Abstract

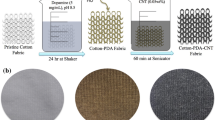

Conductive fiber plays increasingly important role in the field of multifunctional textile and smart clothing for the signal/power transmission, electrothermal function and so on. However, their major bottle necks are rigid, undyeable and limited durability. In this study, we manufactured a dyeable, washable and flexible conductive yarn by wrapping cotton roving fiber (wrapped fiber) on the surface of Carbon Nanotube (CNT) fiber (core yarn) and twisting them together by core-spun yarn spinning technique, named as cotton wrapped CNT yarn (CWC yarn). The appearance and flexibility of the CWC yarn are similar with the cotton yarn, but showing excellent conductivities of 100 Ω/cm, (undyed CWC yarn) and 50 Ω/cm (dyed CWC yarn). The electrothermal temperature of the CWC yarn with length of 5 cm reached 70 °C with applied voltage of 20 V, which was even higher than that of the pristine CNT yarn (60 °C). Furthermore, its electrical and electrothermal property changed slightly after being loaded, bent, knotted, fold-released (100 cycles) and washed, showing excellent durability. In addition, the electrochromatically dyed CWC yarn after weaving or embroidering into fabrics displayed changed colors with the various applied voltages. This work demonstrated a simple and referential method to design dyeable and washable multifunctional yarns for wearable applications.

Similar content being viewed by others

References

Wang W, Yu A, Zhai J, Wang ZL (2021) Recent progress of functional fiber and textile triboelectric nanogenerators: towards electricity power generation and intelligent sensing. Adv Fiber Mater. https://doi.org/10.1007/s42765-021-00077-9

Cai G, Yang M, Pan J, Cheng D, Xia Z, Xin W, Tang B (2018) Large-scale production of highly stretchable CNT/Cotton/Spandex composite yarn for wearable applications. ACS Appl Mater Interfaces 10(38):32726–32735. https://doi.org/10.1021/acsami.8b11885

Liu W, Liu N, Gao Y, Wang S, Cheng Q, Xu F (2018) Strain sensing fabric integrated with carbon nanotube yarn for wearable applications. Text Res J 89(15):3048–3055. https://doi.org/10.1177/0040517518807441

Nela L, Tang J, Cao Q, Tulevski GS, Han SJ (2018) Large-Area high-performance flexible pressure sensor with carbon nanotube active matrix for electronic skin. Nano Lett 18(3):2054–2059. https://doi.org/10.1021/acs.nanolett.8b00063

Lv S, Shuai L, Ding W, Ke W, Wang B, Wan J (2021) Flexible humidity sensitive fiber with swellable metal-organic frameworks. Adv Fiber Mater 3(2):107–116. https://doi.org/10.1007/s42765-021-00064-0

Xu F, Aouraghe MA, Xie X, Zheng L, Fu KK (2021) Highly stretchable, fast thermal response carbon nanotube composite heater. Compos Part A: Appl Sci Manuf 147(19):106471. https://doi.org/10.1016/j.compositesa.2021.106471

Xue L, Fan W, Yu Y, Dong K, Liu C, Sun Y, Zhang C, Chen W, Lei R, Rong K, Wang Q (2021) A novel strategy to fabricate core-sheath structure piezoelectric yarns for wearable energy harvesters. Adv Fiber Mater 3:239–250. https://doi.org/10.1007/s42765-021-00081-z

Meng J, Nie W, Zhang K, Xu F, Ding X, Wang S, Qiu Y (2018) Enhancing electrochemical performance of graphene fiber-based supercapacitors by plasma treatment. ACS Appl Mater Interfaces 10(16):13652–13659. https://doi.org/10.1021/acsami.8b04438

Wu J, Wang Z, Liu W, Wang L, Xu F (2019) Bioinspired superelastic electroconductive fiber for wearable electronics. ACS Appl Mater Interfaces 11(47):44735–44741. https://doi.org/10.1021/acsami.9b16051

Qin Y, Peng Q, Ding Y, Lin Z, Wang C, Li Y, Xu F, Li J, Yuan Y, He X, Li Y (2015) Lightweight, superelastic, and mechanically flexible graphene/polyimide nanocomposite foam for strain sensor application. ACS Nano 9(9):8933–8941. https://doi.org/10.1021/acsnano.5b02781

Cai G, Yang M, Pan J, Cheng D, Xia Z (2018) Large-Scale production of highly stretchable CNT/Cotton/Spandex composite yarn for wearable applications. ACS Appl Mater Interfaces 10(38):32726–32735. https://doi.org/10.1021/acsami.8b11885

He X, Zhang F, Wang R, Liu W (2007) Preparation of a carbon nanotube/carbon fiber multi-scale reinforcement by grafting multi-walled carbon nanotubes onto the fibers. Carbon 45(13):2559–2563. https://doi.org/10.1016/j.carbon.2007.08.018

Yuan Y, Yin W, Yang M, Xu F, Zhao X, Li J, Peng Q, He X, Du S, Li Y (2018) Lightweight, flexible and strong core-shell non-woven fabrics covered by reduced graphene oxide for high-performance electromagnetic interference shielding. Carbon 130:59–68. https://doi.org/10.1016/j.carbon.2017.12.122

