Abstract

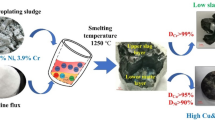

Sludges generated from electroplating wastewaters contain high concentrations of metals. Studies have confirmed that the concentrations of several metals in the sludge exceed that of those found in natural ores. A very good example is in the case of copper. The natural copper ore contains less than 1% of copper, whereas copper precipitate sludges from the electroplating industry may have an average of 5–10% of copper. Thus, they are one of the largest sources of untapped metal-bearing secondary materials amenable to metals recovery. In Malaysia, most of these metal-bearing sludges are disposed in specially engineering landfills, as many of them do not have the proper incentives and recovery technology. Very less metal recovery is being carried out, and there seems to be a huge waste in these valuable metal resources. With regards to that, an experimental study was carried out to develop and optimise a method of copper recovery from metal hydroxide sludges. Sludge samples containing high concentrations of copper were obtained from a local electroplating plant for the study. A procedure based upon mineral acid leaching or solubilisation was carried out. Two different types of acids, hydrochloric acid (HCl) and sulphuric acid (H2SO4) were used to compare the extractability of copper. Experiments were conducted at various acid concentrations and temperatures to determine the maximum amount of copper recoverable. From the results obtained, maximum copper (95%) was solubilised using H2SO4 of 10 M at temperature 110°C, for a leaching period of 4 h. These copper concentrated solutions were then heated and crystallised to form CuSO4 crystals. These crystals were then washed with water and purified. They can be then further treated and reutilised in the metallurgical industry. This study introduces a sustainable method of utilising an electroplating sludge containing valuable metals.

Similar content being viewed by others

References

Borchardt J, Redman W, Jones G, Sprague R (1980) Sludge and its ultimate disposal. Ann Arbor Science Publishers Inc., Michigan

Fikri MY (2003) Effects of metal hydroxide sludge addition in fired clay bricks. Master’s Thesis, University of Malaya, Malaysia

Lo KSL, Chen YH, (1990) Extracting heavy metals from municipal and industrial sludges. J Sci Total Environ 90:99–116

Oliver BG and Carey JH (1976) The removal and recovery of metals from sludge and incinerator ash. Ontario Ministry of the Environment Project no 74-3-15

Scott DS (1980) Extraction of metals from sewage sludge. Can J Chem Eng 58:673–677

Vesilind P, Spinosa L (2001) Sludge into biosolids: processing, disposal and utilization. IWA Publishing, London

Wallace R (1978) US Patent 4 082 546

Yeoh HK (1999) Study of electrodeposition of dilute heavy metal cations on glassy carbon using volummetric techniques. Master’s Thesis, University of Malaya, Malaysia

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sethu, V.S., Aziz, A.R. & Aroua, M.K. Recovery and reutilisation of copper from metal hydroxide sludges. Clean Techn Environ Policy 10, 131–136 (2008). https://doi.org/10.1007/s10098-007-0133-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-007-0133-4