Abstract

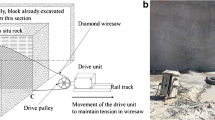

One of the key parameters that affect the selection of equipment and the cost estimation of dimension stone quarries is the rock cutting rate or production rate. In this study, the M5P tree algorithm is used to determine the relationship between the hard rock sawability and its factors especially the physical and mechanical characteristics of rock. To achieve the research goal, a variety of eleven types of hard dimension stone were selected and nine major physical and mechanical characteristics of rock including uniaxial compressive strength, Young’s modulus, Brazilian tensile strength, equivalent quarts content, grain size, Mohs hardness, point load test, density and P-wave velocity of these samples were evaluated. The cutting rate of diamond wire for all of the Workpiece was measured at different pullback amperage with a fully instrumented cutting platform in laboratory. All operational parameters of cutting process were entirely controlled. Thus, a database containing 99 datasets was provided and it has been used for analyses. The obtained results from the pruned and unpruned tree models showed a significant relationship between cutting rate and its factors. In the end, the results of M5P tree method were compared with statistical analyses (i.e., linear and nonlinear regression). The coefficient of determination be equal with 0.92, 0.86, 0.77 and 0.63 for unpruned tree, pruned tree, linear and nonlinear regression method respectively. This comparison showed that the both method of M5P tree technique have a better performance in predicting the cutting rate rather than the statistical regression methods.

Similar content being viewed by others

References

Agus M, Bortolussi A, Careddu N, Ciccu R, Grosso B, Massacci G (2005) Influence of stone properties on diamond wire performance. In: Proceedings of the 1st international congress on dimension stones. Guarapari

Ajmera TK, Goyal MK (2012) Development of stage–discharge rating curve using model tree and neural networks: an application to Peachtree Creek in Atlanta. Expert Syst Appl 39:5702–5710

Armaghani DJ, Amin MFM, Yagiz S, Faradonbeh RS, Abdullah RA (2016a) Prediction of the uniaxial compressive strength of sandstone using various modeling techniques. Int J Rock Mech Min Sci 85:174–186

Armaghani DJ, Mohamad ET, Hajihassani M, Yagiz S, Motaghedi H (2016b) Application of several non-linear prediction tools for estimating uniaxial compressive strength of granitic rocks and comparison of their performances. Eng Comput 32:189–206

Aryafar A, Mikaeil R (2016) Estimation of the ampere consumption of dimension stone sawing machine using of artificial neural networks. Int J Min Geo Eng 50:121–130

Ataei M, Mikaiel R, Sereshki F, Ghaysari N (2012) Predicting the production rate of diamond wire saw using statistical analysis. Arab J Geosci 5:1289–1295

Ayaz Y, Kocamaz AF, Karakoç MB (2015) Modeling of compressive strength and UPV of high-volume mineral-admixtured concrete using rule-based M5 rule and tree model M5P classifiers. Constr Build Mater 94:235–240

Aydin G, Karakurt I, Hamzacebi C (2014) Artificial neural network and regression models for performance prediction of abrasive waterjet in rock cutting. Int J Adv Manuf Technol 75:1321–1330

Aydin G, Karakurt I, Hamzacebi C (2015) Performance prediction of diamond sawblades using artificial neural network and regression analysis. Arab J Sci Eng 40:2003–2012

Bagherpour R, Khademian A, Almasi SN, Aalaei M (2014) Optimum cutting wire assembly situation in dimension stone quarries. J Min Metall Sect A Min 50:1–8

Balouchi B, Nikoo MR, Adamowski J (2015) Development of expert systems for the prediction of scour depth under live-bed conditions at river confluences: application of different types of ANNs and the M5P model tree. Appl Soft Comput 34:51–59

Behnood A, Olek J, Glinicki MA (2015) Predicting modulus elasticity of recycled aggregate concrete using M5′ model tree algorithm. Constr Build Mater 94:137–147

Beiki M, Majdi A, Givshad AD (2013) Application of genetic programming to predict the uniaxial compressive strength and elastic modulus of carbonate rocks. Int J Rock Mech Min Sci 63:159–169

Betrie GD, Tesfamariam S, Morin KA, Sadiq R (2013) Predicting copper concentrations in acid mine drainage: a comparative analysis of five machine learning techniques. Environ Monit Assess 185:4171–4182

Bianconi F, González E, Fernández A, Saetta SA (2012) Automatic classification of granite tiles through colour and texture features. Expert Syst Appl 39:11212–11218

Cai O, Careddu N, Mereu M, Mulas I (2007) The influence of operating parameters on the total productivity of diamond wire in cutting granite. IDR Ind Diam Rev 3:25–32

Ceryan N (2014) Application of support vector machines and relevance vector machines in predicting uniaxial compressive strength of volcanic rocks. J Afr Earth Sci 100:634–644

Chai T, Draxler RR (2014) Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci Model Dev 7:1247–1250

