Abstract

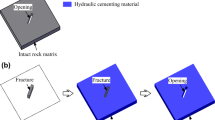

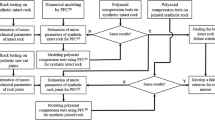

As jointed rocks consist of joints embedded within intact rock blocks, the presence and geometrical fabric of joints have a great influence on the mechanical behavior of rock. With consideration of the actual spatial shape of joints, a numerical model is proposed to investigate the fracture evolution mechanism of jointed rocks. In the proposed model, computerized tomography (CT) scanning is first used to capture the microstructure of a jointed sandstone specimen, which is artificially fabricated by loading the intact sample until the residual strength, and then digital image processing (DIP) techniques are applied to characterize the geometrical fabric of joints from the CT images. A simple vectorization method is used to convert the microstructure based on a cross-sectional image into a layer of 3-D vectorized microstructure and the overall 3-D model of the jointed sandstone including the real spatial shape of the joints is established by stacking the layers in a specific sequence. The 3-D model is then integrated into a well-established code [three-dimensional Rock Failure Process Analysis, (RFPA3D)]. Using the proposed model, a uniaxial compression test of the jointed sandstone is simulated. The results show that the presence of joints can produce tensile stress zones surrounding them, which result in the fracture of jointed rocks under a relatively small external load. In addition, the spatial shape of the joints has a great influence on the fracture process of jointed rocks.

Similar content being viewed by others

References

Argandoña RAR, Celorio C, Río LMS, Calleja L, Llavona J (1999) Characterization by computed X-ray tomography of the evolution of the pore structure of a dolomite rock during freeze–thaw cyclic tests. Phys Chem Earth 24:633–637

Bahaaddini M, Sharrock G, Hebblewhite BK (2013a) Numerical direct shear tests to model the shear behaviour of rock joints. Comput Geotech 51:101–115

Bahaaddini M, Sharrock G, Hebblewhite BK (2013b) Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression. Comput Geotech 49:206–225

Chen X, Bažant ZP (2014) Microplane damage model for jointed rock masses. Int J Numer Anal Meth Geomech 38(14):1431–1452

Cnudde V, Boone MN (2013) High-resolution X-ray computed tomography in geosciences: a review of the current technology and applications. Earth Sci Rev 123:1–17

Dai F, Wei MD, Xu NW, Ma Y, Yang DS (2015) Numerical Assessment of the Progressive Rock Fracture Mechanism of Cracked Chevron Notched Brazilian Disc Specimens. Rock Mech Rock Eng 48(2):463–479

Gonzalez RC, Woods RF (1992) Digital image processing. Addison-Wesley, Reading

Han YH, Hu DD, Matzar L (2014) Numerical computation of elastic properties for porous rocks based on CT-scanned images using direct mapping method. J Petrol Sci Eng 122:346–353

He L, An XM, Ma GW, Zhao ZY (2013a) Development of three-dimensional numerical manifold method for jointed rock slope stability analysis. Int J Rock Mech Mining Sci 64:22–35

He L, An XM, Zhao XB, Zhao ZY (2013b) Investigation on strength and stability of jointed rock mass using three-dimensional numerical manifold method. Int J Num Anal Meth Geomech 37(14):2348–2366

Ivars DM, Pierce ME, Darcel C, Juan RM, Potyondy DO, Young RP et al (2011) The synthetic rock mass approach for jointed rock mass modelling. Int J Rock Mech Min Sci 48(2):219–244

Jia P, Tang CA (2008) Numerical study on failure mechanism of tunnel in jointed rock mass. Tunn Undergr Space Technol 23(5):500–507

Jia P, Zhu W-C (2012) Dynamic-static coupling analysis on rockburst mechanism in jointed rock mass. J Central South Univ 19(11):3285–3290

Ketcham RA, Iturrino GJ (2005) Nondestructive high-resolution visualization and measurement of anisotropic effective porosity in complex lithologies using high resolution X-ray computed tomography. J Hydrol 302:92–106

Li LC, Tang CA, Li G, Wang SY, Liang ZZ, Zhang YB (2012) Numerical Simulation of 3D Hydraulic Fracturing Based on an Improved Flow-Stress-Damage Model and a Parallel FEM Technique. Rock Mech Rock Eng 45(5):801–818

Li B, Jiang YJ, Mizokami T, kusada K, Mitani Y (2014) Anisotropic shear behavior of closely jointed rock masses. Int J Rock Mech Min Sci 71:258–271

