Abstract

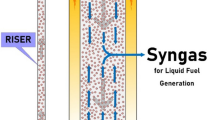

In this research, application of chemical looping combustion (CLC) instead of furnace in a conventional steam reformer (CSR) assisted by Pd/Ag membranes for hydrogen production has been analyzed. Ni- and Fe-based oxygen carriers have been employed in CLC for carbon dioxide capture. A steady state one dimensional heterogeneous catalytic reaction model is applied to analyze the performance and applicability of proposed CLC-SRM configuration via different oxygen carriers. Simulation results show that for all types of used oxygen carriers combustion efficiency reaches to 1 in the fuel reactor (FR) part of CLC-SRM. In CLC-SRM, methane conversion increases from 26% in CSR to 33.7% and 30.87 with employing Ni- and Fe- based oxygen carriers respectively. In addition, hydrogen production increases from 3380 kmol h–1 in CSR to 4258 and 3948 kmol h–1 in CLC-SRM with employing Ni- and Fe-based oxygen carriers respectively. Increasing FR feed temperature in CLC-SRM via all types of oxygen carriers shows enhancement of methane conversion and hydrogen production in the SR side. By increasing FR feed temperature from 800–1000 K, hydrogen production can increases 41.36 and 33.08% by using Ni- and Fe- based oxygen carriers in comparison with CSR respectively.

Similar content being viewed by others

References

Patcharavorachot, Y., Wasuleewan, M., Assabumrungrat, S., and Arpornwichanop, A, Analysis of hydrogen production from methane autothermal reformer with a dual catalyst-bed configuration, Theor. Found. Chem. Eng., 2012, vol. 46, no. 6, pp. 658–665.

Birol, F, World Energy Outlook 2006, Paris: International Energy Agency, 2006.

Climate change 2007: Synthesis Report, Geneva: IPCC, 2007.

Moghtaderi, B, Review of the recent chemical looping process developments for novel energy and fuel applications, Energy Fuels, 2012, vol. 26, no. 1, pp. 15–40.

Hossain, M. and de Lasa, H., Chemical-looping combustion (CLC) for inherent CO2 separation—a review, Chem. Eng. Sci., 2008, vol. 63, no. 18, pp. 4433–4451.

Adanez, J., Abad, A., Garcia-Labiano, F., Gayan, P., and de Diego, L.F., Progress in chemical-looping combustion and reforming technologies, Prog. Energy Combust. Sci., 2012, vol. 38, no.2, pp. 215–282.

Shuai, W., Guodong, L., Huilin, L., Juhui, C., Yurong, H., and Jiaxing, W, Fluid dynamic simulation in a chemical looping combustion with two interconnected fluidized beds, Fuel Process. Technol., 2011, vol. 92, no. 3, pp. 385–393.

Brahimi, D., Choi, J.H., Youn, P.S., Jeon, Y.W., Kim, S.D., and Ryu, H.J, Simulation on operating conditions of chemical looping combustion of methane in a continuous bubbling fluidized-bed process, Energy Fuels, 2012, vol. 26, no. 2, pp. 1441–1448.

Lyngfelt, A., Leckner, B., and Mattisson, T, A fluidized-bed combustion process with inherent CO2 separation–application of chemical-looping combustion, Chem. Eng. Sci., 2001, vol. 56, no. 10, pp. 3101–3113.

Dueso, C., Ortiz, M., Abad, A., García-Labiano, F., de Diego, L.F., Gayán, P., and Adánez, J., Reduction and oxidation kinetics of nickel-based oxygen-carriers for chemical-looping combustion and chemical-looping reforming, Chem. Eng. J., 2012, vol. 188, pp. 142–154.

Abad, A., Adánez, J., García-Labiano, F., de Diego, L.F., Gayán, P., and Celaya, J., Mapping of the range of operational conditions for Cu-, Fe-, and Ni-based oxygen carriers in chemical-looping combustion, Chem. Eng. Sci., 2007, vol. 62, nos. 1–2, pp. 533–549.

Rydén, M. and Arjmand, M, Continuous hydrogen production via the steam-iron reaction by chemical looping in a circulating fluidized-bed reactor, Int. J. Hydrogen Energy, 2012, vol. 37, no. 6, pp. 4843–4854.

Rydén, M. and Lyngfelt, A, Using steam reforming to produce hydrogen with carbon dioxide capture by chemical-looping combustion, Int. J. Hydrogen Energy, 2006, vol. 31, no. 10, pp. 1271–1283.

Ortiz, M., Gayán, P., de Diego, L.F., García-Labiano, F., Abad, A., Pans, M.A., and Adánez, J., Hydrogen production with CO2 capture by coupling steam reforming of methane and chemical-looping combustion: Use of an iron-based waste product as oxygen carrier burning a PSA tail gas, J. Power Sources, 2011, vol. 196, no. 9, pp. 4370–4381.

Chen, S., Shi, Q., Xue, Z., Sun, X., and Xiang, W, Experimental investigation of chemical-looping hydrogen generation using Al2O3 or TiO2-supported iron oxides in a batch fluidized bed, Int. J. Hydrogen Energy, 2011, vol. 36, no. 15, pp. 8915–8926.

