Abstract

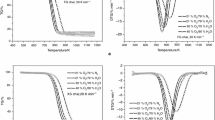

The paper presents a comparison of combustion processes of two- and three-component fuel mixtures based on char and two brown coals with different technical and elemental composition, applying thermogravimetric analysis in an air flow, at a heating rate of 20 °C min−1. From the mass loss, mass change rate (TG/DTG) curves showing the combustion process of the fuels, the following characteristics were determined: ignition temperature, burnout temperature and combustion index. Using differential scanning calorimetry (DSC) curves, endothermic and exothermic effects as well as maximum heat flux intensities during fuel combustion were determined. Based on the results of these studies, a linear dependence of the combustion index on the combustion heat of two- and three-component fuels was established for the first time. An increase in the calorific value of the fuel mixture by more than 7% affects a decrease in the combustion index to 100%. A maximum percentage of char not exceeding 20–30% added to two- and three-component fuel mixtures, exceeding which will entail a reduction in the combustion characteristics of the mixtures has been established. It is noted that three-component fuel mixtures are promising for practical application, as the addition of two high-reaction and high-energy fuel components to the base fuel has a positive effect on increasing the energy characteristics of the mixture and reducing the duration of the induction period.

Similar content being viewed by others

Abbreviations

- A ad :

-

Ash (mass%)

- C ad, H ad, N ad, O ad, S ad :

-

Fraction of carbon, hydrogen, nitrogen, oxygen and sulfur in the coal converted to an air-dried basis (%)

- FC ad :

-

Fixed carbon (mass%)

- HHV :

-

Higher heating value (MJ kg–1)

- M ad :

-

Total moisture based on the air-dried basis (mass%)

- Q peak1- 2 :

-

Maximum heat flux intensity (W g–1)

- R max :

-

Maximum mass loss rate (mass% min–1)

- R mean :

-

Average mass loss rate (from ignition to burnout) (mass% min–1)

- S :

-

Combustion index (10–6/min–2 °C–3)

- T b :

-

Burnout temperature (°C)

- T i :

-

Ignition temperature (°C)

- T peak1-2 :

-

Temperature of the maximum heat flux intensity (°C)

- V ad :

-

Volatile matter based on the dry, ash-free basis (mass%)

References

Stevanovic VD, Petrovic MM, Wala T, Milivojevic S, Ilic M, Muszynski S. Efficiency and power upgrade at the aged lignite-fired power plant by flue gas waste heat utilization: High pressure versus low pressure economizer installation. Energy. 2019;187: 115980. https://doi.org/10.1016/j.energy.2019.115980.

Yang W, Pudasainee D, Gupta R, Li W, Wang B, Sun L. An overview of inorganic particulate matter emission from coal/biomass/MSW combustion: Sampling and measurement, formation, distribution, inorganic composition and influencing factors. Fuel Process Technol. 2021;213: 106657. https://doi.org/10.1016/j.fuproc.2020.106657.

Zhuikov AV, Kulagin VA, Baranova MP, Glushkov DO. Boiler startup under conditions of convective heating of the highly reactive coal dust. Therm Eng. 2016;63(12):870–5. https://doi.org/10.1134/S0040601516120107.

Maaten B, Konist A, Siirde A. High-speed thermogravimetric analysis of the combustion of wood and Ca-rich fuel. J Therm Anal Calorim. 2019;138:2807–11. https://doi.org/10.1007/s10973-019-08785-6.

Niu S, Chen M, Li Y, Song J. Co-combustion characteristics of municipal sewage sludge and bituminous coal. Therm Anal Calorim. 2018;131:1821–34. https://doi.org/10.1007/s10973-017-6716-3.

Namkung H, Lee Y-J, Park J-H, Song G-S, Choi JW, Choi Y-C, Park S-J, Kim J-G. Blending effect of sewage sludge and woody biomass into coal on combustion and ash agglomeration behavior. Fuel. 2018;225:266–76. https://doi.org/10.1016/j.fuel.2018.03.109.

Wang H, Zhang J, Wang G, Xu R, Zhang P, Liu S, Song T. Characteristics and kinetic analysis of co-combustion of brown coal and anthracite. J Therm Anal Calorim. 2016;126:447–54. https://doi.org/10.1007/s10973-016-5557-9.

Wang C, Wang C, Jia X, Zhao L, Wang P. NO formation characteristics and fuel-nitrogen transformation mechanism during co-firing of low-volatile carbon-based solid fuels with bituminous coal. Fuel. 2021;291: 120134. https://doi.org/10.1016/j.fuel.2021.120134.

Guan J, Yu Q, Sun R, Shen T, Wang M, Yan Y, Song X. Experimental investigation for co-combustion characteristics of semi-coke and bituminous coal in a 3 MWth tangential combustion facility. J Therm Sci. 2020;29:1655–62. https://doi.org/10.1007/s11630-020-1187-4.