Liang ZZ, Tang CA, Li HX, Xu T, Zhang YB (2004) Numerical simulation of 3-d failure process in heterogeneous rocks. Int J Rock Mech Min Sci 41(S1):323–328

Liang ZZ, Xing H, Wang SY, Williams DJ, Tang CA (2012) A three-dimensional numerical investigation of the fracture of rock specimens containing a pre-existing surface flaw. Comput Geotech 45:19–33

Maghous S, Dormieux L, Kondo D, Shao JF (2013) Micromechanics approach to poroelastic behavior of a jointed rock. Int J Numer Anal Meth Geomech 37(2):111–129

Padmanabhan E, Sivapriya B, Huang KH, Askury AK, Chow WS (2015) The impact of stylolites and fractures in defining critical petrophysical and geomechanical properties of some carbonate rocks. Geomech Geophys Geo-energ Geo-resour. doi:10.1007/s40948-015-0007-x

Tang CA (1997) Numerical simulation of progressive rock failure and associated seismicity. Int J Rock Mech Min Sci 34(2):249–261

Tang CA, Wang SH, Fu YF (2003) Numerical tests on rock failure process. Science Press, Beijing (in Chinese)

Wang SY, Sloan SW, Tang CA (2014) Three-Dimensional Numerical Investigations of the Failure Mechanism of a Rock Disc with a Central or Eccentric Hole. Rock Mech Rock Eng 47(6):2117–2137

Wasantha PLP, Ranjith PG, Zhang QB, Tao Xu (2015) Do joint geometrical properties influence the fracturing behaviour of jointed rock? An investigation through joint orientation. J Geomech Geophysics for Geo Energy Geo Res. doi:10.1007/s40948-015-0001-3

Wei M, Dai F, Xu N, Xu Y, Xia K (2015) Three-dimensional numerical evaluation of the progressive fracture mechanism of cracked chevron notched semi-circular bend rock specimens. Eng Fract Mech 134:286–303

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Xu T, Ranjith PG, Wasantha PLP, Zhao J, Tang CA, Zhu WC (2013) Influence of the geometry of partially-spanning joints on mechanical properties of rock in uniaxial compression. Eng Geol 167:134–147

Xu NW, Dai F, Wei MD, Xu Y, Zhao T (2015) Numerical observation of three dimensional wing-cracking of cracked chevron notched Brazilian disc rock specimen subjected to mixed mode loading. Rock Mech Rock Eng. doi:10.1007/s00603-015-0736-8

Yang SQ, Huang YH (2014) Particle flow study on strength and meso-mechanism of Brazilian splitting test for jointed rock mass. Acta Mech Sin 30(4):547–558

Yang S-Q, Ranjith PG, Gui Y-L (2015a) Experimental study of mechanical behavior and x-ray micro ct observations of sandstone under conventional triaxial compression. Geotech Test J 38(2):178–197

Yang JP, Chen WZ, Yang DS, Yuan JQ (2015b) Numerical determination of strength and deformability of fractured rock mass by FEM modeling. Comput Geotech 64:20–31

Yun TS, Jeong YJ, Kim KY, Min KB (2013) Evaluation of rock anisotropy using 3D X-ray computed tomography. Eng Geol 163:11–19

Zhang HQ, Zhao ZY, Tang CA, Song L (2006) Numerical study of shear behavior of intermittent rock joints with different geometrical parameters. Int J Rock Mech Min Sci 43(5):802–816

Zhao GF, Russell AR, Zhao XB, Khalili N (2014) Strain rate dependency of uniaxial tensile strength in Gosford sandstone by the Distinct Lattice Spring Model with X-ray micro CT. Int J Solids Struct 51(7–8):1587–1600

Zhu WC, Tang CA (2004) Micromechanical model for simulating the fracture process of rock. Rock Mech Rock Eng 37(1):25–56

Acknowledgments

The present work is partially funded by the National Basic Research Program (“973 program”) of China (Grant No. 2013CB227902), the National Science Foundation of China (Grant Nos. 51222401, 51174045, 51474046, and 41272344), and the Fundamental Research Funds for the Central Universities (Grant Nos. N120401006, N110201001, and N120101001). This support is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, Q., Yang, S., Ranjith, P.G. et al. Numerical Modeling of Jointed Rock Under Compressive Loading Using X-ray Computerized Tomography. Rock Mech Rock Eng 49, 877–891 (2016). https://doi.org/10.1007/s00603-015-0800-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-015-0800-4