Gayán, P., Pans, M.A., Ortiz, M., Abad, A., de Diego, L.F., García-Labiano, F., and Adánez, J., Testing of a highly reactive impregnated Fe2O3/Al2O3 oxygen carrier for a SR–CLC system in a continuous CLC unit, Fuel Process. Technol., 2012, vol. 96, pp. 37–47.

Go, K.S., Son, S.R., and Kim, S.D, Reaction kinetics of reduction and oxidation of metal oxides for hydrogen production, Int. J. Hydrogen Energy, 2008, vol. 33, no. 21, pp. 5986–5995.

De Diego, L.F., Ortiz, M., García-Labiano. F., Adánez, J., Abad, A., and Gayán, P., Hydrogen production by chemical-looping reforming in a circulating fluidized bed reactor using Ni-based oxygen carriers, J. Power Sources, 2009, vol. 192, no. 1, pp. 27–34.

Ortiz, M., Abad, A., de Diego, L.F., García-Labiano, F., Gayán, P., and Adánez, J., Optimization of hydrogen production by chemical-looping auto-thermal reforming working with Ni-based oxygen-carriers, Int. J. Hydrogen Energy, 2011, vol. 36, no. 16, pp. 9663–9672.

Zhang, X. and Jin, H, Thermodynamic analysis of chemical-looping hydrogen generation, Appl. Energy, 2013, vol. 112, pp. 800–807.

McGlashan, N.R, The thermodynamics of chemical looping combustion applied to the hydrogen economy, Int. J. Hydrogen Energy, 2010, vol. 35, no. 13, pp. 6465–6474.

Rahimpour, M.R., Hesami, M., Saidi, M., Jahanmiri, A., Farniaei, M., and Abbasi, M, Methane steam reforming thermally coupled with fuel combustion: Application of chemical looping concept as a novel technology, Energy Fuels, 2013, vol. 27, no. 4, pp. 2351–2362.

Ramaswamy, R.C., Ramachandran, P.A., and Dudukovíc, M.P, Recuperative coupling of exothermic and endothermic reactions, Chem. Eng. Sci., 2008, vol. 63, no. 6, pp. 165–167.

Abashar, M, Coupling of steam and dry reforming of methane in catalytic fluidized bed membrane reactors, Int. J. Hydrogen Energy, 2004, vol. 29, no. 8, pp. 799–808.

Abo-Ghander, N.S., Grace, J.R., Elnashaie, S.S.E.H., and Lim, C.J, Modeling of a novel membrane reactor to integrate dehydrogenation of ethyl benzene to styrene with hydrogenation of nitrobenzene to aniline, Chem. Eng. Sci., 2008, vol. 63, no. 7, pp. 1817–1826.

Rahimpour, M.R., Dehnavi, M.R., Allahgholipour, F., Iranshahi, D., and Jokar, S.M, Assessment and comparison of different catalytic coupling exothermic and endothermic reactions: A review, Appl. Energy, 2012, vol. 99, pp. 496–512.

Shigarov, A.B. and Kirillov, V.A, Modeling of membrane reactor for steam methane reforming: From granular to structured catalysts, Theor. Found. Chem. Eng., 2012, vol. 46, no. 2, pp. 97–107.

Barbieri, G., Shigarov, A.B., Meshcheryakov, V.D., and Kirillov, V.A, Use of Pd membranes in catalytic reactors for steam methane reforming for pure hydrogen production, Theor. Found. Chem. Eng., 2011, vol. 45, no. 5, pp. 595–609.

Xu, J. and Froment, G.F, Methane steam reforming, methanation and water-gas shift: I. Intrinsic kinetics, AIChE J., 1989, vol. 35, no. 1, pp. 88–96.

Xu, G., Li, P., and Rodrigues, A, Sorption enhanced reaction process with reactive regeneration, Chem. Eng. Sci., 2002, vol. 57, no. 18, pp. 3893–3908.

Cussler, E.L., Diffusion: Mass Transfer in Fluid Systems, Cambridge: Cambridge Univ. Press, 1984.

Wilke, C.R, Estimation of liquid diffusion coefficients, Chem. Eng. Prog., 1949, vol. 45, no. 3, pp. 218–224.

Reid, R.C., Sherwood, T.K., and Prausnitz, J., The Properties of Gases and Liquids, New York: McGrawHill, 1977, 3rd ed.

Smith, J.M., Chemical Engineering Kinetics, New York: McGraw-Hill, 1980.

Kunii, D. and Levenspiel, O, Fluidization Engineering, New York: Wiley, 1991.

Mori, S. and Wen, C.Y, Estimation of bubble diameter in gaseous fluidized beds, AIChE J., 1975, vol. 21, no. 1, pp. 109–115.

Sit, S.P. and Grace, J.R, Effect of bubble interaction on inter-phase mass transfer in gas fluidized beds, Chem. Eng. Sci., 1981, vol. 36, no. 2, pp. 327–335.

Author information

Authors and Affiliations

Corresponding author

Additional information

The article is published in the original.

Rights and permissions

About this article

Cite this article

Abbasi, M., Farniei, M., Rahimpour, M.R. et al. Hydrogen production in an environmental-friendly process by application of chemical looping combustion via Ni- and Fe-Based oxygen carriers. Theor Found Chem Eng 49, 884–900 (2015). https://doi.org/10.1134/S0040579515060019

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579515060019