Abstract

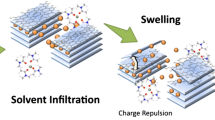

Regenerated cellulose (RC) film is an important cellulose-based product with a wide range of applications in the packaging industry and drug delivery. In this study, RC film was prepared using an organic electrolyte solution (OES)/ionic liquid (IL) system consisting of 1-ethyl-3-methylimidazolium acetate (EmimAc) and dimethyl sulfoxide (DMSO) to dissolve cotton linter at room temperature. Results showed that OES with EmimAc molar fraction in the range from 0.2 to 0.4 could rapidly dissolve cotton linter at room temperature, in contrast to 80 °C for EmimAc solution (control). The cellulose degradation was therefore much less than for the control, resulting in significant improvement in the mechanical properties and thermal stability of the RC film. In addition, the presence of DMSO significantly decreased the viscosity of the cellulose/OES system, being advantageous for casting of the RC film.

Similar content being viewed by others

References

Ali I (2012) Study of the mechanical behavior of recycled fibers. Applications to papers and paperboards. PhD thesis, Université Grenoble Alpes

Andanson J-M, Bordes E, Devémy J, Leroux F, Pádua AA, Gomes MFC (2014) Understanding the role of co-solvents in the dissolution of cellulose in ionic liquids. Green Chem 16:2528–2538

Bhatt BJ (2012) Regenerated cellulose for controlled oral drug delivery. PhD thesis, University of Iowa

Cao Y, Li H, Zhang Y, Zhang J, He J (2010) Structure and properties of novel regenerated cellulose films prepared from cornhusk cellulose in room temperature ionic liquids. J Appl Polym Sci 116:547–554

De Silva R, Vongsanga K, Wang X, Byrne N (2015) Cellulose regeneration in ionic liquids: factors controlling the degree of polymerisation. Cellulose 22:2845–2849

Duan C, Li J, Ma X, Chen C, Liu Y, Stavik J, Ni Y (2015) Comparison of acid sulfite (AS)-and prehydrolysis kraft (PHK)-based dissolving pulps. Cellulose 22:4017–4026

Gericke M, Schaller J, Liebert T, Fardim P, Meister F, Heinze T (2012) Studies on the tosylation of cellulose in mixtures of ionic liquids and a co-solvent. Carbohydr Polym 89:526–536

Härdelin L, Thunberg J, Perzon E, Westman G, Walkenström P, Gatenholm P (2012) Electrospinning of cellulose nanofibers from ionic liquids: the effect of different cosolvents. J Appl Polym Sci 125:1901–1909

Jayaramudu J, Reddy GSM, Varaprasad K, Sadiku E, Ray SS, Rajulu AV (2013) Preparation and properties of biodegradable films from Sterculia urens short fiber/cellulose green composites. Carbohydr Polym 93:622–627

Kim U-J, Eom SH, Wada M (2010) Thermal decomposition of native cellulose: influence on crystallite size. Polym Degrad Stab 95:778–781

Kljun A, Benians TA, Goubet F, Meulewaeter F, Knox JP, Blackburn RS (2011) Comparative analysis of crystallinity changes in cellulose I polymers using ATR-FTIR, X-ray diffraction, and carbohydrate-binding module probes. Biomacromolecules 12:4121–4126

Krässig HA (1993) Cellulose: structure, accessibility and reactivity, 1st edn. Gordon and Breach Science Publishers, Amsterdam, pp 6–12

Le KA, Rudaz C, Budtova T (2014) Phase diagram, solubility limit and hydrodynamic properties of cellulose in binary solvents with ionic liquid. Carbohydr Polym 105:237–243

Lee S-Y, Chun S-J, Kang I-A, Park J-Y (2009) Preparation of cellulose nanofibrils by high-pressure homogenizer and cellulose-based composite films. J Ind Eng 15:50–55

Liu Z, Wang H, Li Z, Lu X, Zhang X, Zhang S, Zhou K (2011) Characterization of the regenerated cellulose films in ionic liquids and rheological properties of the solutions. Mater Chem Phys 128:220–227

Liu X, Pang J, Zhang X, Wu Y, Sun R (2013) Regenerated cellulose film with enhanced tensile strength prepared with ionic liquid 1-ethyl-3-methylimidazolium acetate (EMIMAc). Cellulose 20:1391–1399

Mäki-Arvela P, Anugwom I, Virtanen P, Sjöholm R, Mikkola J-P (2010) Dissolution of lignocellulosic materials and its constituents using ionic liquids—a review. Ind Crops Prod 32:175–201

Mohamed MA, Salleh W, Jaafar J, Ismail A, Mutalib MA, Jamil SM (2015) Incorporation of N-doped TiO2 nanorods in regenerated cellulose thin films fabricated from recycled newspaper as a green portable photocatalyst. Carbohydr Polym 133:429–437

Nadhan AV, Rajulu AV, Li R, Jie C, Zhang L (2012) Properties of regenerated cellulose short fibers/cellulose green composite films. J Polym Environ 20:454–458

Nam S, French AD, Condon BD, Concha M (2016) Segal crystallinity index revisited by the simulation of X-ray diffraction patterns of cotton cellulose Iβ and cellulose II. Carbohydr Polym 135:1–9

Olsson C, Hedlund A, Idström A, Westman G (2014) Effect of methylimidazole on cellulose/ionic liquid solutions and regenerated material therefrom. J Mater Sci 49:3423–3433

