Abstract

The effects of steam on the oxidation behavior of model Al2O3-scale forming Ni-base alloys at 1000 °C were studied. This was done by conducting tests using dry air and air +30 % H2O (“wet air” in short) gas environments. It was found that the critical concentration of Al (N *Al ) to form a continuous and protective alumina scale on Ni–Al–Cr alloys is increased when the environment is wet air. Based on a rigorous assessment of the parameters contained in Maak’s modification (Z Met 52:545, 1961) of Wagner’s criterion (Z Elektrochem 63:772, 1959) for the transition from internal oxidation to external scale formation, it was deduced that the factor that can change the critical concentration N *Al to the extent measured is the critical volume fraction f *v .

Similar content being viewed by others

References

F. S. Pettit, Transactions of the Metallurgical Society of AIME 239, 1296 (1967).

C. S. Giggins and F. S. Pettit, Journal of the Electrochemical Society 118, 1782 (1971).

I. A. Kvernes and P. Kofstad, Metallurgical Transactions 3, 1511 (1972).

M. C. Maris-Sida, G. H. Meier and F. S. Pettit, Metallurgical and Materials Transactions A 34A, 2609 (2003).

R. Janakiraman, G. H. Meier and F. S. Pettit, Metallurgical and Materials Transactions A 30A, 2905 (1999).

F. A. Elrefaie, A. Manolescu and W. W. Smeltzer, Journal of the Electrochemical Society 132, 2489 (1985).

H. C. Yi, S. W. Guan, W. W. Smeltzer and A. Petric, Acta Metallurgica et Materialia 42, 981 (1994).

J. A. Nesbitt, Journal of the Electrochemical Society 136, 1511 (1989).

J. A. Nesbitt, Journal of the Electrochemical Society 136, 1518 (1989).

F. Gesmundo and F. Viani, Oxidation of Metals 25, 269 (1986).

F. Gesmundo, F. Viani and Y. Niu, Oxidation of Metals 42, 285 (1994).

Y. Niu and F. Gesmundo, Oxidation of Metals 65, 329 (2006).

S. Wang, F. Gesmundo and Y. Niu, Oxidation of Metals 72, 279 (2009).

C. Wagner, Zeitschrift für Elektrochemie 63, 772 (1959).

F. Maak, Zeitschrift für Metallkunde 52, 545 (1961).

C. Wagner, Journal of the Electrochemical Society 103, 571 (1956).

M. A. Alvin, Department of Energy, National Energy Technology Laboratory, Pittsburgh, PA, USA (private communication).

E. Essuman, G. H. Meier, J. Zurek, M. Hansel and W. J. Quadakkers, Oxidation of Metals 69, 143 (2008).

J. Zurek, M. Michalik, F. Schmitz, T.-U. Kern, L. Singheiser and W. J. Quadakkers, Oxidation of Metals 63, 401 (2005).

S. Hayashi and T. Narita, Oxidation of Metals 56, 251 (2001).

A. Rahmel and T. Tobolshi, Corrosion Science 5, 333 (1965).

J. Ehlers, D. J. Young, E. J. Smaardijk, A. K. Tyagi, H. J. Penkella, L. Singheiser and W. J. Quadakkers, Corrosion Science 48, 3428 (2006).

A. Galerie, S. Henry, Y. Wouters, M. Mermoux, J. P. Petit and L. Anton, Materials at High Temperature 22, 105 (2005).

Y. Ikeda and K. Nii, Transactions of National Research Institute for Metals 26, 52 (1984).

W. Zhao, Ph.D thesis, University of Pittsburgh, (2012).

W. Zhao and B. Gleeson, Oxidation of Metals 79, 613 (2013).

F. H. Stott, G. C. Wood, D. P. Whittle, B. D. Bastow, Y. Shida and A. Martinez-Villafane, Solid State Ionics 12, 365 (1984).

