., He, D.N.: Atomic layer deposition of zinc oxide films: effects of nanocrystalline characteristics on tribological performance. Surf. Coat. Technol. 207, 361–366 (2012)

Mohseni, H., Scharf, T.W.: Atomic layer deposition of ZnO/Al2O3/ZrO2 nanolaminates for improved thermal and wear resistance in carbon–carbon composites. J. Vac. Sci. Technol. A 30, 01A149 (2012)

Mohseni, H., Mensah, B.A., Gupta, N., Srinivasan, S.G., Scharf, T.W.: On tailoring the nanocrystalline structure of ZnO to achieve low friction. Tribol. Lubr. Technol. 68, 17–19 (2012)

Mohseni, H., Scharf, T.W.: Tribological improvement of carbon/carbon composites by infiltration of ZnO/Al2O3/ZrO2 solid lubricant coatings. Tribol. Lubr. Technol. 66, 20–21 (2010)

Nainaparampil, J.J., Zabinski, J.S., Prasad, S.V.: Nanotribology of single crystal ZnO surfaces: restructuring at high temperature annealing. J. Vac. Sci. Technol. A 17, 1787–1792 (1999)

Goto, M., Kasahara, A., Konishi, Y., Oishi, T., Tosa, M., Yoshihara, K.: Frictional property of zinc oxide coating films observed by lateral force microscopy. Jpn. J. Appl. Phys. 42, 4834–4836 (2003)

Fang, T.H., Jian, S.R., Chuu, D.S.: Nanotribology and fractal analysis of ZnO thin films using scanning probe microscopy. J. Phys. D Appl. Phys. 36, 878–883 (2003)

Pung, S.Y., Choy, K.L., Hou, X., Shan, C.X.: Preferential growth of ZnO thin films by the atomic layer deposition technique. Nanotechnology 19, 435609 (2008)

Wojcik, A., Godlewski, M., Guziewicz, E., Minikayev, R., Paszkowicz, W.: Controlling of preferential growth mode of ZnO thin films grown by atomic layer deposition. J. Cryst. Growth 310, 284–289 (2008)

Leskela, M., Ritala, M.: Atomic layer deposition (ALD): from precursors to thin film structures. Thin Solid Films 409, 138–146 (2002)

Leskela, M., Ritala, M.: Atomic layer deposition chemistry: recent developments and future challenges. Angew. Chem. Int. Ed. 42, 5548–5554 (2003)

Ritala, M., Leskela, M., Dekker, J.P., Mutsaers, C., Soininen, P.J., Skarp, J.: Perfectly conformal TiN and Al2O3 films deposited by atomic layer deposition. Chem. Vap. Depos. 5, 7–9 (1999)

Jeon, S., Bang, S., Lee, S., Kwon, S., Jeong, W., Jeon, H., Chang, H.J., Park, H.H.: Structural and electrical properties of ZnO thin films deposited by atomic layer deposition at low temperatures. J. Electrochem. Soc. 155, H738–H743 (2008)

Makino, H., Miyake, A., Yamada, T., Yamamoto, N., Yamamoto, T.: Influence of substrate temperature and Zn-precursors on atomic layer deposition of polycrystalline ZnO films on glass. Thin Solid Films 517, 3138–3142 (2009)

Bhushan, B., Sundararajan, S.: Micro/nanoscale friction and wear mechanisms of thin films using atomic force and friction force microscopy. Acta Mater. 46, 3793–3804 (1998)

Ogletree, D.F., Carpick, R.W., Salmeron, M.: Calibration of frictional forces in atomic force microscopy. Rev. Sci. Instrum. 67, 3298–3306 (1996)

Varenberg, M., Etsion, I., Halperin, G.: An improved wedge calibration method for lateral force in atomic force microscopy. Rev. Sci. Instrum. 74, 3362–3367 (2003)

Ott, A.W., Chang, R.: Atomic layer-controlled growth of transparent conducting ZnO on plastic substrates. Mater. Chem. Phys. 58, 132–138 (1999)

Park, S., Lee, Y.E.: Controlling preferred orientation of ZnO thin films by atomic layer deposition. J. Mater. Sci. 39, 2195–2197 (2004)

Park, S., Hwang, C.S., Jeong, H.Y., Chu, H.Y., Cho, K.I.: Transparent ZnO-TFT Arrays fabricated by atomic layer deposition. Electrochem. Solid-State Lett. 11, H10–H14 (2008)

Chai, Z., Liu, Y., Lu, X., He, D.: Reducing adhesion force by means of atomic layer deposition of ZnO films with nanoscale surface roughness. ACS Appl. Mater. Interfaces 6, 3325–3330 (2014)

Bhushan, B., Nosonovsky, M.: Comprehensive model for scale effects in friction due to adhesion and two- and three-body deformation (plowing). Acta Mater. 52, 2461–2474 (2004)

Tsui, T.Y., Pharr, G.M.: Substrate effects on nanoindentation mechanical property measurement of soft films on hard substrates. J. Mater. Res. 14, 292–301 (1999)

Ni, W.Y., Cheng, Y.T., Lukitsch, M.J., Weiner, A.M., Lev, L.C., Grummon, D.S.: Effects of the ratio of hardness to Young’s modulus on the friction and wear behavior of bilayer coatings. Appl. Phys. Lett. 85, 4028–4030 (2004)

Leyland, A., Matthews, A.: On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour. Wear 246, 1–11 (2000)

Peng-zhe, Z., Yuan-zhong, H., Tian-bao, M., Hui, W.: Molecular dynamics study on friction due to ploughing and adhesion in nanometric scratching process. Tribol. Lett. 41, 41–46 (2011)

Acknowledgments

The authors greatly appreciate the financial support of the National Science Fund for Distinguished Young Scholars (50825501), the Science Fund for Creative Research Groups (51321092), the National Natural Science Foundation of China (51335005), and the National Science and Technology Major Project (2008ZX02104-001). Helpful discussions with Wen Jing are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chai, Z., Liu, Y., Lu, X. et al. Reducing Friction Force of Si Material by Means of Atomic Layer-Deposited ZnO Films. Tribol Lett 56, 67–75 (2014). https://doi.org/10.1007/s11249-014-0383-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11249-014-0383-3