Abstract

Seaweed supply chains in Indonesia, especially carrageenan and agar products, are subject to risks arising both inside the participating companies and in their external networks. Uncertainties in yield, quality, price, and infrastructure in one part of the supply chain can affect the whole chain. To ensure a sustainable seaweed industry, an appropriate supply chain risk management (SCRM) is needed. There are four critical steps in SCRM: identifying seaweed supply chains, identifying and categorizing risks, assessing risks, and mitigating risks. To identify seaweed supply chains, we conducted field research, in-depth interviews, and literature studies. The field survey was conducted in the Provinces of South Sulawesi, West Java, East Java, Banten, and West Nusa Tenggara. The seaweed supply chains were modeled by the software Umberto to get a better understanding of material and energy flows between the key members. To identify and categorize the risks, we started with the risks mentioned in the existing literature works, and then applied the Delphi method to analyze the potential risk sources, their causes, and their impacts. To assess risks, we used a semiquantitative approach through the face-to-face interviews to generate a risk map showing the likelihood, and impact of adverse events. Afterward, the risk intensity was categorized based on the value of the responses and classified into five categories: negligible, marginal, critical, most critical, and catastrophic risks. The mitigation strategies considered sustainability (environment, economy, and social) and risks criteria. Multi-criteria decision analysis was used to evaluate these strategies.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Because the use of marine biomass could circumvent many of the land and freshwater use issues associated with terrestrial biomass, much research on the farming and harvesting of marine biomass is being conducted. The tropical marine and coastal ecosystems are rich in biodiversity and represent some of the most productive resources for human life—including coral reefs, mangroves, sea-grass beds, sandy marine, and estuarine environments. As an archipelagic country with large areas for seaweed cultivation (11,109 km2), Indonesia is endowed with an abundance of tropical seaweed resources. The commercial types of red and brown seaweed can be widely found in Indonesia (see Fig. 1). The most important species of red seaweed for commercial products include Kappphycus alvarezii (Euchema cottonii/E.cottonii), Eucheuma dentilacum (E. spinosum), and Gracilaria. E.cottonii and E. Spinosum are utilized for the carrageenan industry, whereas Gracilaria is used in the agar industry.

The global demand for seaweed is expected to continue to increase in the coming years due to new food product developments using red algae. For instance, the use for dairy applications, frozen desserts, and ice cream grew at 5.5 % per year from 2006 to 2011 worldwide. Dairy products are currently the market leaders for high-value seaweed products, especially for those containing carrageenan. Pharmaceutical and household products are also driving growth in demand, but at a lower rate of about 2 % (CyberColloids Ltd. 2012). These additional demands for seaweed will challenge its supply chains, which are categorized as agri-food supply chains.

A seaweed supply chain in Indonesia consists of seaweed suppliers (seaweed farmers, local collectors, large traders, or exporters), manufacturers (carrageenan and agar companies), and customers (Mulyati 2015). Currently, these supply chains face four main uncertainties: First, volatility in dried seaweed availability can lead to downtime and the inability to meet customer timelines. Second, the volatility of seaweed prices (Fig. 2) strongly influences profitability, since price increases are difficult to pass on to the customer. Third, the quality fluctuations decrease customer satisfaction in the long term. Finally, the industry is vulnerable to external uncertainties, such as economic disruptions (e.g., the exchange rate crisis between the Indonesian Rupiah and the US Dollar) and natural and man-made disasters. The strong interdependencies of the supply chain parts and the supply chain participants makes risk management especially important for the seaweed industry in Indonesia and other producing countries.

Price of E. cottonii raw dried seaweed in 2014 (jasuda.net 2015)

Supply chain risk management has become an important multidisciplinary topic for researchers and professionals (Narasimhan and Talluri 2009), and both quantitative and qualitative studies have been published in many international journals and some monographs (Mulyati 2015). This topic integrates the three areas of supply chain management, risk management, and crisis management (Sodhi and Tang 2012). The majority of the papers on supply chain risk management focus on the theoretical framework as a platform for future research. According to Jüttner (2005), supply chain risk management is the identification and management of risks for the supply chain, through a coordinated approach among supply chain members, to reduce supply chain vulnerability as a whole. Tang (2006a, b) defines supply chain risk management similarly, as ‘the management of supply chain risks through coordination or collaboration among the supply chain partners so as to ensure profitability and continuity’.

Supply chains are becoming more dynamic. A supply chain consists of enterprise networks that experience turbulence continuously generating some potential risks (Pettit et al. 2010). Risk is based on the probability approach, defined as the probability and consequences of an adverse event. The consequences can be measured in terms of economic and environmental disturbances or loss of lives. The probability term based on the expert’s relative judgment as proposed by Benjamin et al. (2015a, b) was also adopted from Lindley (1985). The consequence term refers to the impact of disruptions to physical resources.

This increasing dynamism means that a comprehensive study of supply chain risk is necessary for early identification and assessment of potential risks in seaweed supply chains as well as mitigation of the risks. In addition, long-term solutions need to be prepared in Indonesia, which consider not only economic concerns but also environmental-, social-, and risk-related concerns.

In this work, we develop a reliable model for managing seaweed supply chain risks in Indonesia. The model provides managerial insight to decision makers in the seaweed supply chain and, in particular, to carrageenan and agar producers. It identifies and assesses seaweed supply chain risks and then offers appropriate mitigation strategies.

The paper is organized as follows: “Research Framework and Methods” section describes the research framework through quantitative approach, which includes identification of seaweed supply chain, and its risk assessment, and the applied methods . In “Seaweed Supply Chain in Indonesia” section the paper discusses specifically about the Indonesian seaweed supply chain. This paper then focuses on identification and categorization of the risk sources in “Identification and Categorization of Supply Chain Risks” section followed by the risk assessment that deals with the analysis of the probability of an event’s occurrence and an estimation of its consequences as described in “Risk Assessment for the Seaweed Supply Chain” section, which will then serve as a basis for developing a suitable alternative model of risk-mitigation strategies in a seaweed supply chain using multi-criteria decision analysis (MCDA) including the criteria covering different risk aspects (environmental, economic, and social) as well as providing the sustainable development in these areas as explained sin the next two sections: “Development of Risk Mitigation Strategies” and “Criteria for Risk Mitigations: Sustainability and Risk Criteria” sections.. Finally, this paper draws conclusions based on the results, highlighting also its contributions to the existing literature on supply chain risk management, especially for seaweed.