Pang J, Liu X, Zhang X, Wu Y, Sun R (2013) Fabrication of cellulose film with enhanced mechanical properties in ionic liquid 1-allyl-3-methylimidaxolium chloride (AmimCl). Materials 6:1270–1284

Pang J, Wu M, Zhang Q, Tan X, Xu F, Zhang X, Sun R (2015) Comparison of physical properties of regenerated cellulose films fabricated with different cellulose feedstocks in ionic liquid. Carbohydr Polym 121:71–78

Poletto M, Zattera AJ, Forte MM, Santana RM (2012) Thermal decomposition of wood: influence of wood components and cellulose crystallite size. Bioresour Technol 109:148–153

Ramos J, Milano C, Romero V, Escalera S, Alba M, Vázquez M, Benavente J (2010) Water effect on physical–chemical and elastic parameters for a dense cellulose regenerated membrane: transport of different aqueous electrolyte solutions. J Membr Sci 352:153–159

Rinaldi R (2011) Instantaneous dissolution of cellulose in organic electrolyte solutions. Chem Commun 47:511–513

Robertson GL (2016) Food packaging: principles and practice. CRC Press, Boca Raton, pp 507–549

Sanla-Ead N, Jangchud A, Chonhenchob V, Suppakul P (2012) Antimicrobial activity of cinnamaldehyde and eugenol and their activity after incorporation into cellulose-based packaging films. Packag Technol Sci 25:7–17

SCAN (1998) SCAN-test standards. Viscosity in cupri-ethylenediamine (CED) solution. SCAN-CM 15:88. Scandinavian Pulp, Paper and Board Testing Committee, Stockholm

Segal L, Creely J, Martin A, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Shakeri A, Staiger M (2010) Phase transformations in regenerated microcrystalline cellulose following dissolution by an ionic liquid. BioResources 5:979–989

Soheilmoghaddam M, Wahit MU, Yussuf AA, Al-Saleh MA, Whye WT (2014) Characterization of bio regenerated cellulose/sepiolite nanocomposite films prepared via ionic liquid. Polym Test 33:121–130

Sun L, Chen JY, Jiang W, Lynch V (2015) Crystalline characteristics of cellulose fiber and film regenerated from ionic liquid solution. Carbohydr Polym 118:150–155

Sundberg J, Toriz G, Gatenholm P (2015) Effect of xylan content on mechanical properties in regenerated cellulose/xylan blend films from ionic liquid. Cellulose 22:1943–1953

Taheri H, Samyn P (2016) Effect of homogenization (microfluidization) process parameters in mechanical production of micro- and nanofibrillated cellulose on its rheological and morphological properties. Cellulose 23:1221–1238

Tian X-F, Fang Z, Jiang D, X-Y Sun (2011) Pretreatment of microcrystalline cellulose in organic electrolyte solutions for enzymatic hydrolysis. Biotechnol Biofuels 4:1

Ul-Islam M, Khattak WA, Ullah MW, Khan S, Park JK (2014) Synthesis of regenerated bacterial cellulose-zinc oxide nanocomposite films for biomedical applications. Cellulose 21:433–447

Wang S, Peng X, Zhong L, Jing S, Cao X, Lu F, Sun R (2015) Choline chloride/urea as an effective plasticizer for production of cellulose films. Carbohydr Polym 117:133–139

Wittmar A, Thierfeld H, Köcher S, Ulbricht M (2015) Routes towards catalytically active TiO2 doped porous cellulose. RSC Adv 5:35866–35873

Xie F, Zhong J, Liang H (2015) Reed cellulose dissolves in ionic liquid [Amim]Cl/co-solvent system. In: Manufacturing engineering and intelligent materials: proceedings of the 2015 international conference on manufacturing engineering and intelligent materials (ICMEIM 2015), Guangzhou, 30–31 January 2015, 2015. CRC Press, p 147

Xu A, Zhang Y, Zhao Y, Wang J (2013) Cellulose dissolution at ambient temperature: role of preferential solvation of cations of ionic liquids by a cosolvent. Carbohydr Polym 92:540–544

Xu A, Cao L, Wang B (2015) Facile cellulose dissolution without heating in [C4mim][CH3COO]/DMF solvent. Carbohydr Polym 125:249–254

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhao Y, Liu X, Wang J, Zhang S (2013) Insight into the cosolvent effect of cellulose dissolution in imidazolium-based ionic liquid systems. J Phys Chem B 117:9042–9049

Acknowledgments

The authors wish to acknowledge the financial support from the Tianjin Municipal Science and Technology Commission (grant no. 12ZCZDGX01100), the Canada Research Chair Program for funding, the China Scholarship Council (201508330154), the Natural Science Foundation of Zhejiang Province (LY17C160008), and the National Natural Science Foundation of China (21406208).

Author information

Authors and Affiliations

Corresponding authors

Additional information

In memory of Professor Huiren Hu (1947–2016), who devoted his life to his students at the Pulp and Paper program of the Tianjin University of Science and Technology, Tianjin, China.

Rights and permissions

About this article

Cite this article

Cheng, D., An, X., Zhang, J. et al. Facile preparation of regenerated cellulose film from cotton linter using organic electrolyte solution (OES). Cellulose 24, 1631–1639 (2017). https://doi.org/10.1007/s10570-017-1215-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1215-z