Qi H, Sun R, Peng J, Meng X, Cao Z, Wang Z, Ren X, Yuan M, Zhang L, Ding S. Experimental investigation on the ignition and combustion characteristics of pyrolyzed char and bituminous coal blends. Fuel. 2020;281: 118732. https://doi.org/10.1016/j.fuel.2020.118732.

Hu L, Zhang Y, Chen D, Fang J, Zhang M, Wu Y, Zhang H, Li Z, Lyu J. Experimental study on the combustion and NOx emission characteristics of a bituminous coal blended with semi-coke. Appl Therm Eng. 2019;160: 113993. https://doi.org/10.1016/j.applthermaleng.2019.113993.

Zhang J, Jia X, Wang C, Zhao N, Wang P, Che D. Experimental investigation on combustion and NO formation characteristics of semi-coke and bituminous coal blends. Fuel. 2019;247:87–96. https://doi.org/10.1016/j.fuel.2019.03.045.

Zhao R, Qin J, Chen T, Wu J. TG-FTIR study on co-combustion of bituminous coal semicoke and lignite. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10405-7.

Wang C, Wang C, Jia X, Gao X, Wang P, Feng Q, Che D. Experimental investigation on combustion characteristics and kinetics during Co-Firing bituminous coal with ultra-low volatile carbon-based solid fuels. J Energy Inst. 2021;95:87–100. https://doi.org/10.1016/j.joei.2021.01.005.

Yao H, He B, Ding G, Tong W, Kuang Y. Thermogravimetric analyses of oxy-fuel co-combustion of semi-coke and bituminous coal. Appl Therm Eng. 2019;156:708–21. https://doi.org/10.1016/j.applthermaleng.2019.04.115.

Zheng S, Hu Y, Wang Z, Cheng X. Experimental investigation on ignition and burnout characteristics of semi-coke and bituminous coal blends. J Energy Inst. 2020;93:1373–81. https://doi.org/10.1016/j.joei.2019.12.007.

Glushkov DO, Matiushenko AI, Nurpeiis AE, Zhuikov AV. An experimental investigation into the fuel oil-free start-up of a coal-fired boiler by the main solid fossil fuel with additives of brown coal, biomass and charcoal for ignition enhancement. Fuel Process Technol. 2021;223: 106986. https://doi.org/10.1016/j.fuproc.2021.106986.

Glushkov DO, Kuznetsov GV, Chebochakova DA, Lyakhovskaya OE, Shlegel NE, Anufriev IS, Shadrin EY. Experimental study of coal dust ignition characteristics at oil-free start-up of coal-fired boilers. Appl Therm Eng. 2018;142:371–9. https://doi.org/10.1016/j.applthermaleng.2018.07.010.

ISO 11722:1999, Solid mineral fuels – Hard coal – Determination of moisture in the general analysis test sample by drying in nitrogen.

ISO 1171:2010, Solid mineral fuel – Determination of ash.

ISO 562:2010, Hard coal and coke – Determination of volatile matter.

ISO 1928:2009, Solid mineral fuels – Determination of gross calorific value by the bomb calorimetric method and calculation of net calorific value.

ASTM D5373–14e1, Standard Test Methods for Determination of Carbon, Hydrogen and Nitrogen in Analysis Samples of Coal and Carbon in Analysis Samples of Coal and Coke, ASTM International, West Conshohocken, PA, 2014.

Oladejo JM, Adegbite S, Pang CH, Liu H, Parvez AM, Wu T. A novel index for the study of synergistic effects during the co-processing of coal and biomass. Appl Energy. 2017;188:215–25. https://doi.org/10.1016/j.apenergy.2016.12.005.

Moon C, Sung Y, Ahn S, Kim T, Choi G, Kim D. Effect of blending ratio on combustion performance in blends of biomass and coals of different ranks. Exp Therm Fluid Sci. 2013;47:232–40. https://doi.org/10.1016/j.expthermflusci.2013.01.019.

Seggiani M, Vitolo S, Pastorelli M, Ghetti P. Combustion reactivity of different oil-fired fly ashes as received and leached. Fuel. 2007;86:1885–91. https://doi.org/10.1016/j.fuel.2006.12.010.

Liu H, Gong S, Jia C, Wang Q. TG-FTIR analysis of co-combustion characteristics of oil shale semi-coke and corn straw. J Therm Anal Calorim. 2017;127:2531–44. https://doi.org/10.1007/s10973-016-5739-5.

Liu Z, Quek A, Kent Hoekman S, Srinivasan MP, Balasubramanian R. Thermogravimetric investigation of hydrochar-lignite co-combustion. Bioresour Technol. 2013;133:639–40. https://doi.org/10.1016/j.biortech.2012.06.063.

Wang G, Zhang J, Shao J, Liu Z, Zhang G, Xu T, Guo J, Wang H, Xu R, Lin H. Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers Manag. 2016;124:414–26. https://doi.org/10.1016/j.enconman.2016.07.045.