Research framework and methods

Many theoretical studies on supply chain risk management have been published (Christopher and Peck 2004; Jüttner et al. 2003; Khan and Burnes 2007; Sodhi and Tang 2012; Zsidisin and Ritchie 2009). In general, a supply chain risk analysis assesses the probability and impact of internal or external events that could negatively affect the supply chain and disturb the flow of goods, information, or finances (Kersten et al. 2006; Norrman and Jansson 2004; Pfohl et al. 2010; Zsidisin and Ritchie 2009). Supply chain risk management, in turn, uses strategies, techniques, and tools to manage risks along the supply chain so as to achieve supply chain sustainability through collaboration among the supply chain members.

Most papers offer mitigation strategies that seek to minimize supply chain risks in general; only a few offer guidance for specific risks. Some papers, however, do focus on how a company should respond to supply and demand risks (Demirel 2012; Mitchell 1995; Tomlin 2006; Wang et al. 2010; Zsidisin et al. 2004; Zsidisin et al. 2000). Flexible strategies are most commonly discussed by scholars as a way to mitigate risks in industrial supply chains (Sodhi and Tang 2012; Tang and Tomlin 2008). Some researchers also incorporate a decision model to determine the most appropriate mitigation method (Demirel 2012; Faisal et al. 2007; Wang 2014). Talluri et al. (2013) recommend assessing the mitigation strategies using the metric of sustainability, which seems particularly noteworthy in a discussion of risk-mitigation strategies for seaweed supply chains. From a variety of supply chain risk management processes available, we adopted the process suggested by Khan and Burnes (2007) and Sodhi and Tang (2012), because it is relatively simple and easy to apply.

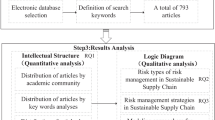

The four critical stages of supply chain risk management include (1) supply chain identification, (2) risk identification and categorization, (3) risk assessment, and (4) risk mitigation (see Fig. 3).

Supply chain identification pinpoints the primary and secondary members of a supply chain. This step illustrates the flows of material and energy, information, and finances.

Risk identification and categorization first finds the potential causes or sources of those risks at every significant link along the supply chain (Chapman et al. 2002) and then ranks them according to the extent and severity of their potential economic, environmental, financial, and social consequences.

Risk assessment has four functions: First, it helps decision makers allocate resources and prioritize different risk-mitigation strategies. Second, it supports management in focusing on the most critical risks. Third, it can be used as a program to meet legal or regulatory requirements. And fourth, it is used to develop contingency plans (Sodhi and Tang 2012). The risk assessment provides risk-related information in a quantitative and qualitative framework.

Risk mitigation involves strategies to decrease the likelihood and impact of risks. These strategies should help a supply chain to manage risks under normal conditions, as well as under abnormal circumstances or major disruptions. Thus, a supply chain with risk-mitigation strategies is made more resilient (Tang 2006a, b).

To identify the seaweed supply chains and possible risks, we conducted field research, in-depth interviews, and the literature studies. The field survey took place in the Provinces of South Sulawesi, West Java, East Java, Banten, and West Nusa Tenggara. Once the seaweed supply chains were identified, we modeled them using the software Umberto to get a better understanding of the material and energy flows between the key members. To identify and categorize the risks derived from the literature, we conducted several interviews and questionnaire surveys to analyze the potential risk sources, their causes, and their impacts. To assess risks, we used a semiquantitative approach through the face-to-face interviews to generate a risk map showing the likelihood and impact of adverse events. Afterward, the risk intensity was categorized based on the value of the response classified into five categories: negligible, marginal, critical, most critical, and catastrophic risks.

In a first step of risk identification, a questionnaire was designed based on an extensive review of possible supply chain risk sources and their operational definitions. The questionnaire itself contains questions on the causes and impacts of risks and was used for semistructured, face-to-face interviews with the respondents. The key respondents for identifying and categorizing seaweed supply chain risk were carrageenan companies (8 companies), agar companies (2 companies), large traders (3 companies), and seaweed farmers (2 farmers). They are located in South Sulawesi (Maros, Makassar, and Takalar), East Java (Pasuruan, Surabaya, and Sidoarjo), West Java (Bogor and Bekasi), Banten (Cilegon), and West Nusa Tenggara (Mataram). The information was also provided by seaweed experts from the Indonesian Institute of Science (LIPI) and Jaringan Sumber Daya (Jasuda), a Non-Governmental Organization (NGO) in South Sulawesi. All participants were top- level managers and included those in roles such as owners, directors, production managers and quality managers. On average, the respondents had worked in this position for 7 years and had been with their firm for 11 years. The first questionnaire was revised on the basis of comments from practitioners and experts. Following this step, their comments were incorporated into the final version of the questionnaire. Respondents were asked to indicate how their firms had been affected during the last 5 years (2009 to 2013) by supply chain disruptions.

The risk assessment was conducted in 2013 by semiquantitative analysis, in order to analyze the likelihood and impact of an event. The respondents from eight carrageenan and agar companies were asked to recall and estimate the frequency of adverse events. Afterward, the respondents were asked about the potential impacts of an incident. The companies are located in the province of South Sulawesi (2 companies), East Java (2 companies), West Java (2 companies), Banten (1 company), and West Nusa Tenggara (1 company). The respondents were directors (37.5 %), production and quality managers (37.5 %), and marketing managers (25 %). Most of the companies produce semirefined carrageenan and have all together assets totaling more than IDR 10 billion (about 1,1 million USD). The in-depth interviews were guided by a questionnaire in which each respondent was asked to mark the scale of probability and impacts of a risk source. The questionnaire was sent by e-mail prior to the face-to-face interview to help respondents better understand the content. The interviews took an average of 2 h.

