Abstract

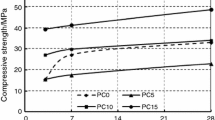

The effect of fired drinking water sludge (FDWS) as a mineral admixture on the physico-mechanical properties and the fire resistance of pozzolanic cement pastes has been investigated. Five blends of ordinary Portland cement, blast-furnace slag (GBFS) and FDWS were prepared. The Portland cement was fixed to 70 mass%, while granulated slag was replaced by 0, 3, 6, 9 and 12 mass% of fired sludge. The phase composition was identified using X-ray diffraction, thermal gravimetric analysis and differential scanning calorimetry. The results have shown an increase in the required water of standard consistency and elongation of setting times with increasing the fired sludge content. The bulk density has decreased with increasing the sludge content, while the compressive strength was enhanced at later ages for 3 and 6 mass% FDWS substitution. In addition, the specimen that contains 9 mass% FDWS gave the best firing resistance at high temperature, whereas Portland cement paste has been completely deteriorated at 800 °C.

Similar content being viewed by others

References

Kosmatka SH, Panarese WC. Design and control of concrete mixtures. Skoki, II, USA: Portland Cement Association; 1988.

Ramachandran VS. Concrete admixtures handbook of properties, science and technology. USA: Noyes Publications; 1984.

Kar A, Ray I, Unnikrishnan A, Davalos JF. Estimation of C–S–H and calcium hydroxide for cement pastes containing slag and silica fume. Constr Build Mater. 2012;30:505–15.

Hosam El-Din HS, Rashad AM, El-Sabbagh BA. Durability and strength evaluation of high-performance concrete in marine structure. Constr Build Mater. 2010;24:878–84.

Shi C, Qian J. High performance cementing materials from industrial slags: a review. Resour Conserv Recycl. 2000;29:195–207.

Rodríguez NH, Ramírez SM, Varela MTB, et al. Re-use of drinking water treatment plant (DWTP) sludge: characterization and technological behavior of cement mortars with atomized sludge additions. Cem Concr Res. 2010;40:778–86.

El-Didamony H, Amer AA, Mohammed MS. Hydration and mechanical properties of cement/sludge/anhydrite gypsum system. Adv Cem Res. 2014;26:248–55.

Amer AA, Mohammed MS. Pozzolanic activity evaluation of the fired drinking water treatment sludge. IJERT. 2014;3:1488–501.

Pane I, Hansen W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem Concr Res. 2005;35:1155–64.

Haddad RH, Shannis LG. Post-fire behavior of bond between high strength pozzolanic concrete and reinforcing steel. Constr Build Mater. 2004;18(6):425–35.

Heikal M, Ali AI, Ismail MN, Ibrahim ASNS. Behavior of composite cement pastes containing silica nano-particles at elevated temperature. Constr Build Mater. 2014;70:339–50.

ASTM designation: C191. Standard test method for normal consistency and setting time of hydraulic cement. Annual Book of ASTM Standard;2008.

ASTM Designation: C150. Standard Test Methods for Compressive Strength of Hydraulic Cements; 2007.

Mohammed MS, Ahmed AE-SI, Osman RM. Microcrystalline cellulose as a reinforcement agent to cement pastes. Pigm Resin Technol. 2014;43:104–10.

Mohammed MS, Ahmed AE-SI, Osman RM, Khattab I. Combinations of organic and inorganic wastes for brick production. Polym Compos. 2014;35:174–9.

El-Didamony H, El-Rahman EA, Osman RM. Fire resistance of fired clay bricks–fly ash composite cement pastes. Ceram Int. 2012;38:201–9.

Aziz MAA-E, Aleem SAE, Heikal M. Physico-chemical and mechanical characteristics of pozzolanic cement pastes and mortars hydrated at different curing temperatures. Constr Build Mater. 2012;26:310–6.

Hekal EE, Abo-El-Enein SA, El-Korashy SA, Megahed GM, El-Sayed TM. Utilization of electric arc furnace dust as an admixture to Portland cement pastes. J Therm Anal Calorim. 2013;114:613–9.

Björnström J, Martinelli A, Matic A, Börjesson L, Panas I. Accelerating effects of colloidal nano-silica for beneficial calcium–silicate–hydrate formation in cement. Chem Phys Lett. 2004;392:242–8.

Ramachandran VS, Paroli RM, Beaudoin JJ, Delgado AH. Handbook of thermal analysis of construction materials. New York, USA: Noys Public; 2000.

Rashad AM. An exploratory study on sodium sulphate-activated slag blended with Portland cement under the effect of thermal loads. J Therm Anal Calorim. 2015;119:1535–45.

Mendoza O, Tobón JI. An alternative thermal method for identification of pozzolanic activity in Ca(OH)2/pozzolan pastes. J Therm Anal Calorim. 2013;114:589–96.

Liu S, Xie G, Wang S. Effect of curing temperature on hydration properties of waste glass powder in cement-based materials. J Therm Anal Calorim. 2015;119:47–55.

Sha W, O’Neill EA, Guo Z. Differential scanning calorimetry study of ordinary Portland cement. Cem Concr Res. 1999;29:1487–9.

Mohammed MS. The Pozzolanic Activity of Air-cooled Slag. MSc thesis: Zagazig University, Zagazig, Egypt. 2000.

Morsy MS, Al-Salloum Y, Almusallam T, Abbas H. Effect of nano-metakaolin addition on the hydration characteristics of fly ash blended cement mortar. J Therm Anal Calorim. 2014;116:845–52.

Oriol M, Pera J. Pozzolanic activity of metakaolin under microwave treatment. Cem Concr Res. 1995;25:265–70.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

El-Didamony, H., Mohammed, M.S. & Osman, R.M. Effect of substitution of blast-furnace slag by fired drinking water sludge on the properties of pozzolanic cement pastes. J Therm Anal Calorim 122, 81–88 (2015). https://doi.org/10.1007/s10973-015-4691-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4691-0