Zhang Y, Guo Y, Cheng F, Yan K, Cao Y. Investigation of combustion characteristics and kinetics of coal gangue with different feedstock properties by thermogravimetric analysis. Thermochim Acta. 2015;614:137–48. https://doi.org/10.1016/j.tca.2015.06.018.

Liu X, Chen M, Wei Y. Assessment on oxygen enriched air co-combustion performance of biomass/bituminous coal. Renew Energy. 2016;92:428–36. https://doi.org/10.1016/j.renene.2016.02.035.

Sarkar P, Sahu SG, Mukherjee A, Kumar M, Adak AK, Chakraborty N, Biswas S. Co-combustion studies for potential application of sawdust or its low temperature char as co-fuel with coal. Appl Therm Eng. 2014;63:616–23. https://doi.org/10.1016/j.applthermaleng.2013.11.069.

Deng S, Tan H, Wei B, Wang X, Yang F, Xiong X. Investigation on combustion performance and ash fusion characteristics of Zhundong coal co-combustion with coal gangue. Fuel. 2021;294: 120555. https://doi.org/10.1016/j.fuel.2021.120555.

Zhang K, Zhang K, Cao Y, Pan WP. Co-combustion characteristics and blending optimization of tobacco stem and high-sulfur bituminous coal based on thermogravimetric and mass spectrometry analyses. Bioresour Technol. 2013;131:325–32. https://doi.org/10.1016/j.biortech.2012.12.163.

Li XG, Lv Y, Ma BG, Jian SW, Tan HB. Thermogravimetric investigation on co-combustion characteristics of tobacco residue and high-ash anthracite coal. Bioresour Technol. 2011;102:9783–7. https://doi.org/10.1016/j.biortech.2011.07.117.

Jiang XM, Cui ZG, Han XX, Yu HL. Thermogravimetric investigation on combustion characteristics of oil shale and high sulphur coal mixture. J Therm Anal Calorim. 2006;85:761–4. https://doi.org/10.1007/s10973-005-7151-4.

Vamvuka D, Loukakou E, Sfakiotakis S, Petrakis E. The impact of a combined pre-treatment on the combustion performance of various biomass wastes and their blends with lignite. Thermochim Acta. 2020;688: 178599. https://doi.org/10.1016/j.tca.2020.178599.

Chen L, Wen C, Wang W, Liu T, Liu E, Liu H, Li Z. Combustion behaviour of biochars thermally pretreated via torrefaction, slow pyrolysis, or hydrothermal carbonisation and co-fired with pulverised coal. Renew Energy. 2020;161:867–77. https://doi.org/10.1016/j.renene.2020.06.148.

Wang C, Wang F, Yang Q, Liang R. Thermogravimetric studies of the behavior of wheat straw with added coal during combustion. Biomass Bioenergy. 2009;33:50–6. https://doi.org/10.1016/j.biombioe.2008.04.013.

Li XG, Ma BG, Xu L, Hu Z-W, Wang X-G. Thermogravimetric analysis of the co-combustion of the blends with high ash coal and waste tyres. Thermochim Acta. 2006;441:79–83. https://doi.org/10.1016/j.tca.2005.11.044.

Lu J-J, Chen W-H. Investigation on the ignition and burnout temperatures of bamboo and sugarcane bagasse by thermogravimetric analysis. Appl Energy. 2015;160:49–57. https://doi.org/10.1016/j.apenergy.2015.09.026.

Niu SL, Han KH, Lu CM. Characteristic of coal combustion in oxygen/carbon dioxide atmosphere and nitric oxide release during this process. Energy Convers Manag. 2011;52:532–7. https://doi.org/10.1016/j.enconman.2010.07.028.

Bala-Litwiniak A, Zajemska M. Computational and experimental study of pine and sunflower husk pellet combustion and co-combustion with oats in domestic boiler. Renew Energy. 2020;162:151–9. https://doi.org/10.1016/j.renene.2020.07.139.

Ding G, He B, Yao H, Cao Y, Su L, Duan Z. Co-combustion behaviors of municipal solid waste and low-rank coal semi-coke in air or oxygen/carbon dioxide atmospheres. J Therm Anal Calorim. 2021;143:619–35. https://doi.org/10.1007/s10973-019-09170-z.

Acknowledgements

This research was supported by the Russian Science Foundation [grant number 22-23-00040, https://rscf.ru/en/project/22-23-00040/].

Author information

Authors and Affiliations

Contributions

AV Zhuikov: Resources, Investigation, Writing - original draft, Data curation, Validation. DO Glushkov: Funding acquisition, Project administration, Supervision, Conceptualization. PN Kuznetsov: Data curation, Validation, Writing - original draft. II Grishina: Investigation, Writing - original draft. AS Samoilo: Investigation, Software, Visualization.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhuikov, A.V., Glushkov, D.O., Kuznetsov, P.N. et al. Ignition of two-component and three-component fuel mixtures based on brown coal and char under slow heating conditions. J Therm Anal Calorim 147, 11965–11976 (2022). https://doi.org/10.1007/s10973-022-11406-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-022-11406-4