Seaweed supply chain in Indonesia

This paper describes the application of the concept of risk management to the seaweed supply chain in Indonesia. For that purpose, first, the carrageenan and agar supply chains in Indonesia are analyzed (see Fig. 4). We found that seaweed supply chains having vertical collaboration consist of seaweed suppliers (farmers, local traders, large traders or exporters), seaweed manufacturers, carrageenan companies and agar companies. Previous studies of Indonesian seaweed supply chains described the members of seaweed supply chains including their activities. The authors presented the supply chains in a specific area, such as in Gorontalo Province (Neish 2007) and East Java Province (Wibowo 2011). In this paper, we investigated the Indonesian seaweed supply chain in general terms using the flows of material and energy from seaweed farmers to seaweed manufacturers. Our quantitative approach uses the Umberto software.

General structure of seaweed supply chain in Indonesia modeled by the Life Cycle Assessment software Umberto (Mulyati 2015)

Most seaweed farmers are independent and can sell their seaweed to local traders or wherever else they may want to sell it. Local traders play an essential role in the financial support of the farmers and provide critical technical information and market access. Most carrageenan and agar manufacturers are family businesses.

The material and energy flows within a seaweed supply chain were modeled using the Umberto software to get a better understanding of the relationships between the key members. The model also allows us to calculate raw materials requirements and production waste levels (see Fig. 4).

Seaweed farmers, local collectors, large traders or exporters, and seaweed manufactures are the primary members of a seaweed supply chain in Indonesia. Mulyati (2015) classified seaweed farmers, local collectors, and large traders into one group as seaweed suppliers. The five main activities of seaweed suppliers are cultivation, harvest, drying, storage, and distribution. Seaweed manufacturers obtain raw dried seaweed from large traders on a contract basis and process it into carrageenan or agar.

Local collectors and large traders can be representatives of seaweed manufacturers, independent companies, or cooperatives formed by seaweed farmers. Local traders help farmers sell seaweed to large traders, who eventually sell it to seaweed processors. Seaweed farmers and local traders have a very strong relationship with a high level of trust. The relationship between local and large traders is also quite strong, as the two parties regularly discuss the availability, quality, and price of seaweed. Large traders lend advanced financing to local traders so that they can buy seaweed from the farmers.

The flows of materials in agar and carrageenan supply chains are similar, especially in the suppliers’ activities. The difference in agar and carrageenan supply chains lies in the market absorption of raw dried seaweed. About 80 % of agar is consumed in the domestic market, whereas carrageenan is largely exported. In the Indonesian market, more than 60 % of the companies are carrageenan processing companies producing alkali-treated cottonii (ATC), semirefined carrageenan (SRC), and refined carrageenan; the remaining 40 % are agar companies. ATC is the simplest production process of carrageenan, resulting in chips, often called simply cottonii chips. SRC is dried alkali-treated cottonii chips, which can be milled to a variety of particle sizes, such as 40-60 mm, depending on the needs of the customer, and then sold as a powder. Semi-refined carrageenan (SRC) or processed Eucheuma seaweed (PES) is produced using the hot alkali method, and refined carrageenan is made by using the alcohol precipitation or gel-pressing method.

Identification and categorization of supply chain risks

Aven (2011) distinguished between risk, vulnerability, and resilience analysis. Risk is based on the probability approach, defined as the probability and consequences of an adverse event. Probability measures the level of confidence of an adverse event as a subjective probability. Vulnerability is ‘the manifestation of the inherent states of the system that can be subjected to a natural hazard or be exploited to adversely affect that system’. On the other hand, resilience is ‘the ability of the system to withstand a major disruption within acceptable degradation parameters and to recover within an acceptable time, and composite costs, and risks’ (Aven 2011, p. 515). Pettit et al. (2010) proposed supply chain resilience as a framework to provide management insights into strengths, weaknesses, and priorities.

Risk identification is the first step in determining possible sources of risk in a seaweed supply chain and refers to the recognition of sources of risk-hazard. It supports decision makers by bringing their attention to events that may cause disturbances to the supply chain (Norrman and Jansson 2004) Risk identification is a continuous process and continually seeks new risks as the basis for potential future work (Tchankova 2002).

A supply chain can be threatened by both internal and external risks. Internal risks can arise from coordination problems within the focal firm (process and control) and internal to the supply chain (supply and demand risks). Internal risks to the firm consist of process and control risks which happen in the seaweed manufacturers. Internal risks to the supply chain, but external risks to the firm consist of supply and demand risks. Supply risks often happen in the seaweed suppliers: farmers, local traders, and large traders. Demand risks are the risk sources from the external events but the risks are in the boundary system of a seaweed supply chain. More precisely, external risks are risks outside of companies and supply chains, which include also financial, policy and infrastructure risks. Most external risks, however, cannot be overcome by the firm or supply chain (Mulyati 2015). The framework of risk sources originally comes from Mason-Jones and Towill (1997).

During the interviews in our case study, we identified the sources of risks for the seaweed supply chain in Indonesia, which are summarized in Fig. 5. These risk sources are further investigated in the next step (risk assessment) for the marine products carrageenan and agar.

Risk assessment for the seaweed supply chain

Risk assessment is the critical step in risk management. Here, the probability of an event’s occurrence and an estimation of its consequences are estimated (Pettit et al. 2010). Kaplan and Garrick (1986) defined the terms risk, probability, and frequency in quantitative ways. Risk is “probability and consequence” (Kaplan and Garrick 1981, p. 13). It covers uncertainties and some form of loss or injury relative to the observer. Risk analysis answers three questions: What might happen? How likely is it to happen? And if it does happen, what are the consequences? Kaplan and Garrick (1981) also differentiate between probability and frequency. Probability can be measured and represents the numerical value of a state of knowledge, a degree of belief, or a level of significance (confidence). On the other hand, frequency is the result of an observation which it also can assess in a measurable number.

The risk sources of a seaweed supply chain are depicted in a risk map, which illustrates probabilities and impact using a seven-point Likert scale (Babbie 2007) (see Table 1). Probability is an essential part of the risk analysis. Aven and Reniers (2013) divided probability into two main categories, objective and subjective. Objective probabilities can be applied if the data and knowledge are available. Subjective (i.e., judgmental) probabilities are based on all sources of information–formal expert judgments, modeling, and Bayesian analysis. The authors recommend that probability in a risk analysis should be interpreted as a subjective probability referring to an uncertainty standard. Figure 6 shows the risk matrix depicting the frequency and impact of the risk sources in carrageenan supply chains in Indonesia.

