Abstract

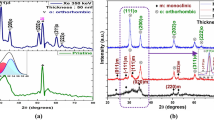

In the present work, HfO2 thin film (100 nm) has been deposited by sputtering technique and annealed at various temperatures ranging from 400 to 1000 °C (in step of 200 °C) in O2 ambient for 10 min. The samples have been characterized using XRD, FTIR, EDAX, AFM and Laser Ellipsometer. The impact of annealing temperatures in O2 ambient on structural properties such as crystallite size, phase, orientation, stress have been studied using XRD. The Hf–O phonon peaks in the infrared absorption spectrum are detected at 512, 412 cm−1. The stretching vibration modes at 720 and 748 cm−1 correspond to HfO2. AFM data show mean grain size in the range of 38–67 nm. The film reveals variation in structural properties, which appears to be responsible for variation in oxygen percentage, refractive index (1.96–2.01) at 632 nm wavelength and roughness (6.13–16.40 nm). Annealing temperature as well as ambient condition has significant effects on stress, crystal size and thus the arrangement of atoms. For good quality film, annealing temperature larger than 600 °C is desired.

Similar content being viewed by others

References

M. Vargas, N.R. Murphy, C.V. Ramana, Opt. Mater. (2014). doi:10.1016/j.optmat.2014.08.005

K.K. Bharathi, N.R. Kalidindi, C.V. Ramana, J. Appl. Phys. (2010). doi:10.1063/1.3499325

A. Cantas, G. Aygun, R. Tarun, Appl. Surf. Sci. (2014). doi:10.1016/j.apsusc.2014.03.077

A. Srivastava, R.K. Nahar, C.K. Sarkar, J. Mater. Sci. Mater. Electron. (2011). doi:10.1007/s10854-010-0230-8

Y. Zhang, K. Onodera, R. Maeda, Jpn. J. Appl. Phys. (2006). doi:10.1143/JJAP.45.300

Y. Zhang, L. Jian, K. Onodera, R. Maeda, Sens. Actuators A (2007). doi:10.1016/j.sna.2007.02.005

J. Tsaur, K. Onodera, T. Kobayashi, Z.J. Wang, S. Heisig, R. Maeda, T. Suga, Sens. Actuators A Phys. (2005). doi:10.1016/j.sna.2005.01.026

X.J. He, Z.Q. Lv, B. Liu, Z.H. Li, Sens. Actuators A (2012). doi:10.1016/j.sna.2012.03.013

Q. Fang, J.-Y. Zhang, Z. Wang, M. Modreanu, B.J. O’Sullivan, P.K. Hurley, T.L. Leedham, D. Hywel, M.A. Audier, C. Jimenez, J.-P. Senateur, I.W. Boyd, Thin Solid Films (2004). doi:10.1016/j.tsf.2003.11.186

R. Thielsch, A. Gatto, J. Heber, N. Kraiser, Thin Solid Films (2002). doi:10.1016/S0040-6090(02)00208-0

G. He, M. Liu, L.Q. Zhu, M. Chang, Q. Fang, L.D. Zhang, Surf. Sci. (2005). doi:10.1016/j.susc.2004.11.042

O. Tuna, Y. Selamet, G. Aygun, L. Ozyuzer, J. Phys. D Appl. Phys. (2010). doi:10.1088/0022-3727/43/5/055402

J. Zhu, Z.G. Liu, Y. Feng, J. Phys. D Appl. Phys. (2003). doi:10.1088/0022-3727/36/23/028

M.J. Madou, Fundamentals of microfabrication: the science of miniaturization (CRC Press, Boca Raton, 2002)

R.K. Nahar, V. Singh, Microelectron. Int. Int. J. (2010). doi:10.1108/13565361011034777

S. Hall, O. Buiu, I.Z. Mitrovic, Y. Lu, W.M. Davey, J. Telecommun. Inf. Technol. 2, 33–43 (2007)

K.V.L.V. Narayanachari, H. Chandrasekar, A. Banerjee, K.B.R. Varma, R. Ranjan, N. Bhat, S. Raghavan, Condens. Matter Mater. Sci. (2015) arXiv preprint arXiv:1503.08299

