Abstract

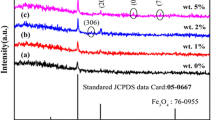

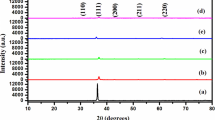

Undoped and Co doped Cu2O (Cu2−xCoxO; x = 0, 1, 2, 5 and 10) thin films were deposited onto glass substrates using successive ionic layer adsorption and reaction technique. The variation in the concentration of Co shows significant impact on the film properties, where as doped with 10 wt% of Co exhibited major property improvements when compared with other films. The prepared films were characterized for their structural, morphological, optical and magnetic properties. X-ray diffraction analysis of the films revealed the crystalline growth of Cu2−xCoxO films. The substitution of Cu2+ by Co2+ ions has led to a single phase cubic structure highly oriented along (111) plane. Optical studies (photoluminescence and UV–vis–NIR) of the films exhibit the quality of the films with the increase of dopant. The stretching vibrations of Cu–O and O–Cu–O have been confirmed by Fourier transform infrared spectroscopy. The morphological study done by a field emission scanning electron microscope has shown as increase of particle size with increase in the dopant concentration. High resolution of transition electron microscope and particle analyzer verified the nano-size and shape of the films. The presence of copper in the structure of thin film was confirmed by energy dispersive X-ray spectrometer. Magnetic measurements showed that undoped and minimum doped (1 and 2 wt%) films exhibit diamagnetic behavior and at the maximum (10 wt%) Co doping level, the films exhibit ferromagnetic properties. Current verses voltage studies showed the ohmic nature of the films.

Similar content being viewed by others

References

K. Mageshwari, R. Sathyamoorthy, Mater. Sci. Semicond. Process. 16, 337 (2013)

S.L. Mammah, F.E. Opara, V.B. Omubo-Pepple, J.E.-E. Ntibi, S.C. Ezugwu, F.I. Ezema, Nat. Sci. 5, 389 (2013)

L.-C. Chen, Mater. Sci. Semicond. Process. 16, 1172 (2013)

L. Zhang, L. McMillon, J. McNatt, Sol. Energy Mater. Sol. Cells 108, 230 (2013)

F. Bayansal, T. TasKoPru, B. Sahin, H.A. Cetinkara, Miner. Met. Mater. Soc. ASM. Int. (2014). doi:10.1007/s11661-014-2306-1

G. Fan, F. Li, Chem. Eng. J. 167, 388 (2011)

H.S. Lim, D. Kwak, D.Y. Lee, K. Cho, J. Am. Chem. Soc. 129, 4128 (2007)

P.A. Praveenjanantha, L.N.L. Perera, K.M.D.C. Jayathilaka, J.K.D.S. Jayanetti, D.P. Dissanayaka, W.P. Siripala, Process. Tech. Sess. 25, 70 (2009)

V. Georgieva, M. Ristov, Sol. Energy Mater. Sol. Cells 73, 67 (2002)

K. Han, M. Tao, Sol. Energy Mater. Sol. Cells 93, 153 (2009)

X.P. Gao, J.L. Bao, G.L. Pan, H.Y. Zhu, P.X. Huang, F. Wu, D.Y. Song, J. Phys. Chem. B 108, 5547 (2004)

J.M.D. Coey, M. Venkatesan, C.B. Fitzgerald, Nat. Mater. 4, 173 (2005)

Y. Ghayeb, M.M. Momeni, A. Mozafari, J. Mater. Sci. Mater. Electron. (2016). doi:10.1007/s10854-016-5321-8

M.M. Momeni, Indian J. Chem. 55A, 686 (2016)

M.M. Momeni, I. Ahadzadeh, Mater. Res. Innov. 20, 44 (2016)

M.M. Momeni, Y. Ghayeb, Z. Ghonchegi, Ceram. Int. 41, 8735 (2015)

M.M. Momeni, M. Mirhosseini, M. Chavoshi, A. Hakimizade, J. Mater. Sci. Mater. Electron. 27, 3941 (2016)

M.M. Momeni, M. Hakimian, A. Kazempour, Ceram. Int. 41, 13692 (2015)

S.N. Kale, S.B. Ogale, S.R. Shinde, M. Sahasrabuddhe, V. Kulkarni, R. Greene, T. Venkatesan, Appl. Phys. Lett. 82, 2100 (2003)

M. Beekmana, J. Salvadorb, X. Shic, G.S. Nolasa, J. Yangb, J. Alloys Compd. 489, 336 (2010)

P.E. de Jongh, D. Vanmaekelbergh, J.J. Kelly, Chem. Commun. 12, 1069 (1999)

T.-L. Li, Y.-L. Lee, H. Teng, J. Energy Environ. Sci. 5, 5315 (2012)

H.Y. Xu, C. Chen, L. Xu, J.K. Dong, Thin Solid Films 527, 76 (2013)

M.M. Momeni, Y. Ghayeb, Appl. Phys. A 122, 620 (2016)

M.M. Momeni, M. Hakimian, A. Kazempour, Surf. Eng. 32, 514 (2016)

M.M. Momeni, Y. Ghayeb, M. Davarzadeh, J. Alloys Compd. 637, 393 (2015)