Using the risk matrix, the risk intensity is categorized by multiplying probability and impact (Sodhi and Tang 2012). Tummala and Schoenherr (2011) divided risk intensity into five categories: negligible (values 1–10), marginal (11–20), critical (21–30), most critical (31–40), and catastrophic (41–49). In the following discussion, we comment on the derived risk matrix for carrageenan and agar supply chains. Figure 7 shows the Pareto chart, which illustrates the risk ranking. Based on their analysis of a poly-generation plant and bioenergy parks, Benjamin et al. (2015a, b) developed a criticality index to measure the relative impact of a unit’s failure within a system. Each unit can be ranked according to the index to specify the most critical component.

Figure 7 reveals, the most critical risk in a carrageenan supply chain is poor quality of raw dried seaweed (S4). Carrageenan companies often complain that they receive raw dried seaweed that does not comply with their standard requirements, such as an upper limit to moisture content of 35 %. Consequently, they buy the poor quality seaweed at a lower price, since they will have higher operating costs to clean it, for example, or to dry it to reach a moisture content of 30–32 %.

There are four main reasons for poor quality of raw dried seaweed. First, some farmers do not trouble themselves about good quality housekeeping. For example, they frequently harvest their seaweed after only 30 days, which results in lower carrageenan content and gel strength. In contrast, good quality seaweed is harvested after 40–45 days. Second, the majority of farmers dry their seaweed directly on the sand without using a protection pad. Thus, the seaweed is mixed with sand and other contaminants. Third, a lack of seaweed quality maintenance often leads to disease, particularly ice–ice. This disease commonly appears in E. cottonii types and causes whitened segments in nearly all of the seaweed branches. It is most prevalent during the seasonal change from the dry to the wet season and during the rainy season. (i.e., from May to August). Fourth, the quality of seaweed is also influenced by environmental conditions, such as water availability and quality during cultivation.

Other critical risks in the carrageenan supply chain are fluctuations in currency exchange rates (E2), scarcity of raw dried seaweed (S2), and uncertainty of seaweed yields (S3). Fluctuation of currency exchange rates is typically beyond the control of carrageenan companies, since it is influenced by the global economy.

The continuous development of new products containing carrageenan increases the demand for raw dried seaweed. Increases in supply, however, are hampered by seasonal change, disease, and a lack of capital available to farmers. The threat of scarcity puts pressure on short-term financial performance, whereas long-term scarcity can inhibit the growth of a company. Scarcity leads to higher prices, which causes focal companies to buy greater quantities of raw dried seaweed for their inventories when prices are lower. A focal company is a larger company with more working capital processing raw dried seaweed into carrageenan and agar. If raw dried seaweed is scarce, traders may buy at a higher price, even though the quality does not meet their requirements, in order to ensure some level of inventory. Volatile raw material prices are also caused by fluctuations in foreign demand, which often changes rapidly.

More than half the risks are categorized as marginal. These consist of machine breakdowns (P3), uncertain product price (D2), liquid waste negatively impacting the surrounding environment (E9), great distances between seaweed cultivation sites and producing company (S6), poor quality of carrageenan products (P4), inappropriate production scheduling (C2), lack of collaborative planning between focal companies and seaweed farmers (C3), delivery failure of raw dried seaweed (S5), demand volatility (D1), tax and legal regulations that do not support the development of the seaweed industry (regulatory variability (E1), disturbances to the electricity supply (E4), natural disasters: flood and earthquakes (E11), low product yields (P2), consumers switching to other carrageenan companies (D4), poor infrastructure between seaweed farmers and local and large traders (E3), disturbances to the water supply (E5), and low possibility to work in carrageenan manufacturing (E8).

Negligible risks are related to failures in chemical mixing (P1), the environmental impact of solid waste (E10), inadequate safety stocks (C1), and low acceptance from the community (E7). The findings shown in Fig. 8 have important implications for developing effective mitigation strategies.

Figure 8 shows the risk matrix for the agar supply chain. Here too, supply risk is a critical risk, a result consistent with those of other studies suggesting that supply risk is the most critical risk in the supply chain. Wagner and Bode (2008) stated that supply side risks have a significantly negative impact on supply chain performance. In contrast, the regulatory, legal, and bureaucratic risks, infrastructure risks, and catastrophic risks did not significantly affect supply chain performance.

The critical risks in the agar supply chain are uncertainty of seaweed yields (S3) and scarcity of Gracilaria (S2), as well as the negative impact of waste water on the environment (E8). Other risks are categorized as marginal or negligible.

Development of risk-mitigation strategies

The next step in supply chain risk management is to develop mitigation strategies that reduce the likelihood and impact of risks. These strategies should consider risk-based information to reduce network vulnerability (Benjamin et al. 2015a, b) and help manage risks under normal conditions, as well as under abnormal circumstances or major disruptions.

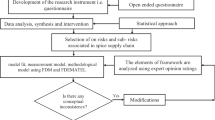

Methods from multi-criteria decision support can be applied to develop risk-mitigation strategies for the Indonesian seaweed supply chains. Three main steps can be differentiated: (1) problem identification and structuring, (2) model building and application of the model to inform and challenge thinking, and (3) determination of a plan of action (Belton and Stewart 2002). The first step starts with defining the strategic objective in order to develop a common understanding of the problem. An objective can be defined as ‘a statement of something that one desires to achieve’, and has three characteristics: a decision context, an object, and a direction of preference (Keeney 1992). For our purposes, the strategic objective is a sustainable seaweed supply chain that reduces risks.

To identify the relevant aspects of a sustainable seaweed supply chain, risk identification and categorization (“Seaweed Supply Chain in Indonesia” section) and risk assessment (“Identification and Categorization of Supply Chain Risks”section) are important prerequisites for deriving evaluation criteria. A criterion is ‘a particular perspective according to which decision alternatives may be compared, usually representing a particular interest, concern or point of view’ (Belton and Stewart 2002). According to Stewart (1992), criteria commonly have a hierarchical structure, starting from something general and leading to something specific. The purpose here is to break down the strategic objectives into measurable units (Bertsch 2008). The risk matrices (Figs. 6, 8) and Pareto charts (Figs. 7, 9) contain the relevant criteria, together with information about their weighting. Selecting criteria for the multi-criteria evaluation of risk-mitigation strategies for the seaweed supply chain in Indonesia is proposed in “Development of Risk Mitigation Strategies” section of this paper.

