Abstract

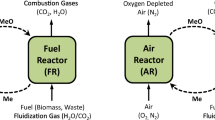

In this paper, the performances of two iron-based syngas-fueled chemical looping (SCL) systems for hydrogen (H2) and electricity production, with carbon dioxide (CO2) capture, using different reactor configurations were evaluated and compared. The first investigated system was based on a moving bed reactor configuration (SCL-MB) while the second used a fluidized bed reactor configuration (SCL-FB). Two modes of operation of the SCL systems were considered, namely, the H2 production mode, when H2 was the desired product from the system, and the combustion mode, when only electricity was produced. The SCL systems were modeled and simulated using Aspen Plus software. The results showed that the SCL system based on a moving bed reactor configuration is more efficient than the looping system with a fluidized bed reactor configuration. The H2 production efficiency of the SCL-MB system was 11 % points higher than that achieved in the SCL-FB system (55.1 % compared to 44.0 %). When configured to produce only electricity, the net electrical efficiency of the SCL-MB system was 1.4 % points higher than that of the SCL-FB system (39.9 % compared to 38.5 %). Further, the results showed that the two chemical looping systems could achieve >99 % carbon capture efficiency and emit ~2 kg CO2/MWh, which is significantly lower than the emission rate of conventional coal gasification-based plants for H2 and/or electricity generation with CO2 capture.

Similar content being viewed by others

Abbreviations

- AGR:

-

Acid gas removal

- AR:

-

Air reactor

- ASU:

-

Air separation unit

- CaL:

-

Calcium looping

- CCR:

-

Carbon capture rate (%)

- CGE:

-

Cold gas efficiency (%)

- CLC:

-

Chemical looping combustion

- FB:

-

Fluidized bed

- FR:

-

Fuel reactor

- HP:

-

High pressure

- HRSG:

-

Heat recovery steam generator

- IGCC:

-

Integrated gasification combined cycle

- IP:

-

Intermediate pressure

- LHV:

-

Lower heating value (MJ/kg)

- LP:

-

Low pressure

- MB:

-

Moving bed

- MDEA:

-

Methyldiethanolamine

- MEA:

-

Monoethanolamine

- OC:

-

Oxygen carrier

- PB:

-

Packed bed

- PC:

-

Pulverized coal

- PSA:

-

Pressure swing adsorption

- SCL:

-

Syngas chemical looping

- SE:

-

Specific emissions (kg/MWh)

- SR:

-

Steam reactor

- ST:

-

Steam turbine

- W:

-

Power (MW)

- \({\dot{m}}\) :

-

Mass flow rate (kg/s)

- ṅ :

-

Molar flow rate (kmol/s)

- η :

-

Efficiency (%)

- ar:

-

As received

- db:

-

Dry basis

References

Basavaraj RJ, Jayanti S (2015) Syngas-fueled, chemical-looping combustion-based power plant lay-out for clean energy generation. Clean Technol Envir 17(1):237–247. doi:10.1007/s10098-014-0781-0

Basavaraja RJ, Jayanti S (2015) Comparative analysis of four gas-fired, carbon capture-enabled power plant layouts. Clean Technol Envir 17(8):2143–2156. doi:10.1007/s10098-015-0936-7

CAESAR (2011) D 4.9 European best practice guidelines for assessment of CO2 capture technologies. Available from: http://caesar.ecn.nl/fileadmin/caesar/user/documents/D_4.9_best_practice_guide.pdf

Cebrucean D, Cebrucean V, Ionel I (2014) CO2 capture and storage from fossil fuel power plants. Energy Procedia 63:18–26. doi:10.1016/j.egypro.2014.11.003

Cho P, Mattisson T, Lyngfelt A (2004) Comparison of iron-, nickel-, copper- and manganese-based oxygen carriers for chemical-looping combustion. Fuel 83(9):1215–1225. doi:10.1016/j.fuel.2003.11.013

Cormos CC (2010) Evaluation of iron based chemical looping for hydrogen and electricity co-production by gasification process with carbon capture and storage. Int J Hydrogen Energy 35(6):2278–2289. doi:10.1016/j.ijhydene.2010.01.033

Cormos CC (2011a) Evaluation of power generation schemes based on hydrogen-fuelled combined cycle with carbon capture and storage (CCS). Int J Hydrogen Energy 36(5):3726–3738. doi:10.1016/j.ijhydene.2010.12.042

Cormos CC (2011b) Hydrogen production from fossil fuels with carbon capture and storage based on chemical looping systems. Int J Hydrogen Energy 36(10):5960–5971. doi:10.1016/j.ijhydene.2011.01.170

Cormos CC (2012) Evaluation of syngas-based chemical looping applications for hydrogen and power co-generation with CCS. Int J Hydrogen Energy 37(18):13371–13386. doi:10.1016/j.ijhydene.2012.06.090

Cormos CC, Cormos AM (2013) Assessment of calcium-based chemical looping options for gasification power plants. Int J Hydrogen Energy 38(5):2306–2317. doi:10.1016/j.ijhydene.2012.11.128

