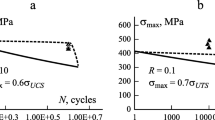

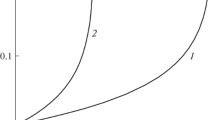

An analysis of correlation between the static strength and fatigue life of a layered glass-fiber composite is carried out by using the Markov chain theory. The parameters of the Markov model of fatigue life are connected with parameters of the local static strength of components of a composite. The distribution of the static strength of the composite and the possibilities of description of its fatigue life and static strength by using Markov chains is investigated on the basis of data obtained from static and fatigue tests of specimens made of a composite manufactured from a unidirectional UDO® glass fabric of type E and a polyether resin (HAVELpol.2). A numerical example is presented.

Similar content being viewed by others

References

B. Kuttkat, “Leichtgewichte sind gefragt,” Maschinenmarkt, 113, No. 29, 102-107 (2007).

L. J. Broutman and S. Sahu, “A new theory to predict cumulative fatigue damage in glass-fabric-reinforced plastics,” Composite Materials: Testing and Design, ASTM STP, 497, 170-188 (1972).

P. C. Chou and R. Croman, “Degradation and sudden death models of fatigue of graphite/epoxy composites,” Composite Materials: Testing and Design, ASTM STP, 674, 431-54 (1979).

M. S. Found and M. Quaresimin, “Two-stage fatigue loading of woven carbon-fiber-reinforced laminates,” Fatigue Fract. Eng. Mater. Struct., 2, 17-26 (2003).

R. Chatys, I. Chatys, and M. Kleinhofs, “Modelling the effect of service conditions on the strength of fiber glass-reinforced polymer-matrix composite materials,” in: XI Seminar “Plastics in Machine Design,” Kraków, Poland, (2006), pp.123-126.

T. P. Philippidis and V. A. Passipoularidis, “Residual strength after fatigue in composites: theory vs. experiment,” Inter. J. Fatigue, 29, 2104-2116 (2007).

Yu. Paramonov and J. Andersons, “A family of weakest link models for fiber strength distribution,” Composites: Pt A38, 1227-1233 (2007).

Yu. Paramonov, R. Chatys, J. Andersons, and M. Kleinhofs, “Markov model оf fatigue оf a composite material with the Poisson process оf defect initiation,” Mech. Compos. Mater., 48, No. 2, 217-228 (2012).

Yu. M. Paramonov, M. A. Kleinhof, and A. Yu. Paramonova, “Markov model of connection between the distribution of static strength and the fatigue life of a fibrous composite,” Mech. Compos. Mater., 42, No. 5, 431-442 (2006).

Yu. Paramonov, R. Chatys, J. Andersons, and M. Kleinhofs, “Poisson process of defect initiation in fatigue of a composite material,” Int. Conf. “RelStat’2011,” Riga, Latvia, 20-21 October (2011).

M. M. Shokrieh and F. A. Taheri-Behrooz, “Unified fatigue life model based on the energy method,” Compos. Struct., 75, 444-450 (2006).

Catalog “Composites HAVEL”.

C. R. Barker and M. Mazurkiewicz, “Evolution of on abrasive clearing system,” in: VI Int. Symp. Jet Cutting Technology. Paper K1, Surrey, UK (1982), pp. 429-446.

A. W. Member and J. A. Koller, “Comparison between grit-blasting (AB), water jetting (UHP) and ultra-high pressure abrasive blasting (UHPAB) for steel surface preparation. Manuscript,” in: XVII Int. Conf. Water Jetting “Advances and Future Needs”, Mainz, Germany (2004), pp. 147-156.

E. Wantuch, A. Karpiński, and R. Kot, “Efektywno ść przecinania stali wysokociśnieniowym strumieniem wodno-ś ciernym z zastosowaniem różnych ścierniw,” XXIII Naukowa Szkoła Obróbki Ściernej, Rzeszów/Myczkowce (2000), pp. 536-544.

R. Chatys, “Modeling of the effect of laser treatment and machining on the strength and quality of composite materials,” Int. Conf. 13-17 February 2006, Moscov, Russia.

R. Chatys, “Modeling of mechanical properties with the increasing demands in the range of qualities and repeatability of polymer composite elements,” in: Public. Monograph “Polymers and Constructional Composites,” Gliwice, Poland (2008), pp. 36-47.

Report within the framework of the Project ESF Нр. 2009/0209/1DP/1.1.1.2.0/09/APIA/VIAA/114 “Fatigue Experimental — Finish Program,” Riga (2010).

ASTM D638 — Standard Test Method for Tensile Properties of Plastics.

H. T. Hahn and R. Y. Kim, “Proof testing of composite materials,” J. Compos. Mater., 9, 297-311 (1975).

Acknowledgments

This study was supported by the Project ESF NO: 2009/0209/1DP/1.1.1.2.0/09/APIA/VIAA/114.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Mekhanika Kompozitnykh Materialov, Vol. 48, No. 6, pp. 911-922 , November-December, 2012.

Rights and permissions

About this article

Cite this article

Chatys, R. Investigation of the effect of distribution of the static strength on the fatigue failure of a layered composite by using the markov chain theory. Mech Compos Mater 48, 629–638 (2013). https://doi.org/10.1007/s11029-013-9307-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11029-013-9307-9