Alternatives are derived from the strategic objective and should be comparable to one another, that is, they should retain the same system boundaries and corresponding parameters. Moreover, they must be exclusive. That is, the decision makers can choose only one of the alternatives (Belton and Stewart 2002). For the development of risk-mitigation strategies for the seaweed supply chain in Indonesia, appropriate alternatives need to be formulated. Suitable expertise is required to derive solutions that are better than the status-quo.

After structuring a problem into a criteria hierarchy, it is necessary to investigate and calculate the values of the criteria for each alternative. Defining the value for each criterion is important for measuring the degree to which the overall objectives are met by these criteria (Keeney 1992). Once the problem identification and structuring is complete, the mathematical model building can start. For example, within the application of Multi-Attribute Utility Theory (MAUT)/multi-attribute value theory (MAVT), utility/value functions are applied. In contrast, the Preference Ranking Organization Method for Enrichment Evaluation (PROMETHEE) procedure makes use of preference functions (Belton and Stewart 2002; Geldermann and Rentz 2005). This makes it necessary to compile the method-specific information as utility or preference functions, with corresponding thresholds where needed. For the actual calculation with the chosen MCDA method, various software tools are available to help decision makers calculate the data from the decision table, utilizing criteria, values, and weights. Some methods require specific information for the preference functions, such as established parameters. It is important to clearly present and communicate the calculated result so that people from various disciplines can fully understand it. A visual display of data is commonly used in a user-friendly manner, typically with bar charts, pie charts, or trend lines (Eigner-Thiel et al. 2013). To analyze the stability of the result or important parameters, it is essential to conduct a sensitivity analysis. The impact of changes in the weight values assigned to criteria, for example, can be analyzed with such an analysis (Belton and Stewart 2002).

Based on the information obtained from the result and the sensitivity analysis, the decision maker should be able to make an informed decision and determine of a plan of action. In many important decisions, however, a group of decision makers is involved, and the viewpoints of various stakeholders must be considered (Lerche and Geldermann 2015). Moreover, the MCDA model is often used primarily to inform and challenge thinking. MCDA supports decision makers in integrating objective measurements with value judgments in order to make a more explicit decision and manage subjectivity. Subjectivity often occurs in the decision making process, especially when choosing the right criteria. Thus, expertise is needed to ensure effective decisions (Belton and Stewart 2002).

Criteria for risk mitigations: sustainability and risk criteria

Criteria are a basis for assessing alternative risk-mitigation strategies. A criteria hierarchy displays the top-down approach of starting with the overall objective and dividing it into smaller, more detailed targets. In this paper, the criteria should adequately cover environmental, economic, social, and risk aspects. The criteria hierarchy for risk-mitigation strategies in a seaweed supply chain in Indonesia is shown in Fig. 10.

A sustainable seaweed supply chain should incorporate the three principles of sustainable development: economic growth, environmental conservation, and social equality (the United Nations Conference on Environment and Development 1993). The term sustainability should be broken down into criteria that can be measured. Most of the sustainability targets and attributes in our case study are inspired by Eigner-Thiel et al. (2013). Environmental data are required to assess the impacts of seaweed manufacturing; economic data are needed to calculate the investment or duration of supply contracts; and social criteria are essential for determining how local people are engaged in terms of existence of the seaweed industry. Risk factors are also required to assess the possibility of an adverse event in a seaweed supply chain.

Environmental criteria cover waste water, solid waste, electricity consumption, and industrial land-use. Seaweed production requires a large amount of water for every step of the process. It can be assumed that the annual waste-water production (m3) is the same as the annual freshwater consumption. Solid waste is the annual waste from seaweed production and cultivation (metric tons). The seaweed industry depends on electric power to transform raw dried seaweed into a product. The criterion is the annual usage of electrical energy (MJ). Land-use refers to the area occupied by a seaweed manufacturing facility in square meters (m2). This area considers space for drying, processing, water availability, access to supply, and minimizing conflicts between food production and nature conservation.

Economic criteria include Net present value (NPV), length of supply contract, shared-revenue, and risk sharing. NPV is a financial indicator used to analyze the profitability of an investment for long-term assets. The NPV describes the net present value of all expected cash flows, both positive and negative. The formula for NPV is as follows:

where t represents any specific period, CF t indicates the cash flow at the end of the period, i represents the interest rate, and N is the number of periods comprising the economic life of the investment. Cash inflows are positive values of CF t and cash outflows are negative values of CF t . A positive NPV means that the investment is profitable, while a negative value indicates that the return is less than the cost of capital, so that the project should be rejected. If NPV equals zero, accepting or rejecting the project is an indifferent investment (Peterson Drake and Fabozzi 2010). In this study, the economic life of the project is 10 years, while the interest rate is calculated at 11 % in accordance with the Bank of Indonesia (2014). The higher the NPV, the better the result.

A supply contract is an agreement about the terms of the working relationship for the supply of raw materials between a seaweed supplier and a seaweed processor for a specific period of time. According to interviews with large traders, the maximum duration for a supply contract is 5 years, due to the relatively short lifecycle of seaweed. The classification of a supply contract’s duration is categorized into five groups: 1 point = 0–1 year, 2 points = 1–2 years, 3 points = 2–3 years, 4 points = 3–4 years, and 5 points = 4–5 years. The longer the contract between the suppliers and the operating company, the higher the operating company’s planning security (Eigner-Thiel et al. 2013).

Profit sharing can be a powerful driver for sustainability in a seaweed supply chain. If the suppliers (farmers) share in the profits, then the criterion is assessed positively (1). Otherwise, it is assessed negatively (0 points). Shared revenue is primarily created between the seaweed farmers and seaweed manufacturers. A relevant philosophy of supply chain risk, as identified by Jüttner (2005), is the willingness to accept joint risks. It is important to find out which risks are accepted as joint risks and which risks are to be borne by a specific supply chain member. This idea is also supported by Sodhi and Tang (2012), who recommend that decision makers spread the risks among the members of a supply chain. The criterion of risk sharing is assessed positively (1) if it is an option for supply chain members. Otherwise, if there is no possibility for risk sharing, it is assessed negatively (0 points).

