Abstract

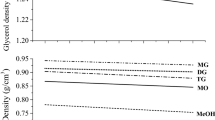

Biodiesel production could be economically sustainable if raw oils, i.e., waste cooking oil or oils with a high acid content, are used for its production. However, the high content of free fatty acid (FFA) of these oils makes necessary a pretreatment before the transesterification step. Esterification using methanol and a heterogeneous catalyst should be very convenient because this reaction permits to decrease FFA content by producing simultaneously methyl esters, i.e., biodiesel. This technology was applied in a continuous packed bed reactor for the deacidification of sunflower oil, using Amberlyst 46 as heterogeneous acid catalyst at pressure of 6 bar and temperature in the range of 54–95 °C. An amount of methanol five times greater than the stoichiometric was added to sunflower oil, in order to shift the reaction equilibrium but avoiding the formation of a double liquid phase. Two different kinetic models were considered: a pseudo-homogeneous and an adsorption based, which accounts for the different affinities toward the polymeric matrix of all the species involved in the reaction and the solvent (triglycerides). For both the models, either the ideal or non-ideal behavior of the mixture was considered, and the results were compared. The kinetic parameters of the esterification of free fatty acid were regressed using a robust mathematical model and using equilibrated resins, i.e., all the experiments started only after having let the catalyst adsorb reactants and products at the operative conditions.

Similar content being viewed by others

References

Berrios M, Siles J, Martìn MA, Martìn A (2007) A kinetic study of the esterification of free fatty acids (FFA) in sunflower oil. Fuel 86:2383–2388. doi:10.1016/j.fuel.2007.02.002

Bianchi CL, Boffito DC, Pirola C, Ragaini V (2009) Low temperature de-acidification process of animal fat as a pre-step to biodiesel production. Catal Lett 134:179–183. doi:10.1007/s10562-009-0228-0

Boffito DC, Pirola C, Bianchi CL (2012) Heterogeneous catalysis for free fatty acids esterification reaction as a first step towards biodiesel production. Chem Today 30:42–47

Buzzi-Ferraris G, Manenti F (2009) Kinetic models analysis. Chem Eng Sci 64:1061–1074

Buzzi-Ferraris G, Manenti F (2010a) Outlier detection in large data sets. Comput Chem Eng 35:388–390. doi:10.1016/j.compchemeng.2010.11.004

Buzzi-Ferraris G, Manenti F (2010b) A combination of parallel computing and object-oriented programming to improve optimizer robustness and efficiency. Comput Aid Chem Eng 28:337–342. doi:10.1016/S1570-7946(10)28057-4

Buzzi-Ferraris G, Manenti F (2012) BzzMath: library overview and recent advances in numerical methods. Comput Aid Chem Eng 30(2):1312–1326

Caetano NS, Silva VMS, Melo AC, Martins AA, Mata TM (2014) Spent coffee grounds for biodiesel production and other applications. Clean Technol Environ 16(7):1423–1430. doi:10.1007/s10098-014-0773-0

Chakrabarti A, Sharma MM (1993) Cationic ion-exchange resins as catalyst. React Polym 20:1–45. doi:10.1016/0923-1137(93)90064-M

Christoforous EA, Fokaides PA (2015) A review of quantification practices for plant-derived biomass potential. Int J Green Energy 12:368–378

Haas MJ, McAloon AJ, Yee WC, Foglia TA (2006) A process model to estimate biodiesel production costs. Bioresour Technol 97(4):671–678. doi:10.1016/j.biortech.2005.03.039

Iglinski B, Piechota G, Buczkowski R (2014) Development of biomass in polish energy sector: an overview. Clean Technol Environ. doi:10.1007/s10098-014-0820-x

Ilgen O (2014) Investigation of reaction parameters, kinetics and mechanism of oleic acid esterification with methanol by using Amberlyst 46 as a catalyst. Fuel Proc Technol 124:134–139. doi:10.1016/j.fuproc.2014.02.023

Liew WH, Hassim MH, Ng DKS (2014) Sustainability assessment for biodiesel production via fuzzy optimization during research and development (R&D) stage. Clean Technol Environ 16(7):1431–1444. doi:10.1007/s10098-014-0763-2

Lu X, Zhang Y, Yu Y, Ji J (2010) Deacidification and esterification of waste cooking oil: comparison of the coupled process with stand-alone catalytic esterification and extraction processes. Bioresources 5(1):147–158

