Abstract

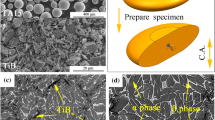

An in situ (TiB + TiC)/Ti-1100 composite was prepared by reacting B4C and Ti. The effect of the amount of deformation during thermomechanical processing (TMP) on the microstructure, orientation of TiB whiskers, and the mechanical properties of the composite were investigated. Improvements in the composite tensile strength from TMP are discussed in terms of grain refinement and TiB whisker rotation. A model is suggested to predict the TiB whisker orientation factor for the composite after TMP with various amounts of deformation. Based on the effect of grain refinement and rotation of the TiB whiskers, the yield strengths of the composite after TMP with various amounts of deformation were modeled. The modeled values agreed well with the test results.

Similar content being viewed by others

References

Ibrahim IA, Mohamed FA, Lavernia EJ (1991) Particulate reinforced metal matrix composites—a review. J Mater Sci 26:1137–1156. doi:10.1007/BF00544448

Ray K, Poole WJ, Mitchell A, Hawbolt EB (1997) In: Weiss I, Srinivasan R, Bania P, Eylon D, Semiatin SL (eds) Advances in the science and technology of titanium alloy processing. TMS, Warrendale, p 201

Ma FC, Lu WJ, Qin JN, Zhang D (2007) Hot deformation behavior of in situ synthesized Ti composite reinforced with 5 vol.% (TiB + TiC) particles. J Mater Sci 42:6901–6906. doi:10.1007/s10853-006-1303-1

Lu WJ, Zhang D (2005) Fabrication, microstructure and mechanical properties of in situ synthesized titanium matrix composites. High Education Press, Beijing

Luetjering G, Albrecht J, Gysler A (1993) In: Froes FH, Caplan I (eds) Titanium’92 science and technology. TMS, Warrendale, pp 163–165

Ma FC, Wang TR, Liu P, Li W, Liu XK, Chen XH, Pan D, Lu WJ (2016) Mechanical properties and strengthening effects of in situ (TiB + TiC)/Ti-1100 composite at elevated temperatures. Mater Sci Eng A 654:352–358

Cho W, Jones JW, Allison JE, Donlon WT (1989) In: Lacomb P, Tricot R, Beranger G (eds) Proceedings of the 6th World conference on titanium. Les Editions de Physique, Paris, p 187

Williams JC, Luetjering G (1981) Titanium’80 science and technology. Warrendale, AIME, p 671

Bania PJ, Hall JA (1985) Titanium science and technology. Oberursel, Deutsche Gesellschaft fur Metallkunde, p 2371

Seagle SR, Hall GS, Bomberger HB (1975) High temperature properties of Ti-6Al-2Sn-4Zr-2Mo-0. 09Si. Met Eng Q 15:48–54

Wang W, Zeng WD, Xue C, Liang XB, Zhang JW (2014) Designed bimodal size lamellar O microstructures in TiAlNb based alloy: microstructural evolution, tensile and creep properties. Mater Sci Eng A 618:288–294

Miller WH, Chen RT, Starke EA (1987) Ambient- and high-temperature properties of titanium carbide-titanium boride composite fabricated by transient plastic phase processing. Metall Trans A 18:451–455

Gorsse S, Miracle DB (2003) Mechanical properties of Ti-6Al-4V/TiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater 51:2427–2442

Guillard S, Thirukkonda M, Chaudhury PK (1997) In: Weiss I, Srinivasan R, Bania P, Eylon D, Semiatin SL (eds) Advances in the science and technology of titanium alloy processing. TMS, Warrendale, pp 93–100

Kin WY (1992) Microstructural evolution and mechanical properties of a forged gamma titanium aluminide alloy. Acta Metall 40:1121–1134

Lu WJ, Zhang D, Wu RJ, Mori H (2002) Preparing TiC titanium-matrix composites using in situ technology. Metall Trans A 33:3055–3059

Lu WJ, Zhang D, Zhang XN, Wu RJ, Sakata T, Mori H (2001) Microstructure and tensile properties of in situ (TiB + TiC)/Ti6264 (TiB:TiC = 1:1) composites prepared by common casting technique. Mater Sci Eng A 311:142–150

Guo XL, Wang LQ, Wang MM, Qin JN, Zhang D, Lu WJ (2012) Effects of degree of deformation on the microstructure, mechanical properties and texture of hybrid-reinforced titanium matrix composites. Acta Mater 60:2656–2667

Ma FC, Lu WJ, Qin JN, Ji B, Zhang D (2007) Effect of forging and heat treatment on the microstructure of in situ TiC/Ti-1100 composites. J Alloys Comp 428:332–337

Ma FC, Lu WJ, Qin JN, Zhang D (2006) Microstructure evolution of near α titanium alloys during thermomechanical processing. Mater Sci Eng A416:59–65

Cox H (1952) The elasticity and strength of paper and other fibrous materials. J Appl Phys 3:72–79

Fukuda H, Chou TW (1982) Probabilistic theory of the strength of short-fibre composites with variable fibre length and orientation. J Mater Sci 17:1003–1007. doi:10.1007/BF00543519

Bader MG, Chou TW, Quigley JJ (1978) Proceedings of the symposiums on new developments and applications in composites. TMS-AIME, St. Louis

Xiao L, Lu WJ, Qing JN, Chen YF, Zhang D, Wang MM (2009) Steady state creep of in situ TiB plus La2O3 reinforced high temperature titanium matrix composite. Mater Sci Eng A 499:500–504

Hall EO (1951) The deformation and aging of mild steel. Proc Phys Soc London B 64:747–752

Sen I, Tamirisakandala S, Miracle DB, Ramamurty U (2007) Microstructural effects on the mechanical behavior of B-modified Ti-6Al-4V alloys. Acta Mater 55:4983–4993

Sauer C, Lütjering G (2001) Influence of α layers at β grain boundaries on mechanical properties of Ti-alloys. Mater Sci Eng A 319–321:393–397

Rosenberg HW, Jaffee RI, Promisel NE (eds) (1968) The science, technology and application of titanium. Pergamon, New York, p 851

Acknowledgements

The authors would like to acknowledge the financial support provided by the National Research Fund of Science and Technology Commission of Shanghai Municipality under Grant Nos. 09ZR1422100 and 11441900501, the Innovation Research Fund of Shanghai Municipal Commission of Education under Grant No. 10YZ94, and the Key Laboratory of Advanced Metal-Based Electrical Power Materials.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ma, F., Zheng, B., Liu, P. et al. Modeling of effects of thermomechanical processing on elevated-temperature mechanical properties of in situ (TiB + TiC)/Ti-1100 composite. J Mater Sci 51, 7502–7511 (2016). https://doi.org/10.1007/s10853-016-0029-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0029-y