Social criteria consist of collaborative decision making, creating job opportunities, and shared information. Collaborative decision making concerns the stakeholder communities’ participation as a horizontal collaboration in the seaweed industry’s development. A close and cooperative relationship is necessary between supply chain members and the local people. Stakeholders of the seaweed industry should be involved in the decision making process, which includes planning, implementing, monitoring, and evaluating supply chain activities. Frey (2006) suggested five levels of community linkage: networking, cooperation or alliance, coordination or partnership, coalition, and collaboration. The levels differ in their purpose, the structure of the decision making and the nature of leadership. The five levels of collaboration and their characteristics are described in Table 2. The stronger the collaboration, the better the overall planning process will be.

The social criterion of promoting job growth is of central importance in developing countries, where the goal is to alleviate poverty in the long run. The seaweed industry creates many full-time and part-time job opportunities, especially in coastal communities. These opportunities include the labors in seaweed farming, such as jobs in maintaining, harvesting, and drying seaweed. Labor is qualitatively measured and further divided into five categories: 1 = Very low level of work opportunities, 2 = Low level of work opportunities, 3 = Moderate level of work opportunities, 4 = High level of work opportunities, and 5 = Very high level of work opportunities. The greater the number of workers within the seaweed industry, the lower the unemployment rate will be. Providing information to the local population is the minimum level of collaboration (as in Table 2). Locals should be regularly informed through informational events or meetings about the workings of the seaweed industry, for example, what is being planned and what is expected to happen. For our assessment, one point is assigned for each participating group; If no outsiders are allowed to participate, the assigned value is zero. The more stakeholders are informed, the better (Eigner-Thiel et al. 2013).

Pfohl et al. (2010) found that companies within a supply chain should develop a common understanding of risks and agree on a risk evaluation standard. The criteria include risks in process, control, supply, demand, exchange rate, regulatory, and infrastructure. All are measured using qualitative values, in accordance with a seven-point scale. The scale indicates the risk frequency of an adverse event, where 1 = never (0 %), 2 = rarely (about 10 %), 3 = occasionally (about 30 %), 4 = sometimes (about 50 %), 5 = frequently (about 70 %), 6 = usually (about 90 %), and 7 = always (100 %) (Sodhi and Tang 2012). The higher the frequency of an event, the higher the risk of the supply chain.

The risk criteria are adverse events in process, control, supply, demand, exchange rate, regulatory oversight, and infrastructure. Process risk refers to risks resulting from the carrageenan and agar production processes.. These result from mistakes in chemical mixing, low quantity yields, machine breakdowns, and poor product quality. Control risks are caused by inadequate safety stock, discrepancies in production scheduling, and weaknesses in the collaborative planning between focal companies and seaweed suppliers. Supply risk refers to supplier activities or failures in inbound logistics. Sources of supply risk are fluctuations in raw dried seaweed, scarcity of raw dried seaweed, uncertain seaweed yields, low quality of raw dried seaweed, delivery failure of raw dried seaweed, and long distances between seaweed farmers and focal companies. Demand risk is any risks connected to the outbound logistics flow or downstream supply chain actions. It can stem from uncertainty in customer demands, price fluctuations, and a mismatch of demand forecasting. Exchange rate risk refers to financial disturbances as a result of monetary policies, interest rates, and political instability. Regulatory risk is associated with frequent changes in the laws and policies governing the seaweed industry. Infrastructure risk refers to disturbances in the water and electricity supplies that are necessary to support the seaweed industry.

The measurement scale for every criterion should be clearly determined, both in terms of a quantitative and a qualitative value (Georgopoulou et al. 1998). The unit of measurement for criteria consists of nominal, ordinal, interval, and ratio scales. Nominal scales include separating and classifying the objects to be measured into distinct categories and then calculating their values. Ordinal scales assign objects into classes, with the classes then being ranked with respect to one another (alternatively, the objects themselves can be ranked directly). Either the value or the consequence of selected criteria can affect the selection of the alternative (Belton and Stewart 2002). In the following section, we suggest some criteria measurements and provide a framework for managing supply chain risk, especially in seaweed supply chains. However, the results for each criterion in the specific study are not included in the scope of this paper. The provided criteria can be used for planning and developing risk mitigation, especially for seaweed supply chains.

Proposed alternative risk-mitigation strategies

According to the risk assessment, the supply risk in both the agar and carrageenan are most critical. The greatest risk in a carrageenan supply chain was poor quality of raw dried seaweed. In the agar supply chain, the critical risk was uncertainty of seaweed yields. The seaweed supply chain risks might be minimized by setting up a production plant close to cultivation areas. The advantages of building a company near seaweed sources are a shortened supply path, increased value added (particularly for seaweed farmers), and minimized handling and processing steps (Neish 2013).

Mulyati (2015) proposed three alternative for mitigating seaweed supply chain risks in Indonesia. The proposed strategies are building a small-scale seaweed processing facility owned by a group of farmers or a cooperative, building a large seaweed plant owned by a private company, and building a seaweed industrial cluster. To evaluate these strategies, she developed the hypothetical decision table and used the PROMETHEE for multi-criteria decision support, to demonstrate the basic procedure.

The first alternative strategy is building a small-scale seaweed processing facility owned by a group of farmers or a cooperative within the context of village norms and culture. Seaweed farmers, however, are categorized as small-scale entrepreneurs and, individually, do not have the working capital needed to set up a seaweed processing plant. Therefore, they have to form a group or a cooperative to effectively manage financial concerns and seaweed cultivation.

The second alternative is building a large-scale seaweed plant. The owner of a large company might be investors from either Indonesia or abroad. A seaweed industrial cluster is proposed as the third alternative. A cluster is ‘a geographic concentration of a specific industry, together with its supporting and related industries and service providers, including government and other institutions, such as universities and trade associations’ (Porter 1998). Cluster organizations are commonly a partnership between public and private institutions.

