Abstract

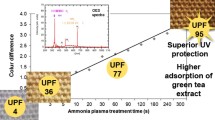

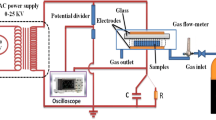

The present study describes surface modification of leather using environment friendly atmospheric pressure dielectric barrier discharge (DBD) process to improve dyeing with natural dyes. Leather samples were exposed to dielectric barrier discharge produced in air. DBD plasma treatment changes morphology and chemical composition of the surface of leather samples. The chemical changes at leather surface are confirmed by Fourier transform infrared spectrometer. The morphology and chemical composition of leather surface is studied using scanning electron microscope and X-ray photoelectron spectroscopy. We observed significant improvement in dye uptake properties after air plasma treatment. Different species formed in plasma are identified using optical emission spectroscopy. Untreated and plasma treated samples were dyed with Eco-Garnet Brown, Eco-Hill Brown III, Eco-Turkey Red and Eco-Smoke Grey natural dyes. Dyeing behavior was assessed by spectroscopic measurement and by measuring fastness (wash and rub) properties. This has clearly indicated an increase in color intensity of plasma exposed leather as well as an increase in the dye uptake as compared to the untreated leather. Best results were obtained with Eco-Hill Brown III and Eco-Smoke Grey dyes. The study reveals that atmospheric pressure plasma has potential to become dry and eco-friendly process to modify leather surface to improve dye uptake properties with natural dyes.

Similar content being viewed by others

References

Haroun AA, Mansour HF (2008) New approaches for the reactive dyeing of the retanned carbohydrate crust leather. Dyes Pigm 76:213–219

Sivakumar V, Rao PG (2003) Studies on the use of power ultrasound in leather dyeing. Ultrason Sonochem 10:85–94

Sivakumar V, Swaminathan G, Rao PG, Ramasami T (2009) Sono-leather technology with ultrasound: a boon for unit operations in leather processing—review of our research work at Central Leather Research Institute (CLRI), India. Ultrason Sonochem 16:116–119

Kanth SV, Venba R, Madhan B, Chandrababu NK, Sadulla S (2008) Studies on the influence of bacterial collagenase in leather dyeing. Dyes Pigm 76:338–347

Kanth SV, Venba R, Jayakumar GC, Chandrababu NK (2009) Kinetics of leather dyeing pretreated with enzymes: role of acid protease. Bioresour Technol 100:2430–2435

Joseph K, Nithya N (2009) Material flows in the life cycle of leather. J Clean Prod 17:676–682

Sivakumar V, Anna JL, Vijayeeswarri J, Swaminathan G (2009) Ultrasound assisted enhancement in natural dye extraction from beetroot for industrial applications and natural dyeing of leather. Ultrason Sonochem 16:782–789

Velmurugan P, Kamala-Kannan S, Balachandar V, Lakshmanaperumalsamy P, Chae J-C, Oh B-T (2010) Natural pigment extraction from five filamentous fungi for industrial applications and dyeing of leather. Carbohydr Polym 79:262–268

Selvi AT, Aravindhan R, Madhan B, Rao JR (2013) Studies on the application of natural dye extract from Bixa orellana seeds for dyeing and finishing of leather. Ind Crops Prod 43:84–86

Onem E, Gulumser G, Ocak B (2011) Evaluation of natural dyeing of leather with Rubia tinctorum extract. Ekoloji 20:81–87

Rao JR, Prakash A, Thangaraj E, Sreeram KJ, Saravanabhavan S, Nair BU (2008) Natural dyeing of leathers using natural materials. J Am Leather Chem Assoc 103:68–75

Musa AE, Madhan B, Madhulatha W, Raghava RJ, Gasmelseed GA, Sadulla S (2009) Coloring of leather using henna—natural alternative material for dyeing. J Am Leather Chem. Assoc. 104:183–190

Bechtold T, Turcanu A, Ganglberger E, Geissler S (2003) Natural dyes in modern textile dye houses—how to combine experiences of two centuries to meet the demands of the future? J Clean Prod 11(5):499–509

Samanta A, Agarwal P (2009) Application of natural dyes on textiles. Indian J Fiber Text Res 34:384–399

Shahid M, Shahid-ul-Islam Mohammad F (2013) Recent advancements in natural dye applications: a review. J Clean Prod 53:310–331

Morent R, Geyter ND, Verschuren J, Clerck KD, Kiekens P, Leys C (2008) Non-thermal plasma treatment of textiles. Surf Coat Technol 202:3427–3449

Kale KH, Desai AN (2011) Atmospheric pressure plasma treatment of textiles using non-polymerising gases. Indian J Fibre Text Res 36:289–299

Acikel S, Aslan A, Oksuz L, Aktan T (2013) Effects of atmospheric pressure plasma treatments on various properties of leathers. J Am Leather Chem Assoc 108:266–276

Choi JH, Lee ES, Baik HK, Lee SJ, Song KM, Hwang MK, Huh CS (2002) Surface modification of natural leather using low-pressure parallel plate plasma. Surf Coat Technol 171:257–263

Osin YN, Makhotkina LY, Abutalipova LN, Abdullin IS (1998) SEM and X-ray analysis of surface microstructure of a natural leather processed in a low temperature plasma. Vacuum 51:221–225

Choi JH, Lee TI, Han I, Baik HK, Song KM, Lim YS, Lee ES (2006) Investigation of the transition between glow and streamer discharges in atmospheric air. Plasma Sour Sci Technol 15:416–420