J. L. Meijering, Advances Materials Research 5, 81 (1971).

J. Megusar and G. H. Meier, Metallurgical Transactions A 7A, 1133 (1976).

M. Ueda, Y. Inoue, H. Ochiai, M. Takeyama and T. Maruyama, Oxidation of Metals 79, 485 (2013).

G. C. Wood, F. H. Stott, D. P. Whittle, Y. Shida and B. D. Bastow, Corrosion Science 2, 9 (1983).

M. C. Maris-Sida, Ph.D thesis, University of Pittsburgh, (2004).

H. V. Atkinson, Materials Science and Technology 4, 1052 (1988).

R. Haugsrud, Corrosion Science 45, 211 (2003).

H. E. Evans, Materials Science and Technology 4, 1089 (1988).

F. H. Stott and G. C. Wood, Materials Science and Technology 4, 1072 (1988).

R. T. DeHoff, F. N. Rhines, Quantitative Microscopy. (Herndon 46 1991).

A. R. Setiawan, M. Hanafi, B. Ani, M. Ueda, K. Kawamura and T. Maruyama, ISIJ International 50, 259 (2010).

E. Wimmer, W. Wolf, J. Sticht, P. Saxe, C. B. Geller, R. Najafabadi and G. A. Young, Physical Review B 77, 134305 (2008).

H. Z. Fang, S. L. Shang, Y. Wang, Z. K. Liu, D. Alfonso, D. E. Alman, Y. K. Shin, C. Y. Zou, A. C. T. van Duin, Y. K. Lei and G. F. Wang, Journal of Applied Physics 115, 043501 (2014).

D. Alfonso, Department of Energy, National Energy Technology Laboratory, Pittsburgh, PA, USA (private communication).

C. Kluthe, T. Al-Kassab, J. Barker, W. Pyckhout-Hintzen and R. Kirchheim, Acta Materialia 52, 2701 (2004).

R. Kirchheim, A. Pundt, T. Al-Kassab, F. Wang and C. Kluthe, Zeitschrift für Metallkunde 94, 266 (2003).

J. Park and C. J. Altstetter, Metallurgical Transactions A 18A, 43 (1987).

F. A. Elrefaie and W. W. Smeltzer, Journal of the Electrochemical Society 128, 2237 (1981).

K. P. Trumble and M. Ruhle, Acta Metallurgica et Materialia 39, 1915 (1991).

W. Gust, H. B. Hintz, A. Lodding, H. Odelius and B. Predel, Physica Status Solidi A 64, 187 (1981).

A. Green and N. Swindells, Materials Science and Technology 1, 101 (1985).

M. M. P. Janssen, Metallurgical Transactions 4, 1623 (1973).

Acknowledgments

This research is supported by the U.S. Office of Naval Research, award N000014-09-1-1127 and managed by Dr. David Shifler. The authors wish to thank Professor David Young at the University of New South Wales, Australia, for his constructive suggestions.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1

In Wagner’s theory, γ is defined in such a way that the internal oxidation rate of dilute alloy is assumed to follow a parabolic law in the form of:

Based on this definition, Wagner studied the mass balances at the internal oxidation front and found that γ can be calculated by solving the following equation:

where N SO is the oxygen solubility on the alloy surface, G(r) is auxiliary function with the form of \(G(r) = \pi^{1/2} r\exp (r^{2} )erf(r)\) and N oAl is the Al concentration in the alloy.

It is seen that γ is a function of N oAl while the critical concentration N *Al,1 is a function of γ. However, the value of N *Al,1 , which is a unique value for Ni–Al alloy system under a given exposure condition, should have nothing to do with the N oAl . Therefore, there should be an iteration process to determine the N *Al,1 . This iteration process starts with a small N oAl value. Taking this value into Eq. A2 yields a γ value. Then, taking this γ value into Eq. 1 of the main text yields a N *Al,1 . If the N oAl is much smaller than N *Al,1 , N oAl needs to be increased and N *Al,1 is calculated for the new N oAl . The iterations are completed when N oAl equals N *Al,1 .