The proposed alternatives also support the idea of decentralization in Indonesia to different extents, primarily with respect to the way in which a local government regulates and manages its region. Decentralization policies have enabled seaweed farmers to interact more closely with government units. In the long run, the three alternative strategies could create job opportunities and alleviate poverty within Indonesia, especially in rural coastal areas.

Conclusions and outlook

Seaweed supply chains in Indonesia, especially those for carrageenan and agar products, are subject to risks from both inside their companies and from their external networks These risks include crop yield, quality, price, and supporting infrastructures. If there is a disturbance in one part of the supply chain, it can affect the whole chain. To ensure a sustainable seaweed industry, long-term planning is needed. Here, supply chain risk management (SCRM) can help. This paper describes and illustrates the steps of risk management in seaweed supply chains in Indonesia. The steps consist of determining the seaweed supply chains, identifying the risks, analyzing the risks, and developing mitigation strategies. Although these methods were illustrated for a particular case study, they should be applicable in other supply chains risk studies.

We found that the most critical risk for the carrageenan supply chain is poor quality of E.cottonii raw dried seaweed. The critical risks for the agar supply chain are yield uncertainty, the scarcity of Gracilaria raw dried seaweed, and the negative environmental impact of waste water. The development of risk-mitigation strategies could follow the general approach of multi-criteria decision making. Based on risk identification and assessment, decision criteria can be developed which stimulate the development of alternatives to the status quo of the supply chain management.

This research contributes to the existing knowledge of supply chain risks by providing an empirical and theoretical framework on the specific product of seaweed—an important marine biomass. It offers several noteworthy contributions for business administration in this industry in the form of supply chain risk management. This study can serve as a reference for the early detection of risks in a seaweed supply chain.

References

Aven T (2011) On some recent definitions and analysis frameworks for risk, vulnerability, and resilience. Risk Anal 31(4):515–522. doi:10.1111/j.1539-6924.2010.01528.x

Aven T, Reniers G (2013) How to define and interpret a probability in a risk and safety setting. Saf Sci 51(1):223–231. doi:10.1016/j.ssci.2012.06.005

Babbie ER (2007) The basics of social research. Recording for the Blind & Dyslexic, Princeton

Belton V, Stewart TJ (2002) Multiple criteria decision analysis: an integrated approach. Kluwer Academic Publishers, Boston

Benjamin MF, Tan RR, Razon LF (2015a) A methodology for criticality analysis in integrated energy systems. Clean Technol Environ Policy 17:935–946. doi:10.1007/s10098-014-0846-0

Benjamin MF, Tan RR, Razon LF (2015b) Probabilistic multi-disruption risk analysis in bioenergy parks via physical input-output modeling and analytic hierarchy process. Sustain Prod Consum 1:22–33. doi:10.1016/j.spc.2015.05.001

Bertsch V (2008) Uncertainty handling in multi attribute decision support for industrial risk management (Dissertation). Universität Karlsruhe. http://digbib.ubka.uni-karlsruhe.de/volltexte/1000007378

Chapman P, Christopher M, Jüttner U, Peck H, Wilding R (2002) Identfying and managing supply chain vulnerability. Logist Transp Focus 4(4): 59–70. http://eureka.bodleian.ox.ac.uk/id/eprint/1962

Christopher M, Peck H (2004) Building the resilient supply chain. Int J Logist Manag 15(2):1–14. doi:10.1108/09574090410700275

CyberColloids Ltd. (2012) Carrageenan Industry Report 2012. County Cook, Ireland. http://www.cybercolloids.net/downloads

Demirel S (2012) Strategic supply chain management with multiple products under supply and capacity uncertainty (Dissertation). The University of Michigan. http://deepblue.lib.umich.edu/bitstream/handle/2027.42/93917/sdemirel_1.pdf?sequence=1

Eigner-Thiel S, Schmehl M, Ibendorf J, Geldermann J (2013) Assessment of different bioenergy concepts in terms of sustainable development. In: Ruppert H, Kappas M, Ibendorf J (eds) Sustainable bioenergy production—an integrated approach. Springer, Dordrecht, pp 339–384

Faisal MN, Banwet DK, Shankar R (2007) Management of risk in supply chains: SCOR approach and analytical network process. Supply Chain Forum 8(2): 66–79. http://www.supplychain-forum.com/documents/articles/SCFvol8_2_2007_Faisal,%20Banwet%20%26%20Shankar.pdf

Frey BB (2006) Measuring collaboration among grant partners. Am J Eval 27(3):383–392. doi:10.1177/1098214006290356

Geldermann J, Rentz O (2005) Multi-criteria analysis for technique assessment: case study from industrial coating. J Ind Ecol 9(3):127–142. doi:10.1162/1088198054821591

Georgopoulou E, Sarafidis Y, Diakoulaki D (1998) Design and implementation of a group DSS for sustaining renewable energies exploitation. Eur J Oper Res 109(2):483–500. doi:10.1016/S0377-2217(98)00072-1

Jasuda.net. Information of seaweed price. http://www.jasuda.net/infopsr.php. Accessed 5 Aug 2015

Jüttner U (2005) Supply chain risk management. Int J Logist Manag 16(1):120–141. doi:10.1108/09574090510617385

Jüttner U, Peck H, Christopher M (2003) Supply chain risk management: outlining an agenda for future research. Int J Logist Res Appl 6(4):197–210. doi:10.1080/13675560310001627016

Kaplan S, Garrick BJ (1981) On the quantitative definition of risk. Risk Anal 1(1):11–27. doi:10.1111/j.1539-6924.1981.tb01350.x

Keeney RL (1992) Value-focused thinking: a path to creative decisionmaking. Harvard University Press, Cambridge

Kersten W, Böger M, Hohrath P, Späth H (2006) Supply chain risk management: development of a theoretical and empirical framework. In: Kersten W, Blecker T (eds) Operations and technology management, vol 1., Managing risks in supply chains. How to build reliable collaboration in logisticsErich Schmidt, Berlin, pp 3–18

Khan O, Burnes B (2007) Risk and supply chain management: creating a research agenda. Int J Logist Manag 18(2):197–216. doi:10.1108/09574090710816931

Lerche N, Geldermann J (2015) Integration of prospect theory into PROMETHEE - A case study concerning sustainable bioenergy concepts. Int J Multicriteria Decis Mak 5(4):309–333