Li X, Zhou C, Overman N, Ma XL, Canfield N, Kappagantula K, Schroth J, Grant G (2021) Copper carbon composite wire with a uniform carbon dispersion made by friction extrusion. J Manuf Process 65:397–406. https://doi.org/10.1016/j.jmapro.2021.03.055

Liu W, Xu F, Zhu N, Wang S (2016) Mechanical and electrical properties of carbon nanotube / polydimethylsiloxane composites yarn. J Eng Fiber Fabr 210(3):594–599. https://doi.org/10.1002/pssa.201228549

Wei L, Xu F, Sun L, Wei L, Qiu Y (2016) A novel flexible humidity switch material based on multi-walled carbon nanotube/polyvinyl alcohol composite yarn. Sens Actuat B Chem 230:528–535. https://doi.org/10.1016/j.snb.2016.02.108

Wen YH, Tsou CH, de Guzman MR, Huang D, Yu YQ, Gao C, Zhang XM, Du J, Zheng YT, Zhu H, Wang ZH (2021) Antibacterial nanocomposite films of poly(vinyl alcohol) modified with zinc oxide-doped multiwalled carbon nanotubes as food packaging. Polym Bull. https://doi.org/10.1007/s00289-021-03666-1

Mirzaeifar R, Qin Z, Buehler MJ (2015) Mesoscale mechanics of twisting carbon nanotube yarns. Nanoscale 7(12):5435–5445. https://doi.org/10.1039/c4nr06669c

Shang Y, He X, Li Y, Zhang L, Li Z, Ji C, Shi E, Li P, Zhu K, Peng Q, Wang C, Zhang X, Wang R, Wei J, Wang K, Zhu H, Wu D, Cao A (2012) Super-stretchable spring-like carbon nanotube ropes. Adv Mater 24(21):2896–2900. https://doi.org/10.1002/adma.201200576

Li W, Xu F, Wang Z, Wu J, Liu W, Qiu Y (2016) Effect of thermal treatments on structures and mechanical properties of aerogel-spun carbon nanotube fibers. Mater Lett 183:117–121. https://doi.org/10.1016/j.matlet.2016.07.034

Wang Z, Wu J, Wei X, Saleemi S, Liu W, Li W, Marriam I, Xu F (2019) Bioinspired microstructure-reorganized behavior of carbon nanotube yarn induced by cyclic stretching training. J Mater Chem C 8(1):117–123. https://doi.org/10.1039/c9tc06056a

Hu G, Zhang X, Liu X, Yu J, Ding B (2020) Strategies in precursors and post treatments to strengthen carbon nanofibers. Adv Fiber Mater 2(2):46–63. https://doi.org/10.1007/s42765-020-00035-x

Shao Y, Xu F, Liu W, Zhou M, Li W, Hui D, Qiu Y (2017) Influence of cryogenic treatment on mechanical and interfacial properties of carbon nanotube fiber/bisphenol-F epoxy composite. Compos B Eng 125:195–202. https://doi.org/10.1016/j.compositesb.2017.05.077

Misak HE, Asmatulu R, Omalley M, Jurak E, Mall S (2014) Functionalization of carbon nanotube yarn by acid treatment. Int J Smart Nano Mater 5(1):34–43. https://doi.org/10.1080/19475411.2014.896426

Shao Y, Xu F, Marriam I, Liu W, Gao Z, Qiu Y (2019) Quasi-static and dynamic interfacial evaluations of plasma functionalized carbon nanotube fiber. Appl Surf Sci 465:795–801. https://doi.org/10.1016/j.apsusc.2018.09.258

Kanakaraj SN, Hsieh YY, Adusei PK, Homan B, Fang Y, Zhang G, Mishra S, Gbordzoe S, Shanov V (2019) Nitrogen-doped CNT on CNT hybrid fiber as a current collector for high-performance Li-ion capacitor. Carbon 149:407–418. https://doi.org/10.1016/j.carbon.2019.04.032

Aouraghe MA, Xu F, Liu X, Qiu Y (2019) Flexible, quickly responsive and highly efficient E-heating carbon nanotube film. Compos Sci Technol 183:107824. https://doi.org/10.1016/j.compscitech.2019.107824

Xu F, Wei B, Liu W, Zhu H, Zhang Y, Qiu Y (2015) In-plane mechanical properties of carbon nanotube films fabricated by floating catalyst chemical vapor decomposition. J Mater Sci 50(24):8166–8174. https://doi.org/10.1007/s10853-015-9395-0

Du S, Zhao W, Yuan L (2012) Absorption and structural property of ethanol/water mixture with carbon nanotubes. Chin J Chem Phys 25(4):487–493. https://doi.org/10.1088/1674-0068/25/04/487-493

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Stephen Eichhorn.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jia, K., Chen, W., Wang, J. et al. Dyeable electroconductive cotton wrapped CNT yarn for multifunctional textiles. J Mater Sci 57, 731–738 (2022). https://doi.org/10.1007/s10853-021-06597-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06597-4