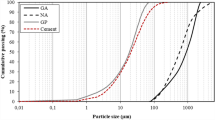

The effect of alkali-containing additive of water soluble lump silicate on the degree of cristobalitization and thermal expansion of specimens based on fuzed quartz HCBS is studied. The additive content (for Na20) is varied within the limits of 0.1 – 2.0% or from 0.025 to 0.50%. In specimens given prior nonisothermal heating to 1500°C the cristobalite content is from 32 – 34% (specimens without additive) to 88 and 96% (specimens with 1 and 2% additive). Specimen maximum thermal expansion corresponding to transition of low-temperature into high-temperature cristobalite occurs within a limited range of 150 – 300°C.

Similar content being viewed by others

References

Yu. E. Pivinskii and E. I. Sudal’tsev, Quartz Ceramics and Refractories. In 2 Vol., Vol. 1. Theoretical Bases and Engineering Processes (Yu. E. Pivinskii, editor) [in Russian], Teploénergetik, Moscow (2008).

Yu. E. Pivinskii, P. V. Dyakin, and A. Yu. Kolobov, “Research in the area of preparing materials based on fuzed quartz HCBS. Part 8. Effect of alkali additions on ceramic sintering and cristobalitization in a nonisothermal heating regime,” Novye Ogneupory, No. 1, 22 – 28 (2016).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the area of preparing materials based on fuzed quartz HCBS. Part 1. Comparative evaluation and distinguishing features of quarts ceramic and refractory technology,” Refract. Indust. Ceram., 55(4), 311 – 317 (2014).

Yu. E. Pivinskii, “Research in the area of preparing materials based on fuzed quartz HCBS. Part 2. Quartz steel-pouring refractories,” Refract. Indust. Ceram., 56(1), 20 – 25 (2015).

Yu. E. Pivinskii and E. I. Sudal’tsev, Quartz Ceramics and Refractories. In 2 Vol., Vol. 2. Materials, Their Properties and Fields of Application (Yu. E. Pivinskii, editor) [in Russian], Teploenergetik, Moscow (2008).

Yu. E. Pivinskii, Rheology of Dispersed Systems, HCBS, and Ceramic Concretes [in Russian], Politekhnika, St. Petersburg (2012).

O. K. Botvinkin and A I. Zaporozhskii, Quartz Glass [in Russian], Stroizdat (1965).

V. P. Pryatnishnikov, The Silica System [in Russian], Izd. Lit. po Stroit., Leningrad (1971).

N. A. Toropov, V. P. Barzakovskii, and V. V. Lapin, Silicate System Composition Diagrams [in Russian], Nauka, Moscow-Leningrad (1965).

G. V. Samsonov (editor) Physicochemical Properties of Oxides: Handbook [in Russian], Metallurgiya, Moscow (1978).

I. S. Kainarskii, Dinas [in Russian], Gosizdat po Chern. Tsvet. Met., Moscow (1961).

D. I. Garshin (editor) Refractory Production: Handbook [in Russian], Metallurgiya, Moscow (1965).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the area of preparing materials based on fuzed quartz HCBS. Part 4. Study of isothermal and nonisotermal sintering kinetics,” Refract. Indust. Ceram., 56(2), 172 – 179 (2015).

Yu. E. Pivinskii and P. V. Dyakin, “Research in the area of preparing materials based on fuzed quartz HCBS. Part 6. Effect of firing temperature on material sintering and cristobalitization,” Refract. Indust. Ceram., 56(4), 366 – 373 (2015).

Yu. E. Pivinskii and P. V. Dyakin, ““Research in the area of preparing materials based on fuzed quartz HCBS. Part 7. Study of sintering and cristobalitization of centrifugally molded refractories,” Novye Ogneupory, No. 9, 16 – 24 (2015).

T. I. Litovskaya, Yu. E. Pivinskii, F. S. Kaplan, et al., “Features of the thermophysical properties a highly concentrated ceramic binder suspension-base unfired quartz ceramic,” Refractories, 30(11/12), 701 – 705 (198).

Yu. E. Pivinskii, Theoretical Aspects of Ceramic and Refractory Technology, Vol. 1 [in Russian], Stroizdat, St. Petersburg (2003).

Yu. E. Pivinskii, A. M. Gorokhovskii, and A. V. Makarov, “Record-breaking durability of quartz protecting tubes for steel teeming tested under service conditions,” Refract. Indust. Ceram., 46(1), 27 – 28 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

1Part 1 of the article was published in Novye Ogneupory No. 7 (2014), parts 2 – 7 in Nos. 1, 3, 4, 6, 7, and 9 (2015), and part 8 in No. 1 (2016).

Translated from Novye Ogneupory, No. 3, pp. 123 – 128, March 2016.

Rights and permissions

About this article

Cite this article

Pivinskii, Y.E., Dyakin, P.V. & Kolobov, A.Y. Research in the Area of Preparing Materials Based on Fuzed Quartz HCBS. Part 9. Effect of Alkali Additions on Material Cristobalitization and Thermal Expansion After Nonisothermal Heating1 . Refract Ind Ceram 57, 135–140 (2016). https://doi.org/10.1007/s11148-016-9942-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-016-9942-5