Abstract

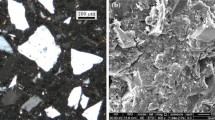

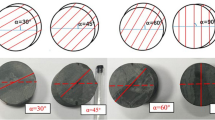

A discrete element method (DEM) called particle flow code (PFC2D) was used to construct a model for Brazilian disc splitting test in the present study. Based on the experimental results of intact Brazilian disc of rock-like material, a set of micro-parameters in PFC2D that reflected the macro-mechanical behavior of rock-like materials were obtained. And then PFC2D was used to simulate Brazilian splitting test for jointed rock mass specimens and specimen containing a central straight notch. The effect of joint angle and notch angle on the tensile strength and failure mode of jointed rock specimens was detailed analyzed. In order to reveal the meso-mechanical mechanism of crack coalescence, displacement trend lines were applied to analyze the displacement evolution during the crack initiation and propagation. The investigated conclusions can be described as follows. (1) The tensile strength of jointed rock mass disc specimen is dependent to the joint angle. As the joint angle increases, the tensile strength of jointed rock specimen takes on a nonlinear variance. (2) The tensile strength of jointed rock mass disc specimen containing a central straight notch distributes as a function of both joint angle and notch angle. (3) Three major failure modes, i.e., pure tensile failure, shear failure and mixed tension and shear failure mode are observed in jointed rock mass disc specimens under Brazilian test. (4) The notch angle and joint angle play important roles on crack initiation and propagation characteristics of jointed rock mass disc specimen containing a central straight notch under Brazilian test.

Similar content being viewed by others

References

ISRM: Suggested methods for determining tensile strength of rock materials. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts 15, 99–103(1978)

Jonsén, P., Häggblad, H.Å.: Fracture energy based constitutive models for tensile fracture of metal powder compacts. International Journal of Solids and Structures 44, 6398–6411 (2007)

Lanaro, F., Sato, T., Stephansson, O.: Microcrack modelling of Brazilian tensile tests with the boundary element method. International Journal of Rock Mechanics and Mining Sciences 46, 450–461 (2009)

Saksala, T., Hokka, M., Kuokkala, V.T., et al.: Numerical modeling and experimentation of dynamic Brazilian disc test on Kuru granite. International Journal of Rock Mechanics and Mining Sciences 59, 128–138 (2013)

Liu, Y.S., Fu, H.L., Rao, J.Y., et al.: Research on Brazilian disc splitting tests for anisotropy of slate under influence of different bedding orientation. Chinese Journal of Rock Mechanics and Engineering 31, 785–791 (2012) (in Chinese)

Liu, Y.S., Fu, H.L., Rao, J.Y., et al.: Tensile strength of slate based on Hoek-Brown criterion. Chinese Journal of Geotechnical Engineering 35, 1172–1177 (2013) (in Chinese)

Liu, Y.S., Fu, H.L., Wu, Y.M., et al.: Study on Brazilian splitting test for slate based on single weak plane theory. Journal of China coal society 38, 1775–1780 (2013) (in Chinese)

Cai, M., Kaiser, P.K.: Numerical simulation of the Brazilian test and the tensile strength of anisotropic rocks and rocks with pre-existing cracks. International Journal of Rock Mechanics and Mining Sciences 41, 478–483 (2004)

Tavallali, A., Vervoort, A.: Effect of layer orientation on the failure of layered sandstone under Brazilian test conditions. International journal of rock mechanics and mining sciences 47, 313–322 (2010)

Tavallali, A., Vervoort, A.: Behaviour of layered sandstone under Brazilian test conditions: Layer orientation and shape effects. Journal of Rock Mechanics and Geotechnical Engineering 5, 366–377 (2013)

Dan, D.Q., Konietzky, H., Herbst, M.: Brazilian tensile strength tests on some anisotropic rocks. International Journal of Rock Mechanics & Mining Sciences 58, 1–7 (2013)

Khanlari, G., Rafiei, B., Abdilor, Y.: An experimental investigation of the Brazilian tensile strength and failure patterns of laminated sandstones. Rock Mechanics and Rock Engineering (2014) DOI: 10.1007/s00603-014-0576-y

Cai, M.: Fracture initiation and propagation in a brazilian disc with a plane interface: A Numerical Study. Rock Mechanics and Rock Engineering 46, 289–302 (2013)

Krishnan, G.R., Zhao, X.L., Zaman, M., et al.: Fracture toughness of a soft sandstone. International Journal of Rock Mechanics and Mining Sciences 35, 695–710 (1998)

