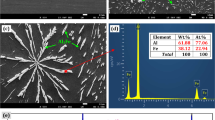

The paper analyzes how the antifriction composites produced from AK12MMgN silumin grinding waste with MoS2 solid lubricant additions acquire their structure and porosity. The materials are intended to perform in friction joints at elevated loads of 2.0–4.0 MPa and sliding velocities of 1.0−3.0 m/s in air. It is shown how the process developed for producing these materials influences their structure and tribotechnical properties. The distribution of MoS2 in the AK12MMgN-matrix composite, its role in the self-lubrication mechanism, and the distribution of MoS2 and chemical elements of the friction joint in the contact zone in the sliding friction conditions corresponding to actual operation of joints in a printing machine are studied. The solid lubricant is uniformly distributed over the friction surfaces and thus covers the entire friction zone in the friction process. The tribological films formed in the presence of a MoS2 solid lubricant promote high antifriction properties of the composite produced from silumin waste. These properties allow the operational conditions to be improved and extend the application of new wear-resistant materials produced from recycled materials in contact joints of printing machines.

Similar content being viewed by others

References

P.O. Kirichok, T.A. Roik, A.P. Gavrish, A.V. Shevchuk, and Yu.Yu. Vitsyuk, Novel Composition Materials for Friction Parts of Printing Machines [in Ukrainian], NTUU Kyiv Politech. Inst., Kyiv (2015), p. 428.

A.G. Kostornov, Tribotechnical Materials Science [in Russian], Knowledge, Lugansk (2012), p. 696.

Powder Metal Technologies and Applications, ASM Handbook, Vol. 7, The Materials International Society, New York, USA (1998), p. 1146.

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, and A. Vieregge, “Recent development in aluminum alloys for the automotive industry,” Mater. Sci. Eng., 280, No. 1, 37–49 (2011).

Kumar Shivendra, Fabrice Mathieux, Godfrey Onwubolu, and Vineet Chandra, “A novel powder metallurgy-based method for the recycling of aluminum adapted to a small island developing state in the pacific,” Int. J. Environ. Conscious Des. Manuf., No. 13, 1–22 (2007).

Muchová Lenka and Peter Eder, End-of-waste Criteria for Aluminum and Aluminum Alloy Scrap: Technical Proposals, Institute for Prospective Technological Studies, Publications Office of the European Union, Luxembourg (2010), p. 66.

S. Hywon, H. Dong, and B. Kim, “Manufacturing of aluminum flake powder from foil scrap by dry ball milling process,” J. Mater. Process. Technol., No. 9, 105−109 (2000).

T.A. Roik, A.P. Gavrish, O.N. Gavrish, V.V. Kholyavko, and O.M. Prokhorenko, “Composite aluminum-based bearing material,” Ukrainian Patent 34407, IPC C22C 21/02 (2008.01); appl. and owned NTUU Kyiv Politech. Inst., No. u200803173; appl. March 12, 2008; publ. August 11, 2008; Bulletin No. 15, p. 3.

T.A. Roik and I.E. Dorfman, “Development of process methods for producing bearing antifriction parts for printing machines,” in: Advanced Mechanical Engineering Technologies and Systems (International Collection of Scientific Papers) [in Russian], DonGTU, Donetsk (2012), Issue 44, pp. 219–225.

T. Wejrzanowski, “Computer program micrometer,” Mater. Sci., No. 23, 28–34 (2005).

A.P. Gulyaev, Metallurgical Science: University Textbook [in Russian], 6th ed., Metallurgiya, Moscow (1986), p. 544.

A.P. Smirnyagin, Industrial Nonferrous Metals and Alloys [in Russian], Metallurgiya, Moscow (1974), p. 246.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 57, Nos. 9–10 (523), pp. 37–46, 2018.

Rights and permissions

About this article

Cite this article

Roik, T.A., Gavrysh, O.A. & Vitsiuk, Y.Y. The Functional Properties Acquired by Antifriction Composites Produced from Silumin Grinding Waste. Powder Metall Met Ceram 57, 526–532 (2019). https://doi.org/10.1007/s11106-019-00011-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-019-00011-0