Abstract

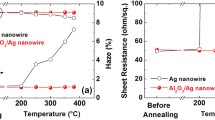

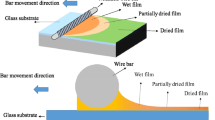

Lowering the sintering temperature of nanoparticles in the electrode deposition process holds both academic and industrial interest because of the potential applications of such electrodes in polymer devices and flexible electronics. In addition, achieving uniform electrode formation after ligand exchange is equally important as lowering the sintering temperature. Here, we report a simple chemical treatment by the addition of ligand-exchanging interfaces to lower the sintering temperature; we also determine the optimum extent of ligand exchange for crack-free electrode formation. First, we investigated the structural change of Ag thin films with respect to the concentration of acrylic acid (AA) solutions. Second, we used thermal analysis to evaluate the effects of changes in the sintering temperature. We observed that the resulting conductivity of the Ag patterns was only one order of magnitude lower than that of bulk Ag when the patterns were sintered at 150 °C. The simple chemical treatment developed in this work for solution-processed Ag electrode formation can be adopted for flexible electronics, which would eliminate the need for vacuum and high-temperature processes.

We report the optimum extent of ligand exchange on Ag nanoparticles from oleylamine to acrylic acid for achieving uniform Ag thin film and low-temperature sintering.

Similar content being viewed by others

References

Allen M, Alastalo A, Suhonen M, Mattila T, Leppaniemi J, Seppa H (2011) Contactless electrical sintering of silver nanoparticles on flexible substrates. IEEE Trans Microw Theory Tech 59:1419–1429. doi:10.1109/TMTT.2011.2123910

Ankireddy K, Vunnam S, Kellar J, Cross W (2013) Highly conductive short chain carboxylic acid encapsulated silver nanoparticle based inks for direct write technology applications. J Mater Chem C 1:572–579. doi:10.1039/c2tc00336h

Braun D, Heeger AJ (1991) Visible light emission from semiconducting polymer diodes. Appl Phys Lett 58:1982. doi:10.1063/1.105039

Cao Y, Yu G, Parker ID, Heeger AJ (2000) Ultrathin layer alkaline earth metals as stable electron-injecting electrodes for polymer light emitting diodes. J Appl Phys 88:3618. doi:10.1063/1.1289518

Chen M, Feng YG, Wang X, Li TC, Zhang JY, Qian DJ (2007) Silver nanoparticles capped by oleylamine: formation, growth, and self-organization. Langmuir 23:5296–5304. doi:10.1021/la700553d

Ding J et al (2016) Preparing of highly conductive patterns on flexible substrates by screen printing of silver nanoparticles with different size distribution. Nanoscale Res Lett 11:412. doi:10.1186/s11671-016-1640-1

Dong A, Jiao Y, Milliron DJ (2013) Electronically coupled nanocrystal superlattice films by in situ ligand exchange at the liquid-air interface. ACS Nano 7:10978–10984. doi:10.1021/nn404566b

Dong A, Ye X, Chen J, Kang Y, Gordon T, Kikkawa JM, Murray CB (2011) A generalized ligand-exchange strategy enabling sequential surface functionalization of colloidal nanocrystals. J Am Chem Soc 133:998–1006. doi:10.1021/ja108948z

Eggenhuisen TM et al (2015) High efficiency, fully inkjet printed organic solar cells with freedom of design. J Mater Chem A 3:7255–7262. doi:10.1039/c5ta00540j

Fei F et al (2015) A printed aluminum cathode with low sintering temperature for organic light-emitting diodes. RSC Adv 5:608–611. doi:10.1039/c4ra09197c

Frenken JW, van der Veen JF (1985) Observation of surface melting. Phys Rev Lett 54:134–137. doi:10.1103/PhysRevLett.54.134

Friend RH et al (1999) Electroluminescence in conjugated polymers. Nature 397:121–128

Galagan Y et al (2014) Solution processing of back electrodes for organic solar cells with inverted architecture. Sol Energy Mater Sol Cells 130:163–169. doi:10.1016/j.solmat.2014.07.007

Greer JR, Street RA (2007) Mechanical characterization of solution-derived nanoparticle silver ink thin films. J Appl Phys 101:103529. doi:10.1063/1.2735404

Grouchko M, Kamyshny A, Mihailescu CF, Anghel DF, Magdassi S (2011) Conductive inks with a “built-in” mechanism that enables sintering at room temperature. ACS Nano 5:3354–3359. doi:10.1021/nn2005848

Gu G, Forrest SR (1998) Design of flat-panel displays based on organic light-emitting devices. IEEE J Sel Top Quant Electron 4:83–99. doi:10.1109/2944.669473

