Abstract

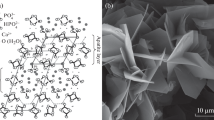

An attempt to maintain the three-dimensional space into restorative sites through the conveniently pack porous fillers are general used strategy. Advancement in the manufacturing protective shells in the scaffolds, which would be filled with brittle ceramic grafts for the development of highly connective pores provides the approach to solve crack problem for generating the tissues. Therefore, multilayered braided and alkalized poly(lactic acid) (PLA) composites with calcium phosphate bone cement (CPC) were synthesized and compared. The PLA/CPC composites were divided into various groups according to a series of heat-treatment temperatures (100–190 °C) and periods (1–3 h) and then characterized. The effects of 24-h immersion on the strength decay resistance of the samples were compared. Results showed that the residual oil capped on the surfaces of alkalized PLA braid was removed, and the structure was unaltered. However, the reduced tensile stress of alkalized PLA braids was due to ester-group formation by hydrolysis. Mechanical test results of PLA/CPC composites showed that the strength significantly increased after heat treatment, except when the heating temperature was higher than the PLA melting point at approximately 160–170 °C. The degree of PLA after recrystallization became higher than that of unheated composites, thereby leading to reduced strength and toughness of the specimen. Braiding fibers of biodegradable PLA reinforced and toughened the structure particularly of the extra-brittle material of thin-sheet CPC after implantation.

Similar content being viewed by others

References

Rechel B, Grundy E, Robine JM, Cylus J, Mackenbach JP, Knai C, McKee M. Ageing in the European Union. Lancet. 2013;381:1312–22.

Le Nihouannen D, Saffarzadeh A, Aguado E, Goyenvalle E, Gauthier O, Moreau F, Pilet P, Spaethe R, Daculsi G, Layrolle P. Osteogenic properties of calcium phosphate ceramics and fibrin glue based composites. J Mater Sci Mater Med. 2007;18:225–35.

Amini AR, Laurencin CT, Nukavarapu SP. Bone tissue engineering: recent advances and challenges. Crit Rev Biomed Eng. 2012;40:363–408.

Gunatillake PA, Adhikari R. Biodegradable synthetic polymers for tissue engineering. Eur Cell Mater. 2003;20:1–16.

Tayler MS, Daniels AU, Andriano KP, Heller J. Six bioabsorbale polymers: in vitro acute toxicity of accumulated degradation products. J Appl Biomater. 1994;5:151–7.

Lyu SP, Untereker D. Degradability of polymers for implantable biomedical devices. Int J Mol Sci. 2009;10:4033–65.

Pillai CKS, Sharma CP. Review paper: absorbable polymeric surgical sutures: chemistry, production, properties, biodegradability, and performance. J Biomater Appl. 2010;25:291–366.

Hartmann MH. High molecular weight polylactic acid polymers. In: Kaplan DL, editor. Biopolymers from renewable resources. Berlin: Springer; 1998. pp. 367–411.

Graves GA, Hentrich RL. Resorbable ceramic implants. J Biomed Muter Res Symp. 1972;2:91–115.

Khan AA, Vishwakarma SK, Bardia A, Venkateshwarulu J. Repopulation of decellularized whole organ scaffold using stem cells: an emerging technology for the development of neo-organ. J Artif Organs. 2014;17:291–300.

Yanoso-Scholl L, Jacobson JA, Bradica G, Lerner AL, O’Keefe RJ, Schwarz EM, Zuscik MJ, Awad HA. Evaluation of dense polylactic acid/beta-tricalcium phosphate scaffolds for bone tissue engineering. J Biomed Mater Res A. 2010;95A:717–26.

Lou CW, Yao CH, Chen YS, Hsieh TC, Lin JH, Hsing WH. Manufacturing and properties of PLA absorbable surgical suture. Text Res J. 2008;78:958–65.

Lou CW, Yao CH, Chen YS, Lu CT, Chen WC, Yen KC, Lin JH. PLA/β-TCP complex tubes: the mechanical properties and applications of artificial bone. J Biomater Sci Polym Ed. 2012;23:1701–12.

Lin JH, Hsieh CT, Hu JJ, Chen YS, Chen WC, Lou CW. Effect of heat-treated process on tensile property of PLA plied-yarn. Appl Mech Mater. 2012;184–185:963–6.

Ko CL, Chen JC, Tien YC, Hung CC, Wang JC, Chen WC. Biphasic products of dicalcium phosphate-rich cement with injectability and nondispersibility. Mater Sci Eng C Mater Biol Appl. 2014;37C:305–13.

