Abstract

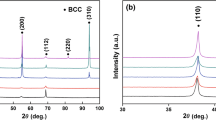

Compression properties of a refractory multi-component alloy, Ta20Nb20Hf20Zr20Ti20, were determined in the temperature range of 296–1473 K and strain rate range of 10−1–10−5 s−1. The properties were correlated with the microstructure developed during compression testing. The alloy was produced by vacuum arc melting, and it was hot isostatically pressed (HIPd) and homogenized at 1473 K for 24 h prior to testing. It had a single-phase body-centered cubic structure with the lattice parameter a = 340.4 pm. The grain size was in the range of 100–200 μm. During compression at a strain rate of έ = 10−3 s−1, the alloy had the yield strength of 929 MPa at 296 K, 790 MPa at 673 K, 675 MPa at 873 K, 535 MPa at 1073 K, 295 MPa at 1273 K and 92 MPa at 1473 K. Continuous strain hardening and good ductility (ε ≥ 50%) were observed in the temperature range from 296 to 873 K. Deformation at T = 1073 K and έ ≥ 10−3 s−1 was accompanied by intergranular cracking and cavitation, which was explained by insufficient dislocation and diffusion mobility to accommodate grain boundary sliding activated at this temperature. The intergranular cracking and cavitation disappeared with an increase in the deformation temperature to 1273 and 1473 K or a decrease in the strain rate to ~10−5 s−1. At these high temperatures and/or low-strain rates the alloy deformed homogeneously and showed steady-state flow at a nearly constant flow stress. Partial dynamic recrystallization, leading to formation of fine equiaxed grains near grain boundaries, was observed in the specimens deformed at 1073 and 1273 K and completed dynamic recrystallization was observed at 1473 K.

Similar content being viewed by others

References

Subramanian PR, Mendiratta MG, Dimiduk DM, Stucke MA (1997) Mater Sci Eng A239-240:1

Bewlay BP, Jackson MR, Zhao JC, Subramanian PR (2003) Metall Mater Trans 34A:2043

Perepezko JH (2009) Science 326(5956):1068

Yeh J-W, Chen S-K, Lin S-J, Gan J-Y, Chin T-S, Shun T–T, Tsau C-H, Chang S-Y (2004) Adv Eng Mater 6(5):299

Yeh J-W (2006) Ann Chim: Sci Mater 31:633

Yeh J-W, Chen Y-L, Lin S-J, Chen S-K (2007) Mater Sci Forum 560:1

Zhou YJ, Zhang Y, Wang YL, Chen GL (2007) Mater Sci Eng A 454–455:260

Y.J. Zhou, Y. Zhang, Y.L. Wang, G.L. Chen, Appl. Phys. Lett. 90 (2007) 181904/1-3

Zhou YJ, Zhang Y, Wang FJ, Wang YL, Chen GL (2008) J Alloys Compd 466:201

Wang YP, Li BS, Ren MX, Yang C, Fu HZ (2008) Mater Sci Eng A 491:154

Wang FJ, Zhang Y (2008) Mater Sci Eng A 496:214

Wen LH, Kou HC, Li JS, Chang H, Xue XY, Zhou L (2009) Intermetallics 17:266

Tsai CW, Tsai MH, Yeh JW, Yang CC (2010) J Alloys Compd 490:160

Zhu JM, Fu HM, Zhang HF, Wang AM, Li H, Hu ZQ (2010) Mater Sci Eng A527:6975

Senkov ON, Wilks GB, Miracle DB, Chuang CP, Liaw PK (2010) Intermetallics 18:1758

Senkov ON, Wilks GB, Scott JM, Miracle DB (2011) Intermetallics 19:698

Senkov ON, Scott JM, Senkova SV, Miracle DB, Woodward CF (2011) J Alloys Comp 509:6043

Dieter GE (1986) Mechanical metallurgy, 3rd edn. McGraw-Hill, Inc., New York

McQueen HJ, Jonas JJ (1975) In: Treatise on materials science and technology, plastic deformation of materials, vol 6. Academic Press, New York, p 393

Senkov ON, Meisenkothen F, Woodward CF (2011) In: Strain localization and deformation twins in a Ta20Nb20Hf20Zr20Ti20 high-entropy alloy. Air Force Research Laboratory

Newbury DE, Joy DC, Echlin P, Fiori CE, Goldstein JI (1986) Advanced scanning electron microscopy and X-ray microanalysis. Plenum Press, New York

Mughrabi H (1993) In: Materials science and technology, plastic deformation and fracture of materials, vol 6. VCH, Cambridge, p 191

Arsenault RJ (1975) Treatise on materials science and technology, plastic deformation of materials, vol 6. Academic Press, New York, p 1

Meyers C (1999) Mechanical behavior of materials. Cambridge University Press, Cambridge

Christian JW, Mahajan S (1995) Progr Mater Sci 39:1

Mulford RA, Kocks UF (1979) Acta Metall 27:1125

Meyers MA, Vohringer O, Lubarda VA (2001) Acta Mater 49:4025

Cane BJ, Greenwood GW (1975) Metal Sci 9(1):55

Riedel H (1987) Fracture at high temperatures. Springer-Verlag New York Inc., New York

Frost HJ, Ashby MF (1982) Deformation-mechanism maps—the plasticity and creep of metals and ceramics. Pergamon Press, Oxford

Weertman J (1963) Trans AIME 227:1475

Weertman J (1968) ASM Trans 61:681

Chaudhury PK, Mohamed FA (1987) Metall Trans 18A(1987):2105

Langdon TG (1982) Metall Trans 13A:689

Sherby OD, Wadsworth J (1989) Progr Mater Sci 33:169

Jonas JJ, Sellars CM, Tegart WJM (1969) Met Rev 14: 1

Eager RL, Langmuir DB (1953) Phys Rev 89:911

Giithoff F, Hemion B, Herzig C, Petry W, Schober HR, Trampenau J (1994) J Phys: Condens Matter 6:6211

Davis BE, McMullen WD (1972) Acta Metall 20:593

Kidson G, McGurn J (1961) Canad J Phys 39:1146

Neikov OD, Naboychenko S, Gopienko VG, Frishberg IV, Lotsko DV (2009) Handbook of non-ferrous metal powders: technology and applications. Elsevier, Amsterdam

Herzig C, Köhler U, Divinski SV (1999) J Appl Phys 85:8120

Nakamura H, Koiwa M (1991) Iron Steel Inst Jpn Int 31:757

Lazarus D (1965) Diffusion in body-centered cubic metals. ASM, Cleveland, p 155

Acknowledgements

Discussions with Drs. D. Dimiduk, P. Martin, R. S. Mishra, S. Rao, S. L. Semiatin, G. Wilks, and R. Wheeler are recognized. This study was supported through the Air Force Research Laboratory Director’s Funds and through the USAF Contract No. FA8650-10-D-5226.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Senkov, O.N., Scott, J.M., Senkova, S.V. et al. Microstructure and elevated temperature properties of a refractory TaNbHfZrTi alloy. J Mater Sci 47, 4062–4074 (2012). https://doi.org/10.1007/s10853-012-6260-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6260-2