Gupta R, Walia S, Hosel M, Jensen J, Angmo D, Krebs FC, Kulkarni GU (2014) Solution processed large area fabrication of Ag patterns as electrodes for flexible heaters, electrochromics and organic solar cells. J Mater Chem A 2:10930–10937. doi:10.1039/c4ta00301b

Hosel M, Søndergaard R, Angmo D, Krebs FC (2013) Comparison of fast roll-to-roll flexographic, inkjet, flatbed, and rotary screen printing of metal back electrodes for polymer solar cells. Adv Eng Mater 15:995–1001. doi:10.1002/adem.201300011

Huang D, Liao F, Molesa S, Redinger D, Subramanian V (2003) Plastic-compatible low resistance printable gold nanoparticle conductors for flexible electronics. J Electrochem Soc 150:G412–G417. doi:10.1149/1.1582466

Jo Y et al (2014) Extremely flexible, printable Ag conductive features on PET and paper substrates via continuous millisecond photonic sintering in a large area. J Mater Chem C 2:9746–9753. doi:10.1039/c4tc01422g

Jung I, Jo YH, Kim I, Lee HM (2011) A simple process for synthesis of Ag nanoparticles and sintering of conductive ink for use in printed electronics. J Electron Mater 41:115–121. doi:10.1007/s11664-011-1761-3

Jung I, Shin K, Kim NR, Lee HM (2013) Synthesis of low-temperature-processable and highly conductive Ag ink by a simple ligand modification: the role of adsorption energy. J Mater Chem C 1:1855–1862. doi:10.1039/c2tc00450j

Kim D, Moon J (2005) Highly conductive ink jet printed films of nanosilver particles for printable electronics. Electrochem Solid-State Lett 8:J30–J33. doi:10.1149/1.2073670

Kim H-S, Dhage SR, Shim D-E, Hahn HT (2009) Intense pulsed light sintering of copper nanoink for printed electronics. Appl Phys A 97:791–798. doi:10.1007/s00339-009-5360-6

Ko SH, Pan H, Grigoropoulos CP, Luscombe CK, Fréchet JMJ, Poulikakos D (2007a) Air stable high resolution organic transistors by selective laser sintering of ink-jet printed metal nanoparticles. Appl Phys Lett 90:141103. doi:10.1063/1.2719162

Ko SH, Pan H, Grigoropoulos CP, Luscombe CK, Fréchet JMJ, Poulikakos D (2007b) All-inkjet-printed flexible electronics fabrication on a polymer substrate by low-temperature high-resolution selective laser sintering of metal nanoparticles. Nanotechnology 18:345202

Krebs FC, Søndergaard R, Jørgensen M (2011) Printed metal back electrodes for R2R fabricated polymer solar cells studied using the LBIC technique. Sol Energy Mater Sol Cells 95:1348–1353. doi:10.1016/j.solmat.2010.11.007

Larmagnac A, Eggenberger S, Janossy H, Voros J (2014) Stretchable electronics based on Ag-PDMS composites. Sci Rep 4:7254. doi:10.1038/srep07254

Layani M, Grouchko M, Shemesh S, Magdassi S (2012) Conductive patterns on plastic substrates by sequential inkjet printing of silver nanoparticles and electrolyte sintering solutions. J Mater Chem 22:14349. doi:10.1039/c2jm32789a

Layani M, Magdassi S (2011) Flexible transparent conductive coatings by combining self-assembly with sintering of silver nanoparticles performed at room temperature. J Mater Chem 21:15378. doi:10.1039/c1jm13174e

Lee SK et al (2011) Stretchable graphene transistors with printed dielectrics and gate electrodes. Nano Lett 11:4642–4646. doi:10.1021/nl202134z

Lewis LJ, Jensen P, Barrat J-L (1997) Melting, freezing, and coalescence of gold nanoclusters. Phys Rev B 56:2248–2257

Li W, Dittrich T, Jackel F, Feldmann J (2014) Optical and electronic properties of pyrite nanocrystal thin films: the role of ligands. Small 10:1194–1201. doi:10.1002/smll.201302333

Magdassi S, Grouchko M, Berezin O, Kamyshny A (2010) Triggering the sintering of silver nanoparticles at room temperature. ACS Nano 4:1943–1948. doi:10.1021/nn901868t

Moon KS, Dong H, Maric R, Pothukuchi S, Hunt A, Li Y, Wong CP (2005) Thermal behavior of silver nanoparticles for low-temperature interconnect applications. J Electron Mater 34:168–175. doi:10.1007/s11664-005-0229-8

Nobusa Y, Yomogida Y, Matsuzaki S, Yanagi K, Kataura H, Takenobu T (2011) Inkjet printing of single-walled carbon nanotube thin-film transistors patterned by surface modification. Appl Phys Lett 99:183106. doi:10.1063/1.3657502