Chen WC, Ju CP, Chern Lin JH. Variation in structure and properties of a non-dispersive TTCP/DCPA-derived CPC immersed in Hanks’ solution. J Oral Rehab. 2007;34:541–51.

Park JW, Lee DJ, Yoo ES, Im SS. Biodegradable polymer blends of poly(lactic acid) and starch. Korea Polym J. 1999;7:93–101.

Ko CL, Chen WC, Chen JC, Wu HY, Shih CJ, Tien YC, Hung CC, Wang JC. Properties of osteoconductive biomaterials: calcium phosphate cement with different ratios of platelet-rich plasma as identifiers. Mater Sci Eng C Mater Biol Appl. 2013;33:3537–44.

Ahmadi MS, Johari MS, Sadighi M, Esfandeh M. An experimental study on mechanical properties of GFRP braid-pultruded composite rods. eXPRESS Polym Lett. 2009;3:560–8.

Garlotta D. A literature review of poly(lactic acid). J Polym Environ. 2001;9:63–84.

Araque-Monrós MC, Vidaurre A, Luis GS, Bernabé SG, Manuel MP, Jorge ME. Study of the degradation of a new PLA braided biomaterial in buffer phosphate saline, basic and acid media, intended for the regeneration of tendons and ligaments. Polym Degrad Stabili. 2013;98:1563–70.

Zhu KJ, Hendren RW, Jensen K, Pitt CG. Synthesis, properties and biodegradation of poly(1,3-trimethylene carbonate). Macromolecules. 1991;24:1736–40.

Ayranci C, Carey J. 2D braided composites: a review for stiffness critical applications. Compos Struct. 2008;85:43–58.

Zhe Q, Xiaohui RF, Marco W, Michael M, Andreas S. The initial attachment and subsequent behavior regulation of osteoblasts by dental implant surface modification. J Biomed Mater Res A. 2007;82A:658–68.

Thomas M, Arora A, Katti DS. Surface hydrophilicity of PLGA fibers governs in vitro mineralization and osteogenic differentiation. Mater Sci Eng C Mater Biol Appl. 2014;45:320–32.

Ko CL, Chen JC, Tien YC, Hung CC, Wang JC, Chen WC. Osteoregenerative capacities of dicalcium phosphate-rich calcium phosphate bone cement. J Biomed Mater Res A. 2015;103A:203–10.

Klein CPAT, de Blieck-Hogervorst JMA, Wolke JGC, de Groot K. A study of solubility and surface features of different calcium phosphate coatings in vitro and in vivo: a pilot study. In: Vincenzini P, editor. Ceramics in substitutive and reconstructive surgery. Amsterdam: Elsevier; 1991. p. 363–73.

Wang Y, Von Euw S, Fernandes FM, Cassaignon S, Selmane M, Laurent G, Pehau-Arnaudet GÉR, Coelho C, Bonhomme-Coury L, Giraud-Guille MM, Babonneau F, Azaïs T, Nassif N. Water-mediated structuring of bone apatite. Nat Mater. 2013;12:1144–53.

Ko CL, Chang YY, Liou CH, Chen WC. Characterization of the aspects of osteoprogenitor cell interactions with physical tetracalcium phosphate anchorage on titanium implant surfaces. Mater Sci Eng C Mater Biol Appl. 2015;49C:7–13.

Cui W, Li X, Xie C, Zhuang H, Zhou S, Weng J. Hydroxyapatite nucleation and growth mechanism on electrospun fibers functionalized with different chemical groups and their combinations. Biomaterials. 2010;31:4620–9.

Guarino V, Causa F, Taddei P, di Foggia M, Ciapetti G, Martini D, Fagnano C, Baldini N, Ambrosio L. Polylactic acid fibre-reinforced polycaprolactone scaffolds for bone tissue engineering. Biomaterials. 2008;29:3662–70.

Guarino V, Ambrosio L. The synergic effect of polylactide fiber and calcium phosphate particle reinforcement in poly e-caprolactone-based composite scaffolds. Acta Biomater. 2008;4:1778–87.

Acknowledgments

The authors acknowledge the financial support provided by the Ministry of Science and Technology, Taiwan, under contract number MOST 102&103-2622-E-035-006-CC2 and MOST103-2221-E-035-099-.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

J.-H. Lin contributed equally.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, WC., Ko, CL., Yang, JK. et al. Comparison and preparation of multilayered polylactic acid fabric strengthen calcium phosphate-based bone substitutes for orthopedic applications. J Artif Organs 19, 70–79 (2016). https://doi.org/10.1007/s10047-015-0863-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10047-015-0863-8