K.V.L.V. Narayanachariand, S. Raghavan, J. Appl. Phys. (2012). doi:10.1063/1.4757924

B.D. Cullity, S.R. Stock, Elements of X-ray Diffraction, 3rd edn. (Prentice-Hall Inc., Englewood Cliffs, 2001)

S.K. Gupta, J. Singh, K. Anbalagan, P. Kothari, R.R. Bhatia, Appl. Surf. Sci. (2013). doi:10.1016/j.apsusc.2012.10.113

M.C. Cisneros-Morales, C.R. Aita, Appl. Phys. Lett. (2010). doi:10.1063/1.3428965

Joint Committee on Powder Diffraction Standards Card No. 78-0050

D.A. Neumayer, E. Cartier, J. Appl. Phys. (2001). doi:10.1063/1.1382851

M. Toledano-Luque, E. San Andres, A. del Prado, I. Martil, M.L. Lucia, G. Gonzalez-Diaz, J. Appl. Phys. (2007). doi:10.1063/1.2769959

D.A. Neumayer, E. Cartier, J. Appl. Phys. (2001). doi:10.1063/1.1382851

G. He, L.D. Zhang, Q. Fang, J. Appl. Phys. (2006). doi:10.1063/1.2361161

G.B. Alers, D.J. Werder, Y. Chabal, H.C. Lu, E.P. Gusev, E. Garfunkel, T. Gustafsson, R.S. Urdahl, Appl. Phys. Lett. (1998). doi:10.1063/1.122191

T.C. Chen, C.Y. Peng, C.H. Tseng, M.H. Liao, M.H. Chen, C.I. Wu, M.Y. Chern, P.J. Tzeng, C.W. Liu, IEEE Trans. Electron. Devices (2007). doi:10.1109/TED.2007.892012

G. Aygun, I. Yildiz, J. Appl. Phys. (2009). doi:10.1063/1.3153953

J.C. Hackley, T. Gougousi, Thin Solid Films (2009). doi:10.1016/j.tsf.2009.04.033

F.L. Martinez, M. Toledano-Luque, J.J. Gandia, J. Carabe, W. Bohne, J. Rohrich, E. Strub, I. Martil, J. Phys. D Appl. Phys. (2007). doi:10.1088/0022-3727/40/17/037

M. Ramzan, A.M. Rana, E. Ahmed, M.F. Wasiq, A.S. Bhatti, M. Hafeez, A. Ali, M.Y. Nadeem, Mater. Sci. Semicond. Process. (2015). doi:10.1016/j.mssp.2014.12.079

C.Y. Ma et al., Thin Solid Films (2013). doi:10.1016/j.tsf.2013.08.068

B. Deng et al., J. Mater. Sci. Mater. Electron. (2014). doi:10.1007/s10854-014-2144-3

G. He et al., Surf. Sci. (2005). doi:10.1016/j.susc.2004.11.042

Acknowledgments

I am grateful to Dr. Chandershekhar, Ex-Director, CSIR-CEERI, Pilani for giving me the opportunity to carry out the research work at CSIR-CEERI Pilani. I sincerely thank Mr. Triloki, Senior Researcher, BHU, Varansai for his invaluable guidance and help. I also express my thanks to Mr. Ashok, Technical Assistant, Banasthali University, Banasthali and Mr. Sanjeev Kumar, Scientist, CSIR-CEERI Pilani, for carrying out XRD and AFM experiment, respectively. The authors acknowledge the financial assistance under network Project-PSC0201, Council of Scientific and Industrial Research (CSIR). Author is grateful to HRDG, CSIR, for granting Senior Research Fellowship.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pandey, S., Kothari, P., Sharma, S.K. et al. Impact of post deposition annealing in O2 ambient on structural properties of nanocrystalline hafnium oxide thin film. J Mater Sci: Mater Electron 27, 7055–7061 (2016). https://doi.org/10.1007/s10854-016-4663-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-4663-6