DYNAMIS (2007a) D 3.1.3 DYNAMIS CO2 quality recommendations. Available from: http://www.sintef.no/globalassets/project/dynamis-hypogen/publications/d3-1-3-dynamis-co2-quality-recommendations1.pdf

DYNAMIS (2007b) D 3.2.2 DYNAMIS H2 quality recommendations. Available from: http://www.sintef.no/globalassets/project/dynamis-hypogen/publications/d3-2-2-dynamis-h2-quality-recommendations1.pdf

Fan LS (2010) Chemical looping systems for fossil energy conversions. Wiley, Hoboken

Gnanapragasam NV, Reddy BV, Rosen MA (2009) Hydrogen production from coal using coal direct chemical looping and syngas chemical looping combustion systems: assessment of system operation and resource requirements. Int J Hydrogen Energy 34(6):2606–2615. doi:10.1016/j.ijhydene.2009.01.036

Gupta P, Velazquez-Vargas LG, Fan LS (2007) Syngas redox (SGR) process to produce hydrogen from coal derived syngas. Energy Fuel 21(5):2900–2908. doi:10.1021/ef060512k

Hamers HP, Romano MC, Spallina V, Chiesa P, Gallucci F, van Sint Annaland M (2014) Comparison on process efficiency for CLC of syngas operated in packed bed and fluidized bed reactors. Int J Greenh Gas Control 28:65–78. doi:10.1016/j.ijggc.2014.06.007

Henderson C (2010) Chemical looping combustion of coal. IEA Clean Coal Centre, CCC/178

Higman C, van der Burgt M (2008) Gasification, 2nd edn. Elsevier Inc, Burlington

Hossain MM, de Lasa HI (2008) Chemical-looping combustion (CLC) for inherent CO2 separations—a review. Chem Eng Sci 63(18):4433–4451. doi:10.1016/j.ces.2008.05.028

IEA (2010) Cost and performance of carbon dioxide capture from power generation. OECD/IEA. Available from: http://www.iea.org/publications/freepublications/publication/costperf_ccs_powergen.pdf

IEA (2012a) World energy outlook. OECD/IEA. Available from: http://www.iea.org/publications/freepublications/publication/WEO2012_free.pdf

IEA (2012b) Energy technology perspective 2012. Pathways to a clean energy system. OECD/IEA. Available from: http://www.iea.org/publications/freepublications/publication/ETP2012_free.pdf

IEA (2014a) Key world energy statistics. OECD/IEA. Available from: http://www.iea.org/publications/freepublications/publication/KeyWorld2014.pdf

IEA (2014b) CO2 emissions from fuel combustion. Highlights. OECD/IEA. Available from: http://www.iea.org/publications/freepublications/publication/CO2EmissionsFromFuelCombustionHighlights2014.pdf

IEAGHG (2007) Co-production of hydrogen and electricity by coal gasification with CO2 capture. Report 2007/13, September 2007. Available from: http://www.ieaghg.org/docs/General_Docs/Reports/2007-13%20Co-production%20of%20hydrogen%20and.pdf

IPCC (2014) Climate change 2014: Mitigation of climate change. Contribution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change. Cambridge University Press. Available from: http://www.ipcc.ch/pdf/assessment-report/ar5/wg3/ipcc_wg3_ar5_full.pdf

Jayanti S, Kareemulla D (2016) Detailed plant layout studies of oxy-enriched CO2 pulverized coal combustion-based power plant with CO2 enrichment. Clean Technol Environ. doi:10.1007/s10098-016-1125-z

Jerndal E, Mattisson T, Lyngfelt A (2006) Thermal analysis of chemical-looping combustion. Chem Eng Res Des 84(9):795–806. doi:10.1205/cherd05020

Li F, Kim HR, Sridhar D, Wang F, Zeng L, Chen J, Fan LS (2009) Syngas chemical looping gasification process: oxygen carrier particle selection and performance. Energ Fuel 23(8):4182–4189. doi:10.1021/ef900236x

Li F, Zeng L, Velazquez-Vargas LG, Yoscovits Z, Fan LS (2010) Syngas chemical looping gasification process: bench-scale studies and reactor simulations. AIChE J 56(8):2186–2199. doi:10.1002/aic.12093

Markewitz P, Kuckshinrichs W, Leitner W, Linssen J, Zapp P, Bongartz R, Schreiber A, Muller TE (2012) Worldwide innovations in the development of carbon capture technologies and the utilization of CO2. Energy Environ Sci 5(6):7281–7305. doi:10.1039/c2ee03403d

Mattisson T, Garcia-Labiano F, Kronberger B, Lyngfelt A, Adanez J, Hofbauer H (2007) Chemical-looping combustion using syngas as fuel. Int J Greenh Gas Control 1(2):158–169. doi:10.1016/s1750-5836(07)00023-0

Mukherjee S, Kumar P, Hosseini A, Yang A, Fennell P (2014) Comparative assessment of gasification based coal power plants with various CO2 capture technologies producing electricity and hydrogen. Energy Fuel 28(2):1028–1040. doi:10.1021/ef4024299

