Abstract

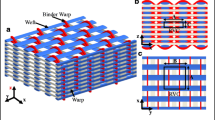

The evaluation of the stress field distribution of warp-reinforced 2.5D woven composites using meso-scale voxel-based model is described. The idealized geometry model is established by using measured parameters from the CT image. Comparison between voxel-based finite element method and experimental measurements is included. The results show that the proposed meso-scale voxel-based method is capable of accurately predicting the mechanical properties of warp-reinforced 2.5D woven composites, validated by the comparison of the initial modulus, max stress as well as the failure modes. Also, the numbers of representative volume element have an important effect on mechanical behaviors of warp-reinforced 2.5D woven composites.

Similar content being viewed by others

References

Mouritz AP, Bannister MK, Falzon PJ, Leong KH (1999) Review of applications for advanced three-dimensional fiber textile composites. Compos Part A Appl Sci 30(12):1445–1461

Naik NK, Azad SKNM, Durga PP (2002) Stress and failure analysis of 3D angle interlock woven composites. J Compos Mater 36(1):93–123

Fang GD, Bassam ES, Dmitry I, Stephen RH (2016) Smoothing artificial stress concentrations in voxel-based models of textile composites. Compos Part A Appl Sci 80:270–284

Lomov SV, Gusakov AV, Huysmans G, Prodromou A, Verpoest I (2000) Textile geometry preprocessor for meso-mechanica models of woven composites. Compos Sci Technol 60:2083–2095

Hallal A, Younes R, Fardoun F, Nehme S (2012) Improved analytical model to predict the effective elastic properties of 2.5D interlock woven fabrics composite. Compos Struct 94(10):3009–3028

Kwon YW, Kim DH, Chu T (2006) Multi-scale modeling of refractory woven fabric composites. J Mater Sci 41:6647–6654. doi:10.1007/s10853-006-0195-4

Boisse P, Gasser A, Hagege B, Bolloet JL (2005) Analysis of the mechanical behavior of woven fibrous material using virtual tests at the unit cell level. J Mater Sci 40:5955–5962. doi:10.1007/s10853-005-5069-7

Cox BN, Dadkhah MS (1995) The macroscopic elasticity of 3D woven composites. J Comput Mater 29:785–819

Iarve EV, Mollenhauer DH, Zhou EG, Breitzman T, Whitney TJ (2009) Independent mesh method-based prediction of local and volume average fields in textile composites. Compos Part A Appl Sci 40(12):1880–1890

Jiang WG, Hallett S, Wisnom M (2008) Development of domain superposition technique for the modelling for woven fabric composites. Mechanical response of composites. Springer, Netherlands, pp 281–291

Mahadik Y, Hallett SR (2010) Finite element modeling of tow geometry in 3D woven fabrics. Compos Part A Appl Sci 41(9):1192–1200

Lu ZX, Zhou Y, Yang ZY, Liu Q (2013) Multi-scale finite element analysis of 2.5D woven fabric composites under on-axis and off-axis tension. Compot Mater Sci 79:485–494

Song J, Wen WD, Cui HT, Zhang HJ, Xu Y (2016) Finite element analysis of 2.5D woven composites, part II: damage behavior simulation and strength prediction. Appl Compos Mater 23:45–69

Kim HJ, Swan CC (2003) Voxel-based meshing and unit-cell analysis of textile composites. Int J Numer Methods Eng 56:997–1006

Potter E, Pinho S, Robinson P, Iannucci I, McMillan AJ (2012) Mesh generation and geometrical modelling of 3D woven composites with variable tow cross-sections. Comput Mater Sci 51(1):103–111

Zhang C, Li N, Wang WZ, Binienda WK, Fang HB (2015) Progressive damage simulation of triaxially braided composite using a 3D meso-scale finite element model. Compos Struct 125:104–116

Zhang C, Xu XW (2013) Finite element analysis of 3D braided composites based on three unit-cells models. Compos Struct 98:130–142

Doitrand A, Fagiano C, Irisarri FX, Hirsekorn M (2015) Comparison between voxel and consistent meso-scale models of woven composites. Compos Part A Appl Sci 73:143–154

Isart N, Said BE, Hallett SR, Blanco N (2015) Internal geometric modelling of 3D woven composites: a comparison between different approaches. Compos Struct 132:1219–1230

Jin LY (2012) Research on the mechanical properties for stiffness and strength of 4D in-plain C/C composites. Master Thesis 21

Guo QW, Zhang GL, Li JL (2013) Process parameters design of a three-dimensional and five-directional braided composites joint based on finite element analysis. Mater Des 46:291–300

Dong WF, Xiao J, Li Y, Wu HQ, Zhang LQ (2005) Theoretical study on elastic properties of 2.5D braided composites. J NanJing Univ Aeronaut Astronaut 37(5):659–663

Grail G, Hirsekorn M, Wendling A, Hivet G, Hambli R (2013) Consistent finite element mesh generation for meso-scale modeling of textile composites with preformed and compacted reinforcements. Compos Part A Appl Sci 55:143–151

De Carvalho NV, Pinho ST, Robinson P (2011) Reducing the domain in the mechanical analysis of periodic structures, with application to woven composites. Compos Sci Technol 71(7):969–979

Segurado J, Llorca J (2002) A numerical approximation to the elastic properties of sphere-reinforced composites. J Mech Phys Solids 50:2107–2121

Zhang C, Xu X (2013) Application of three unit-cells models on mechanical analysis of 3D five-directional and full five-directional braided composites. Appl Compos Mater 20(5):803–825

Huang ZM, Liu L (2014) Assessment of composite failure and ultimate strength without experiment on composite. Acta Mech Sin 30(4):569–588

Wang XY, Tang YZ (1999) Mechanical analysis and designing of composite materials. National defense science and technology university press, Changsha (In Chinese)

Budiansky B, Fleck N (1993) Compressive failure of fiber composites. J Mech Phys Solids 41:183–211

Reifsnider K (1977) Some fundamental aspects of the fatigue and fracture response of composite materials. In: Proceedings of the 14th annual meeting, USA, pp 373–384

Hashin Z (1980) Failure criteria for unidirectional fiber composite. J Appl Mech 47:329–334

Cordebois J, Sidoroff F (1980) Anisotropic damage in elasticity and plasticity. Journal de mecanique theorique et appliquee 45–59

Fang GD, Liang J, Wang BL (2009) Progressive damage and nonlinear analysis of 3D four-directional braided composites under unidirectional tension. Compos Struct 89:126–133

Zhang DT, Chen L, Sun Y, Wang XM (2015) Transverse tensile damage behaviors of three-dimensional five-directional braided composites by meso-scale finite element approach. J Reinf Plast Compos 34(15):1202–1220

Acknowledgements

This work was supported by the Key Research Projects of China (No. 2016YFC-0304301), Scientific and Technological Transformative Project of Jiangsu Province (No. BA2016170) and Natural Science Foundation of Jiangsu Province (No. BK20160157).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, D., Chen, L., Wang, Y. et al. Stress field distribution of warp-reinforced 2.5D woven composites using an idealized meso-scale voxel-based model. J Mater Sci 52, 6814–6836 (2017). https://doi.org/10.1007/s10853-017-0921-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0921-0