Srivastava AK, Garg MK, Prasad KSG, Kumar V, Chowdhuri MB, Prakash R (2007) Characterization of atmospheric pressure glow discharge in helium using langmuir probe, emission spectroscopy, and discharge resistivity. IEEE Trans Plasma Sci 35:1135–1142

Lofthus A, Krupenie PH (1977) The spectrum of molecular nitrogen. J Phys Chem Ref Data 6:113–307

Nassar H, Pellerin S, Musiol K, Martinie O, Pellerin N, Cormier JM (2004) N2 +/N2 ratio and temperature measurements based on the first negative N2 + and second positive N2 overlapped molecular emission spectra. J Phys D Appl Phys 37:1904

Mahoney J, Zhu W, Johnson VS, Becker KH, Lopez JL (2010) Electrical and optical emission measurements of a capillary dielectric barrier discharge. Eur Phys J D 60:441–447

Lianzhu Z, Shuxia Z, Xiulan M (2008) Characterization of nitrogen glow discharge plasma via optical emission spectrum simulation. Plasma Sci Technol 10:455

Fang Z, Qiu Y, Sun Y, Wang H, Edmund K (2008) Experimental study on discharge characteristics and ozone generation of dielectric barrier discharge in a cylinder–cylinder reactor and a wire–cylinder reactor. J Electrostat 66:421–426

Wang C, Zhang G, Wang X, He X (2010) The effect of air plasma on barrier dielectric surface in dielectric barrier discharge. Appl Surf Sci 257:1698–1702

Kogelschatz U, Eliasson B, Hirth M (1988) Ozone generation from oxygen and air: discharge physics and reaction mechanisms. Ozone Sci Eng 10:367–377

Kogelschatz U (2003) Dielectric-barrier discharges: their history, discharge physics, and industrial applications. Plasma Chem Plasma Process 23:1–46

Becker KH, Kogelschatz U, Schoenbach KH, Barker RJ (2004) Non-equilibrium air plasmas at atmospheric pressure, series in plasma physics and fluid dynamics. Taylor & Francis, Boca Raton

Petibois C, Gouspillou G, Wehbe K, Delage J-P, Déléris G (2006) Analysis of type I and IV collagens by FT-IR spectroscopy and imaging for a molecular investigation of skeletal muscle connective tissue. Anal Bioanal Chem 386:1961–1966

de Vidal BC, Mello MLS (2011) Collagen type I amide I band infrared spectroscopy. Micron 42:283–289

Belbachir K, Noreen R, Gouspillou G, Petibois C (2009) Collagen types analysis and differentiation by FTIR spectroscopy. Anal Bioanal Chem 395:829–837

Nashy EHA, Osman O, Mahmoud AA, Ibrahim M (2012) Molecular spectroscopic study for suggested mechanism of chrome tanned leather. Spectrochim Acta Part A Mol Biomol Spectrosc 88:171–176

Chung C, Lee M, Choe EK (2004) Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr Polym 58:417–420

García JL, Asadinezhad A, Pacherník J, Lehocký M, Junkar I, Humpolíček P, Sáha P, Valášek P (2010) Cell proliferation of HaCaT keratinocytes on collagen films modified by argon plasma treatment. Molecules 15:2845–2856

Samouillan V, Merbahi N, Yousfi M, Gardou J-P, Delaunay F, Dandurand J, Lacabanne C (2012) Effect of low-temperature plasma jet on thermal stability and physical structure of type I collagen. IEEE Trans Plasma Sci 40:1688–1695

He L, Mu C, Shi J, Zhang Q, Shi B, Lin W (2011) Modification of collagen with a natural cross-linker, procyanidin. Int J Biol Macromol 48:354–359

Şulea D, Albu MG, Leca M, Mihalache M, Popa L, Ghica MV (2012) Collagen-thuja tincture biomaterials for wound treatment. 4. Porous matrices containing thuja tincture and chlorhexidine digluconate. Rev Roum Chim 57:569–575

Andrews M, Murali J, Muralidharan C, Madhulata W, Jayakumar R (2003) Interaction of collagen with corilagin. Colloid Polym Sci 281:766–770

Cataldo F (2003) On the action of ozone on proteins. Polym Degrad Stab 82:105–114

Cataldo F (2007) On the action of ozone on gelatin. Int J Biol Macromol 41:210–216

Liu C, Shen SZ, Han Z (2011) Surface wettability and chemistry of ozone perfusion processed porous collagen scaffold. J Bionic Eng 8:223–233

Acknowledgment

The authors are thankful to Department of Science and Technology, Government of India for providing financial support for this research work. The authors are thankful to Dr. Mukhrejee, Head, FCIPT division for providing support and motivation. The authors are thankful to UGC-DAE Indore for valued support in terms of XPS Characterization and ATIRA, Ahmadabad for providing service for spectroscopic and fastness analysis of dyed leather samples. The authors are highly thankful to Ms. Purvi Kikani and Ms. Nisha Chandwani, Officials at FCIPT for their all times support and Co-operations. The authors specially acknowledge the generous support of Dr. Deepti Sethia for assisting in XPS analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dave, H., Ledwani, L. & Nema, S.K. Surface Modification by Atmospheric Pressure Air Plasma Treatment to Improve Dyeing with Natural Dyes: An Environment Friendly Approach for Leather Processing. Plasma Chem Plasma Process 36, 599–613 (2016). https://doi.org/10.1007/s11090-015-9687-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11090-015-9687-9