Mukherjee S, Kumar P, Yang A, Fennell P (2015) A systematic investigation of the performance of copper-, cobalt-, iron-, manganese- and nickel-based oxygen carriers for chemical looping combustion technology through simulation models. Chem Eng Sci 130:79–91. doi:10.1016/j.ces.2015.03.009

NETL (2013) Cost and performance baseline for fossil energy plants. Volume 1: Bituminous coal and natural gas to electricity. DOE/NETL-2010/1397, Revision 2a, September 2013. Available from: http://www.netl.doe.gov/File%20Library/Research/Energy%20Analysis/OE/BitBase_FinRep_Rev2a-3_20130919_1.pdf

Padurean A, Cormos CC, Cormos AM, Agachi PS (2011) Multicriterial analysis of post-combustion carbon dioxide capture using alkanolamines. Int J Greenh Gas Con 5(4):676–685. doi:10.1016/j.ijggc.2011.02.001

Prosser NM, Shah MM (2011) Current and future oxygen (O2) supply technologies for oxy-fuel combustion. In: Zheng L (ed) Oxy-fuel combustion for power generation and carbon dioxide (CO2) capture. Woodhead Publishing Limited, Cambridge, pp 195–227. doi:10.1533/9780857090980.2.195

Skorek-Osikowska A, Bartela L, Kotowicz J, Job M (2013) Thermodynamic and economic analysis of the different variants of a coal-fired, 460 MW power plant using oxy-combustion technology. Energy Convers Manag 76:109–120. doi:10.1016/j.enconman.2013.07.032

Sorgenfrei M, Tsatsaronis G (2014) Design and evaluation of an IGCC power plant using iron-based syngas chemical-looping (SCL) combustion. Appl Energy 113:1958–1964. doi:10.1016/j.apenergy.2013.03.089

Spallina V, Romano MC, Chiesa P, Gallucci F, van Sint Annaland M, Lozza G (2014) Integration of coal gasification and packed bed CLC for high efficiency and near-zero emission power generation. Int J Greenh Gas Control 27:28–41. doi:10.1016/j.ijggc.2014.04.029

Spliethoff H (2010) Power generation from solid fuels. Springer, Heidelberg. doi:10.1007/978-3-642-02856-4

Sridhar D, Tong A, Kim H, Zeng L, Li F, Fan LS (2012) Syngas chemical looping process: design and construction of a 25 kWth subpilot unit. Energy Fuel 26(4):2292–2302. doi:10.1021/ef202039y

Svoboda K, Slowinski G, Rogut J, Baxter D (2007) Thermodynamic possibilities and constraints for pure hydrogen production by iron based chemical looping process at lower temperatures. Energy Convers Manage 48(12):3063–3073. doi:10.1016/j.enconman.2007.05.019

Svoboda K, Siewiorek A, Baxter D, Rogut J, Pohorely M (2008) Thermodynamic possibilities and constraints for pure hydrogen production by a nickel and cobalt-based chemical looping process at lower temperatures. Energy Convers Manage 49(2):221–231. doi:10.1016/j.enconman.2007.06.036

Tong A, Sridhar D, Sun Z, Kim HR, Zeng L, Wang F, Wang D, Kathe MV, Luo S, Sun Y, Fan LS (2013) Continuous high purity hydrogen generation from a syngas chemical looping 25 kWth sub-pilot unit with 100 % carbon capture. Fuel 103:495–505. doi:10.1016/j.fuel.2012.06.088

Tong A, Bayham S, Kathe MV, Zeng L, Luo SW, Fan LS (2014) Iron-based syngas chemical looping process and coal-direct chemical looping process development at Ohio State University. Appl Energy 113:1836–1845. doi:10.1016/j.apenergy.2013.05.024

Urech J, Tock L, Harkin T, Hoadley A, Marechal F (2014) An assessment of different solvent-based capture technologies within an IGCC-CCS power plant. Energy 64:268–276. doi:10.1016/j.energy.2013.10.081

Xiang W, Chen S, Xue Z, Sun X (2010) Investigation of coal gasification hydrogen and electricity co-production plant with three-reactors chemical looping process. Int J Hydrogen Energy 35(16):8580–8591. doi:10.1016/j.ijhydene.2010.04.167

ZEP (2015) European Technology Platform for Zero Emission Fossil Fuel Power Plants. http://www.zeroemissionsplatform.eu. Accessed 17 Apr 2015

Acknowledgements

This work was partly carried out by the first author at the Institute for Energy Systems (Technical University of Munich) as part of his postdoctoral research program under the TUFF Grant. Second author would like to acknowledge the financial support through the strategic grant POSDRU107/1.5/S/77265 provided by the Ministry of Labor, Family and Social Protection (Romania), and co-financed by the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cebrucean, D., Cebrucean, V., Ionel, I. et al. Performance of two iron-based syngas-fueled chemical looping systems for hydrogen and/or electricity generation combined with carbon capture. Clean Techn Environ Policy 19, 451–470 (2017). https://doi.org/10.1007/s10098-016-1231-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1231-y