Al-Shayea, N.A., Khan, K., Abduljauwad, S.N.: Effects of confining pressure and temperature on mixed-mode (I–II) fracture toughness of a limestone rock. International Journal of Rock Mechanics and Mining Sciences 37, 629–643 (2000)

Al-Shayea, N.A.: Crack propagation trajectories for rocks under mixed mode I–II fracture. Engineering Geology 81, 84–97 (2005)

Ghazvinian, A., Nejati, H.R., Sarfarazi, V., et al.: Mixed mode crack propagation in low brittle rock-like materials. Arabian Journal of Geosciences 6, 4435–4444 (2013)

Dai, F., Wei, M.D., Xu, N.W., et al.: Numerical assessment of the progressive rock fracture mechanism of cracked chevron notched brazilian disc specimens. Rock Mechanics and Rock Engineering (2014) DOI: 10.1007/s00603-014-0587-8

Haeri, H., Shahriar, K., Marji, M.F., et al.: Experimental and numerical study of crack propagation and coalescence in precracked rock-like disks. International Journal of RockMechanics and Mining Sciences 67, 20–28 (2014)

Jiang, M., Shen, Z., Thornton, C.: Microscopic contact model of lunar regolith for high efficiency discrete element analyses. Computers and Geotechnics 54, 104–116 (2013)

Cundall, P.A., Strack, O.D.L.: A discrete numerical model for granular assemblies. Geotechnique 29, 47–65(1979)

Zhang, X.P., Wong, L.N.Y.: Cracking processes in rock-like material containing a single flaw under uniaxial compression: A numerical study based on parallel bonded-particle model approach. Rock Mechanics and Rock Engineering 45, 711–737 (2012)

Zhang, X.P., Wong, L.N.Y.: Crack initiation, propagation and coalescence in rock-like material containing two flaws: A numerical study based on bonded-particle model approach. Rock Mechanics and Rock Engineering 46, 1001–1021 (2013)

Ghazvinian, A., Sarfarazi, V., Schubert, W., et al.: A study of the failure mechanism of planar non-persistent open joints using PFC2D. Rock Mechanics and Rock Engineering 45, 677–693 (2012)

Sarfarazi, V., Ghazvinian, A., Schubert, W., et al.: Numerical Simulation of the Process of Fracture of Echelon Rock Joints. Rock Mechanics and Rock Engineering (2013) DOI: 10.1007/s00603-013-0450-3

Bewick, R.P., Kaiser, P.K., Bawden, W.F., et al.: DEM simulation of direct shear: 1. Rupture under constant normal stress boundary conditions. Rock Mechanics and Rock Engineering (2013) DOI: 10.1007/s00603-013-0490-8

Bewick, R.P., Kaiser, P.K., Bawden, W.F.: DEM simulation of direct shear: 2. Grain boundary and mineral grain strength component influence on shear rupture. Rock Mechanics and Rock Engineering (2013) DOI: 10.1007/s00603-013-0494-4

Itasca Consulting Group Inc.: Particle Flow Code. Sudbury: Itasca Consulting Group Inc (2004)

Kulatilake, P., Malama, B., Wang, J.: Physical and particle flow modeling of jointed rock block behavior under uniaxial loading. International Journal of Rock Mechanics and Mining Sciences 38, 641–657 (2001)

Park, J.W., Song, J.J.: Numerical simulation of a direct shear test on a rock joint using a bonded-particle model. International Journal of Rock Mechanics and Mining Sciences 46, 1315–1328 (2009)

Song, Y.L., Xia, C.C., Tang, Z.C., et al.: Numerical simulation and test validation for direct shear properties of rough joints under different contact states. Chinese Journal of Rock Mechanics and Engineering 32, 2028–2035 (2013) (in Chinese)

Lee, H., Jeon, S.: An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression. International Journal of Solids and Structures 48, 979–999 (2011)

Author information

Authors and Affiliations

Corresponding author

Additional information

The project was supported by the National Basic Research Program of China (2014CB046905), the Fundamental Research Funds for the Central Universities (China University of Mining and Technology) (2014YC10).

Rights and permissions

About this article

Cite this article

Yang, SQ., Huang, YH. Particle flow study on strength and meso-mechanism of Brazilian splitting test for jointed rock mass. Acta Mech Sin 30, 547–558 (2014). https://doi.org/10.1007/s10409-014-0076-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10409-014-0076-z