Appendix 2

Determining the Effective Oxygen Diffusivity DO,eff in the Internal Oxidation Zone

Park and Altstetter [44] measured the oxygen diffusion coefficient in solid γ-Ni by a solid-state electrochemical method. It was found the diffusivity of oxygen in nickel is:

This corresponds to the oxygen diffusivity in a clean bulk nickel matrix. At 1000 °C, D O = 9.1 × 10−9 cm2/s. The effective diffusion coefficient of oxygen in the IOZ should consider the contribution from the internal oxide/alloy matrix interfaces. From a study by Stott et al. [27], the effective diffusion coefficient of oxygen can be calculated by:

where the D O is the oxygen diffusion coefficient in the nickel matrix, D O,i is the interfacial diffusion coefficient, N BOv is the mole fraction of oxide, V ox and V all are the molar volume of the oxide and the alloy, δ i is the width of the interface and r is the radius of the precipitates. From the data used by Stott et al. [27]., V ox = 19.5 cm3, V all = 6.67 cm3, δ i was assumed to be 1 nm, which is typically the width assumed for grain-boundary diffusion study and D O,i/D O was found to be 8.0x103 at 1000 °C. r is measured from Fig. 8 and is determined to be around 0.25 μm. Substituting all these data into Eq. A4, the effective oxygen diffusion coefficient in the internal oxidation zone for Ni-3 at.% Al alloy is calculated to be D O,eff = 1.0x10−7 cm2/s.

Determining the Oxygen Solubility N SO from Thermodynamics

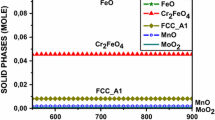

When there is an external NiO scale present, the oxygen solubility N SO is no longer determined by the exterior gas environment, but by the equilibria established at the alloy/scale interface. This equilibrium is not the one for the γ-Ni and NiO. Rather, because of the presence of the Al in the alloy, the equilibria are established by three phases: γ-Ni, NiO and the spinel NiAl2O4. This can be shown by a schematic of an isothermal cross section of the ternary phase diagram for Ni–Al–O at 1000 °C, Fig. 13. The oxygen solubility for our case should correspond to the point B on this ternary phase diagram. Elrefair and Smeltzer [45] determined the oxygen partial pressure corresponding to the three-phase equilibria between 1123 and 1423 K based on electrochemical measurements on a Ni,NiO,NiAl2O4|ZrO2(+CaO)|Ni,NiO cell and it follows the relation:

At 1000 °C, the oxygen pressure corresponding to γ-Ni/NiO/NiAl2O4 coexistence is 4.1 × 10−11atm. This oxygen partial pressure is slightly lower than the one corresponding to point A, 4.5 × 10−11atm, which is the dissociation pressure of oxygen for NiO equilibrated with Ni. Further, the Gibbs free energy change for the reaction:

was found [46] to be:

when O uses 1 at.% standard state, which equals 100 × N SO . Therefore, the oxygen solubility corresponding to the oxygen partial pressure for three-phase equilibria at 1000 °C is determined to be N SO = 4.1 × 10−4.

Determining the Diffusion Coefficient of Aluminum DAl in Nickel

This diffusion coefficient D Al in Ni has been reported in several papers [47–49]. At around 1000 °C, the D Al values from those papers are in fairly good agreement. An accurate temperature dependence is deduced to be [47]:

At 1000 °C, D Al is 2.1 × 10−11 cm2/s.

Determining the Dimensionless Parameter u and γ

The values of u and γ can be determined experimentally from the thickness of the metal recession zone and internal oxidation zone observed on the cross-sectional images. In dry air, by using D O,eff found previously, u dry and γ dry were determined to be u dry = 0.0098 and γ dry = 0.082.

Rights and permissions

About this article

Cite this article

Zhao, W., Gleeson, B. Assessment of the Detrimental Effects of Steam on Al2O3-Scale Establishment. Oxid Met 83, 607–627 (2015). https://doi.org/10.1007/s11085-015-9541-8

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-015-9541-8