Dagdelenler G, Sezer EA, Gokceoglu C (2011) Some non-linear models to predict the weathering degrees of a granitic rock from physical and mechanical parameters. Expert Syst Appl 38:7476–7485

Deepa C, SathiyaKumari K, Sudha VP (2010) Prediction of the compressive strength of high performance concrete mix using tree based modeling. Int J Comput Appl 6:18–24

Deshpande N, Londhe S, Kulkarni S (2014) Modeling compressive strength of recycled aggregate concrete by artificial neural network, model tree and non-linear regression. Int J Sustain Built Environ 3:187–198

Franklin J (1985) Suggested method for determining point load strength. In: International journal of rock mechanics and mining sciences and geomechanics abstracts. Elsevier, pp 51–60

Ghasemi E, Kalhori H, Bagherpour R, Yagiz S (2016) Model tree approach for predicting uniaxial compressive strength and Young’s modulus of carbonate rocks. Bull Eng Geol Environ 1–13. doi:10.1007/s10064-016-0931-1

Ghaysari N, Ataei M, Sereshki F, Mikaiel R (2012) Prediction of performance of diamond wire saw with respect to texture characteristics of rock/Prognozowanie Wydajności Pracy Strunowej Piły Diamentowej W Odniesieniu Do Charakterystyki Tekstury Skał. Arch Min Sci 57:887–900

Huang G, Xu X (2013) Sawing performance comparison of brazed and sintered diamond wires. Chin J Mech Eng 26:393–399

Huang GQ, Huang H, Xu XP (2009) Analysis on the fracture failure of brazed diamonds in wire sawing. In: Key engineering materials. Trans Tech Publ, pp 436–441

International Society for Rock Mechanics (1981) Rock characterization, testing and monitoring: ISRM suggested methods. Pergamon, Oxford

Jain S, Rathore S (2009) Role of cut size area on the performance of diamond wire saw machine in quarrying of marble. Int J Min Reclam Environ 23:79–91

Jain S, Rathore S (2011) Prediction of cutting performance of diamond wire saw machine in quarrying of marble: a neural network approach. Rock Mech Rock Eng 44:367–371

Kahraman S, Altun H, Tezekici B, Fener M (2006) Sawability prediction of carbonate rocks from shear strength parameters using artificial neural networks. Int J Rock Mech Min Sci 43:157–164

Kainthola A, Singh P, Verma D, Singh R, Sarkar K, Singh T (2015) Prediction of strength parameters of himalayan rocks: a statistical and ANFIS approach. Geotech Geol Eng 33:1255–1278

Konstanty J (2005) Powder metallurgy diamond tools, 1st edn. Elsevier, Amsterdam

Liang M, Mohamad ET, Faradonbeh RS, Armaghani DJ, Ghoraba S (2016) Rock strength assessment based on regression tree technique. Eng Comput 32:343–354

Madhubabu N, Singh P, Kainthola A, Mahanta B, Tripathy A, Singh T (2016) Prediction of compressive strength and elastic modulus of carbonate rocks. Measurement 88:202–213

McCandless T, Haupt S, Young G (2015) A model tree approach to forecasting solar irradiance variability. Sol Energy 120:514–524

Mikaeil R, Ataei M, Hoseinie SH (2008) Predicting the production rate of diamond wire saws in carbonate rock cutting. IDR Ind Diam Rev 3:28–34

Mikaeil R, Ataei M, Ghadernejad S, Sadegheslam G (2014) Predicting the relationship between system vibration with rock brittleness indexes in rock sawing process. Arch Min Sci 59:139–153

Mikaeil R, Ozcelik Y, Ataei M, Shaffiee Haghshenas S (2016) Application of harmony search algorithm to evaluate the performance of diamond wire saw. J Min Environ. doi:10.22044/jme.2016.723

Mishra D, Basu A (2013) Estimation of uniaxial compressive strength of rock materials by index tests using regression analysis and fuzzy inference system. Eng Geol 160:54–68

Mohamad ET, Armaghani DJ, Momeni E, Abad SVANK (2015) Prediction of the unconfined compressive strength of soft rocks: a PSO-based ANN approach. Bull Eng Geol Environ 74:745–757

Monjezi M, Khoshalan HA, Razifard M (2012) A neuro-genetic network for predicting uniaxial compressive strength of rocks. Geotech Geol Eng 30:1053–1062

Nikoo MR, Karimi A, Kerachian R, Poorsepahy-Samian H, Daneshmand F (2013) Rules for optimal operation of reservoir-river-groundwater systems considering water quality targets: application of M5P model. Water Resour Manag 27:2771–2784

Onyari E, Ilunga F (2013) Application of MLP neural network and M5P model tree in predicting streamflow: a case study of Luvuvhu catchment, South Africa. Int J Innov Manag Technol 4:11

Özçelik Y (2005) Optimum working conditions of diamond wire cutting machines in the marble industry. IDR Ind Diam Rev 1:58–64

Ozcelik Y, Yilmazkaya E (2011) The effect of the rock anisotropy on the efficiency of diamond wire cutting machines. Int J Rock Mech Min Sci 48:626–636