Mason-Jones R, Towill DR (1997) Information enrichment: designing the supply chain for competitive advantage. Supply Chain Manag 2(4):137–148. doi:10.1108/13598549710191304

Mitchell V-W (1995) Organizational risk perception and reduction: a literature review. Br J Manag 6(2):115–133. doi:10.1111/j.1467-8551.1995.tb00089.x

Mulyati H (2015) Supply chain risk management study of the Indonesian Seaweed industry (Dissertation). University of Goettingen. https://ediss.uni-goettingen.de/handle/11858/00-1735-0000-0022-606A-8

Narasimhan R, Talluri S (2009) Perspectives on risk management in supply chains. Special Issue 27(2):114–118. doi:10.1016/j.jom.2009.02.001

Neish C (2007) Assessment of the seaweed value chain. USAID http://eiado.prevision.com.au/supplementary-reports/annotated-bibliography/assessment-seaweed-value-chain-indonesia

Neish IC (2013) Social and economic dimensions of carrageenan seaweed farming in Indonesia. In: Valderrama D, Cai J, Hishamunda N, Ridler NB (eds) FAO fisheries and aquaculture technical paper. Social and economic dimensions of carrageenan seaweed farming, vol 580. FAO, Rome, pp 61–89

Norrman A, Jansson U (2004) Ericsson’s proactive supply chain risk management approach after a serious sub-supplier accident. Int J Phys Distrib Logist Manag 34(5):434–456. doi:10.1108/09600030410545463

Peterson Drake P, Fabozzi FJ (2010) The basics of finance: an introduction to financial markets, business finance, and portfolio management., The Frank J. Fabozzi seriesWiley, Hoboken

Pettit TJ, Fiskel J, Croxton KL (2010) Ensuring supply chain resilience: development of a conceptual framework. J Bus Logist 31(1):1–21. doi:10.1002/j.2158-1592.2010.tb00125.x

Pfohl H-C, Köhler H, Thomas D (2010) State of the art in supply chain risk management research: empirical and conceptual findings and a roadmap for the implementation in practice. Logist Res 2(1):33–44. doi:10.1007/s12159-010-0023-8

Porter ME (1998) The competitive advantage of nations. The Free Press, New York

Sodhi MS, Tang CS (2012) Managing supply chain risk. International series in operations research & management science: v.172. Springer, New York

Stewart TJ (1992) A critical survey on the status of multiple criteria decision making theory and practice. Omega 20(5–6):569–586. doi:10.1016/0305-0483(92)90003-P

Talluri SS, Kull TJ, Yildiz H, Yoon J (2013) Assessing the efficiency of risk mitigation strategies in supply chains. J Bus Logist 34(4):253–269. doi:10.1111/jbl.12025

Tang CS (2006a) Robust strategies for mitigating supply chain disruptions. Int J Logist 9(1):33–45. doi:10.1080/13675560500405584

Tang CS (2006b) Perspectives in supply chain risk management. Int J Prod Econ 103(2):451–488. doi:10.1016/j.ijpe.2005.12.006

Tang C, Tomlin B (2008) The power of flexibility for mitigating supply chain risks. Int J Prod Econ 116(1):12–27. doi:10.1016/j.ijpe.2008.07.008

Tchankova L (2002) Risk identification—basic stage in risk management. Environ Manag Health 13(3):290–297. doi:10.1108/09566160210431088

The United Nations Conference on Environment and Development (1993) Agenda 21: Programme of action for sustainable development. Rio declaration on environment and development [u.a.]. United Nations Department of Public Information, New York

Tomlin B (2006) On the value of mitigation and contingency strategies for managing supply chain disruption risks. Manag Sci 52(5):639–657. doi:10.1287/mnsc.1060.0515

Tummala R, Schoenherr T (2011) Assessing and managing risks using the supply chain risk management process (SCRMP). Supp Chain Manag 16(6):474–483. doi:10.1108/13598541111171165

von Winterfeldt D, Edwards W (1986) Decision analysis and behavioral research. Cambridge University Press, Cambridge

Wagner SM, Bode C (2008) An empirical examination of supply chain performance along several deimensions of risk. J Bus Logist 29(1): 307–325. http://enterrasolutions.com/media/docs/2012/01/Wagner_Bode_2008_An_Empirical_Examination_of_Supply_Chain_Performance_Along_Several_Dimensions_of_Risk.pdf

Wang X (2014) An integrated fuzzy approach for the evaluation of supply chain risk mitigation strategies. Open J Soc Sci 02(09):161–166. doi:10.4236/jss.2014.29028

Wang Y, Gilland W, Tomlin B (2010) Mitigating supply risk: dual sourcing or process improvement? Manuf Serv Oper Manag 12(3):489–510

Wibowo Y (2011) The design of sustainable seaweed industry cluster development. Dissertation. Graduate School, Bogor Agricultural University. http://repository.ipb.ac.id/bitstream/handle/123456789/52735/BAB%20VII%20Simpulan%20dan%20Saranpdf?sequence=13

Zsidisin GA, Ritchie B (2009) Supply Chain Risk Management—Developments, Issues and Challenges. In Hillier FS, Zsidisin GA, Ritchie B (eds), International series in operations research & management scince. Supply Chain Risk. Springer, Boston, p 1–12

Zsidisin GA, Panelli A, Upton R (2000) Purchasing organization involvement in risk assessments, contingency plans, and risk management: an exploratory study. Supply Chain Manag 5(4):187–198. doi:10.1108/13598540010347307

Zsidisin GA, Ellram LM, Carter JR, Cavinato JL (2004) An analysis of supply risk assessment techniques. Int J Phys Distrib Logist Manag 34(5):397–413. doi:10.1108/09600030410545445

Acknowledgments

The authors gratefully acknowledge to the Japan Indonesia Presidential Scholarship (JIPS), the World Bank Institute for funding the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution-NonCommercial 4.0 International License (http://creativecommons.org/licenses/by-nc/4.0/), which permits any noncommercial use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Mulyati, H., Geldermann, J. Managing risks in the Indonesian seaweed supply chain. Clean Techn Environ Policy 19, 175–189 (2017). https://doi.org/10.1007/s10098-016-1219-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-016-1219-7