Perelaer J, de Gans BJ, Schubert US (2006) Ink-jet printing and microwave sintering of conductive silver tracks. Adv Mater 18:2101–2104. doi:10.1002/adma.200502422

Perelaer J, de Laat AWM, Hendriks CE, Schubert US (2008) Inkjet-printed silver tracks: low temperature curing and thermal stability investigation. J Mater Chem 18:3209–3215. doi:10.1039/b720032c

Polavarapu L, Manga KK, Cao HD, Loh KP, Xu QH (2011) Preparation of conductive silver films at mild temperatures for printable organic electronics. Chem Mater 23:3273–3276. doi:10.1021/cm200471s

Richardson JJ, Bjornmalm M, Caruso F (2015) Multilayer assembly. Technology-driven layer-by-layer assembly of nanofilms. Science 348:aaa2491. doi:10.1126/science.aaa2491

Russo A, Ahn BY, Adams JJ, Duoss EB, Bernhard JT, Lewis JA (2011) Pen-on-paper flexible electronics. Adv Mater 23:3426–3430. doi:10.1002/adma.201101328

Seo M, Kim JS, Lee JG, Kim SB, Koo SM (2016) The effect of silver particle size and organic stabilizers on the conductivity of silver particulate films in thermal sintering processes. Thin Solid Films 616:366–374. doi:10.1016/j.tsf.2016.08.060

Sivaramakrishnan S, Chia PJ, Yeo YC, Chua LL, Ho PK (2007) Controlled insulator-to-metal transformation in printable polymer composites with nanometal clusters. Nat Mater 6:149–155. doi:10.1038/nmat1806

Vo DQ, Kim EJ, Kim S (2009) Surface modification of hydrophobic nanocrystals using short-chain carboxylic acids. J Colloid Interface Sci 337:75–80. doi:10.1016/j.jcis.2009.04.078

Wakuda D, Hatamura M, Suganuma K (2007) Novel method for room temperature sintering of Ag nanoparticle paste in air. Chem Phys Lett 441:305–308. doi:10.1016/j.cplett.2007.05.033

Wakuda D, Keun-Soo K, Suganuma K (2009) Room-temperature sintering process of Ag nanoparticle paste. IEEE Trans Components Packag Technol 32:627–632. doi:10.1109/tcapt.2009.2015874

Wu CJ, Sheng YJ, Tsao HK (2016) Copper conductive lines on flexible substrates fabricated at room temperature. J Mater Chem C 4:3274–3280. doi:10.1039/c6tc00234j

Wu NQ, Fu L, Su M, Aslam M, Wong KC, Dravid VP (2004) Interaction of fatty acid monolayers with cobalt nanoparticles. Nano Lett 4:383–386. doi:10.1021/nl1035139x

Xu ZC, Shen CM, Hou YL, Gao HJ, Sun SS (2009) Oleylamine as both reducing agent and stabilizer in a facile synthesis of magnetite nanoparticles. Chem Mater 21:1778–1780. doi:10.1021/cm802978z

Zeng WJ, Wu HB, Zhang C, Huang F, Peng JB, Yang W, Cao Y (2007) Polymer light-emitting diodes with cathodes printed from conducting Ag paste. Adv Mater 19:810–814. doi:10.1002/adma.200602567

Zhang J, Fang J (2009) A general strategy for preparation of Pt 3d-transition metal (Co, Fe, Ni) nanocubes. J Am Chem Soc 131:18543–18547. doi:10.1021/ja908245r

Zhang L, He R, Gu H-C (2006) Oleic acid coating on the monodisperse magnetite nanoparticles. Appl Surf Sci 253:2611–2617. doi:10.1016/j.apsusc.2006.05.023

Zhang Z, Zhu W (2015) Controllable synthesis and sintering of silver nanoparticles for inkjet-printed flexible electronics. J Alloys Compd 649:687–693. doi:10.1016/j.jallcom.2015.07.195

Zheng H et al (2013) All-solution processed polymer light-emitting diode displays. Nat Commun:4. doi:10.1038/ncomms2971

Acknowledgements

This work was supported by the National Research Foundation (NRF) of Korea grant funded by the Ministry of Science, ICT and Future Planning (MSIP) (No. NRF-2015R1A5A1037627) and by the NRF of Korea grant funded by the Korea government (MEST) (No. 2011-0028612).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(DOCX 1518 kb)

Rights and permissions

About this article

Cite this article

Lee, Y.J., Kim, N.R., Lee, C. et al. Uniform thin film electrode made of low-temperature-sinterable silver nanoparticles: optimized extent of ligand exchange from oleylamine to acrylic acid. J Nanopart Res 19, 32 (2017). https://doi.org/10.1007/s11051-016-3720-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11051-016-3720-7