Ma FR, Hanna MA (1999) Biodiesel production: a review. Bioresour Technol 70:1–15. doi:10.1016/S0960-8524(99)00025-5

Manenti F, Buzzi-Ferraris G (2009) Criteria for outliers detection in nonlinear regression problems. In: Jezowski J, Thullie J (eds) Comp Aid Chem Eng 913-917

Myint LL, El-Halwagi MM (2009) Process analysis and optimization of biodiesel production from soybean oil. Clean Technol Environ 11(3):263–276. doi:10.1007/s10098-008-0156-5

Ng J, Ng HK, Gan S (2010) Advances in biodiesel fuel for application in compression ignition engines. Clean Technol Environ 12(5):459–493. doi:10.1007/s10098-009-0268-6

Omota F, Dimian AC, Bliek A (2003) Fatty acid distillation by reactive distillation. Part 1: equilibrium based design. Chem Eng Sci 58:3175–3185. doi:10.1016/S0009-2509(03)00165-9

Pinto AC, Guariero LLN, Rezende MJC, Ribeiro NM, Torres EA, Lopes WA, Pereira PAP, Andrade JBJ (2005) Biodiesel: an overview. Braz Chem Soc 16B:1313–1330. doi:10.1590/S0103-50532005000800003

Pirola C, Bianchi CL, Boffito DC, Carvoli G, Ragaini V (2010) Vegetable oil deacidification by amberlyst: study of the catalyst lifetime and a suitable reactor configuration. Ind Eng Chem Res 49:4601–4606. doi:10.1021/ie901980c

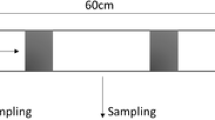

Pirola C, Galli F, Bianchi CL, Boffito DC, Comazzi A, Manenti F (2014a) Vegetable oil deacidification by methanol heterogeneously catalyzed esterification in (monophasic liquid)/solid batch and continuous reactors. Energy and Fuels (in press). doi:10.1021/ef501397h

Pirola C, Manenti F, Galli F, Bianchi CL, Boffito DC, Corbetta M (2014b) Heterogeneously catalyzed free fatty acids esterification in (monophasic liquid)/solid packed bed reactors (PBR). Chem Eng Trans 37:553–558. doi:10.3303/CET1437093

Popken T, Gotze L, Gmehling J (2000) Reaction Kinetics and chemical equilibrium of homogeneously and heterogeneously catalyzed acetic acid esterification with methanol and methyl acetate hydrolysis. Ind Eng Chem Res 39:2601–2611. doi:10.1021/ie000063q

Rehfinger A, Hoffmann U (1990) Kinetics of methyl tertiary butyl ether liquid phase synthesis catalyzed by ion exchange resin I. Intrinsic rate expression in liquid phase activities. Chem Eng Sci 45:1605–1612. doi:10.1016/0009-2509(90)80013-5

Santacesaria E, Tesser R, Di Serio M, Guida M, Gaetano D, Garcia A (2007) Kinetics and mass transfer of free fatty acids esterification with methanol in a tubular packed bed reactor: a key pretreatment in biodiesel production. Ind Eng Chem Res 46:5113–5121. doi:10.1021/ie061642j

Song W, Venimadhavan G, Manning JM, Malone MF, Doherty MF (1998) Measurement of residue curve maps and heterogeneous kinetics in methyl acetate synthesis. Ind Eng Chem Res 37:1917–1928. doi:10.1021/ie9708790

Tesser R, Di Serio M, Guida M, Nastasi M, Santacesaria E (2005) Kinetics of oleic acid esterification with methanol in the presence of triglycerides. Ind Eng Chem Res 44:7978–7982. doi:10.1021/ie050588o

Tesser R, Casale L, Verde D, Di Serio M, Santacesaria E (2009) Kinetics of free fatty acids esterification: batch and loop reactor modeling. Chem Eng J 154:25–33. doi:10.1016/j.cej.2009.03.010

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pirola, C., Galli, F., Corbetta, M. et al. Robust kinetic modeling of heterogeneously catalyzed free fatty acids esterification in monophasic liquid/solid packed bed reactor: rival model discrimination. Clean Techn Environ Policy 17, 1139–1147 (2015). https://doi.org/10.1007/s10098-015-0925-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-015-0925-x