Quinlan JR (1992) Learning with continuous classes. In: 5th Australian joint conference on artificial intelligence. Singapore, pp 343–348

Sabbaghi S, Maleki R, Shariaty-Niassar M, Zerafat M, Nematollahi M (2012) Modeling of chloride ion separation by nanofiltration using machine learning techniques. Int J Nanosci Nanotechnol 8:185–190

Sadegheslam G, Mikaeil R, Rooki R, Ghadernejad S, Ataei M (2013) Predicting the production rate of diamond wire saws using multiple nonlinear regression analysis. Geosyst Eng 16:275–285

Samani HY, Bafghi ARY (2012) Prediction of the sawing quality of Marmarit stones using the capability of artificial neural network. Int J Numer Anal Meth Geomech 36:881–891

Singh P, Tripathy A, Kainthola A, Mahanta B, Singh V, Singh T (2017) Indirect estimation of compressive and shear strength from simple index tests. Eng Comput 33:1–11

Taneja S (2014) Implementation of novel algorithm (SPruning Algorithm). J Comput Eng 16:57–65

Tiryaki B (2008) Predicting intact rock strength for mechanical excavation using multivariate statistics, artificial neural networks, and regression trees. Eng Geol 99:51–60

Tumac D (2016) Artificial neural network application to predict the sawability performance of large diameter circular saws. Measurement 80:12–20

Vasconcelos G, Lourenço PB, Alves C, Pamplona J (2007) Prediction of the mechanical properties of granites by ultrasonic pulse velocity and Schmidt hammer hardness. In: Proceedings of the 10th North American masonry conference, USA, pp 980–991

Wang Y, Witten IH (1996) Induction of model trees for predicting continuous classes. Working paper series 478X. New Zealand, 23:1–12

Witten IH, Frank E (2005) Data mining: practical machine learning tools and techniques. Morgan Kaufmann, Burlington

Yesiloglu-Gultekin N, Sezer EA, Gokceoglu C, Bayhan H (2013) An application of adaptive neuro fuzzy inference system for estimating the uniaxial compressive strength of certain granitic rocks from their mineral contents. Expert Syst Appl 40:921–928

Yılmazkaya E (2007) Investigation of some factors affecting block production with diamond wire cutting method. M.Sc. Thesis, Hacettepe University, Turkey (in Turkish)

Yilmazkaya E, Ozcelik Y (2016) The effects of operational parameters on a mono-wire cutting system: efficiency in marble processing. Rock Mech Rock Eng 49:523–539

Yurdakul M, Gopalakrishnan K, Akdas H (2014) Prediction of specific cutting energy in natural stone cutting processes using the neuro-fuzzy methodology. Int J Rock Mech Min Sci 67:127–135

Zhan C, Gan A, Hadi M (2011) Prediction of lane clearance time of freeway incidents using the M5P tree algorithm. IEEE Trans Intell Transp Syst 12:1549–1557

Acknowledgements

This research has been done under full financial support of Isfahan University of Technology, Isfahan, Iran. The authors are grateful for all provided facilities.

Author information

Authors and Affiliations

Corresponding author

Appendix: Description of P-Wave Velocity and Grain Size

Appendix: Description of P-Wave Velocity and Grain Size

1.1 P-Wave Velocity

The Samples with approximate dimensions of 70 mm were provided from the block samples in the laboratory (Fig. 10). In the measurements, the PUNDIT Lab + and two transducers (a transmitter and a receiver) having a frequency of 54 kHz were used, described by ISRM (1981). The sample ends were cut parallel to each other and perpendicular to the long axis and smoothened. The two-transducer units were fixed to the smooth faces of the sample by applying grease, which ensured a tight contact between the transducers and the sample faces. The time needed for a longitudinal impulse was recorded in microseconds. The distance between the emitter and receiver was measured and recorded. The velocity was calculated from the ratio of travel distance to travel time of the P-wave through the sample. At least five measurements were taken from each rock type and average values were calculated (Vasconcelos et al. 2007).

1.2 Grain Size

The mineralogical composition and mean grain size of the samples were determined from thin sections using polarizing microscope and TS view software (Fig. 11).

Diameter equivalent or grain size (Gs) in each particle is obtained by Eq. (11) (Ghaysari et al. 2012). According to Eq. (12), the grain size for any sample is the average of grains size in tine sections.

where Dequi is diameter equivalent in term of mm, Ai represents area of grain (mm2), N is the number of tine sections, n represents the number of grain in any thin section and D is the same Dequi.

Rights and permissions

About this article

Cite this article

Almasi, S.N., Bagherpour, R., Mikaeil, R. et al. Predicting the Building Stone Cutting Rate Based on Rock Properties and Device Pullback Amperage in Quarries Using M5P Model Tree. Geotech Geol Eng 35, 1311–1326 (2017). https://doi.org/10.1007/s10706-017-0177-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10706-017-0177-0