M.M. Momeni, Y. Ghayeb, J. Solid State Electrochem. 20, 683 (2016)

M.M. Momeni, Y. Ghayeb, J. Mater. Sci. Mater. Electron. 27, 3318 (2016)

M.M. Momeni, Mater. Res. Innov. 20, 317 (2016)

S.H. Jeong, E.S. Aydil, J. Cryst. Growth 311, 4188 (2009)

X. Yu, X. Li, G. Zheng, Y. Wei, A. Zhang, B. Yao, Appl. Surf. Sci. 270, 340 (2013)

M. Vila, C. Díaz-Guerra, J. Piqueras, J. Phys. D Appl. Phys. 43, 135403 (2010). doi:10.1088/0022-3727/43/13/135403

Q. Zhang, W. Fan, L. Gao, Appl. Catal. B 76, 168 (2007)

G.B. Dong, M. Zhang, W. Lan, P.M. Dong, X.P. Zhao, H. Yan, J. Mater. Sci. Mater. Electron. 20, 193 (2009)

A.N. Banerjee, S. Nandy, C.K. Ghosh, K.K. Chattooadhyay, Thin Solid Films 515, 7324 (2007)

M.M. Momeni, M. Mirhosseini, M. Chavoshi, Ceram. Int. 42, 9133 (2016)

M.M. Momeni, Z. Nazari, Ceram. Int. 42, 8691 (2016)

M. Abdel Rafea, N. Roushdy, J. Phys. D: Appl. Phys. 42, 015413 (2008)

M.M. Momeni, A.A. Mozafari, J. Mater. Sci. Mater. Electron. (2016). doi:10.1007/s10854-016-5163-4

M.M. Momeni, Y. Ghayeb, A.A. Mozafari, J. Mater. Sci. Mater. Electron. (2016). doi:10.1007/s10854-016-5240-8

A. Vasuhi, R. John Xavier, R. Chandramohan, S. Muthkumaran, K. Dhanabalan, M. Ashokkumar, P. Parameswaren, J. Mater. Sci. Mater. Electron. 25, 824 (2014)

S.M. Hosseinpour-Mashkani, M. Ramezani, A. Sobhani-Nasab, M. Esmaeili-Zare, J. Mater. Sci. Mater. Electron. 26, 6086 (2015)

S.M. Hosseinpour-Mashkani, M. Maddahfar, A. Sobhani-Nasab, J. Electron. Mater. 45, 3612 (2016)

S.M. Hosseinpour-Mashkani, M. Maddahfar, A. Sobhani-Nasab, J. Mater. Sci. Mater. Electron. 27, 474 (2016)

V. Senthamilselvi, K. Saravanakumar, R. Anandhi, A.T. Ravichandran, K. Ravichandran, Optoelectron. Adv. Mater. Rapid Commun. 5, 1072 (2011)

P.-H. Hsieh, Y.-M. Lu, W.-S. Hwang, J.-J. Yeh, W.-L. Jang, Surf. Coat. Technol. 205, S206 (2010)

M.M. Momeni, Y. Ghayeb, J. Electroanal. Chem. 751, 43 (2015)

M.M. Momeni, Y. Ghayeb, J. Appl. Electrochem. 45, 557 (2015)

M.M. Momeni, Y. Ghayeb, M. Davarzadeh, J. Electroanal. Chem. 739, 149 (2015)

M.M. Momeni, Appl. Surf. Sci. 357, 160 (2015)

S. Wang, H. Xu, L. Qian, X. Jia, J. Wang, Y. Liu, W. Tang, J. Solid State Chem. 182, 1088 (2009)

N. Ekthammathat, T. Thongtem, S. Thongtem, Appl. Surf. Sci. 277, 211 (2013)

R.P. Pal Singh, I.S. Hudiara, S. Panday, P. Kumar, S.B. Rana, Int. J. Nanoelectron. Mater. 9, 1 (2016)

A.T. Ravichandran, K. Dhanabalan, K. Ravichandran, R. Mohan, K. Karthika, A. Vasuhi, B. Muralidharan, Acta Metall. Sin. (Engl. Lett.) 28, 1041 (2015)

K. Maaz, A. Mumtaz, S.K. Hasanian, A. Ceylan, J. Magn. Magn. Mater. 308, 289 (2007)

D.P. Joseph, T.P. David, S.P. Raja, C. Venkateswaran, Mater. Charact. 59, 1137 (2008)

J. Antony, Y. Qiang, M. Faheem, D. Meyer, D.E. McCready, M.H. Engelhard, Appl. Phys. Lett. 90, 013106 (2007)

Acknowledgements

Our special thanks to Dr. R. Chandramohan, Principal, Sree Sevugan Annamalai College, Devakottai, Tamilnadu, India, for his kind encouragement. The Principal author A. T. Ravichandran thanks, UGC-MRP: F.No 41-937/2012(SR), New Delhi for the partial funding of the work through a major research Grant.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dhanabalan, K., Ravichandran, A.T., Ravichandran, K. et al. Effect of Co doped material on the structural, optical and magnetic properties of Cu2O thin films by SILAR technique. J Mater Sci: Mater Electron 28, 4431–4439 (2017). https://doi.org/10.1007/s10854-016-6072-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-6072-2