Abstract

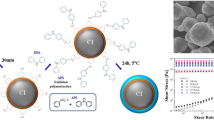

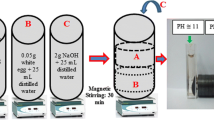

Core-shell structured soft magnetic carbonyl iron (CI) particles coated with poly(glycidyl methacrylate) were fabricated using a dispersion polymerization method. The surface of the CI particles was pretreated with 4-aminobenzoic acid to enhance the affinity between CI and poly(glycidyl methacrylate) (PGMA). The synthesized CI/PGMA core-shell particles were characterized by scanning electron microscopy, energy-dispersive X-ray spectroscopy, Fourier transform infrared spectroscopy, and vibrating sample magnetometry. The CI/PGMA particles were dispersed into a non-magnetic liquid for applications as a magnetorheological (MR) fluid, in which the rheological properties can be altered significantly by an external magnetic field. The MR suspension was analyzed using a rotational rheometer at various magnetic field strengths. Although the fabricated CI particles exhibited lower MR properties than pure CI particles, they showed improved dispersion stability according to the Turbiscan apparatus.

Similar content being viewed by others

References

Lopez-Lopez MT, Kuzhir P, Bossis G, Mingalyov P (2008) Preparation of well-dispersed magnetorheological fluids and effect of dispersion on their magnetorheological properties. Rheol Acta 47:787–796

Pu HT, Jiang FJ (2005) Towards high sedimentation stability: magnetorheological fluids based on CNT/Fe3O4 nanocomposites. Nanotechnology 16:1486–1489

Claracq J, Sarrazin J, Montfort JP (2004) Viscoelastic properties of magnetorheological fluids. Rheol Acta 43:38–49

Tang X, Zhang X, Tao R, Rong YM (2000) Structure-enhanced yield stress of magnetorheological fluids. J Appl Phys 87:2634–2638

de Vicente J, Lopez-Lopez MT, Duran JDG, Gonzalez-Caballero F (2004) Shear flow behavior of confined magnetorheological fluids at low magnetic field strengths. Rheol Acta 44:94–103

Hagenbuchle M, Liu J (1997) Chain formation and chain dynamics in a dilute magnetorheological fluid. Appl Opt 36:7664–7671

de Vicente J, Klingenberg DJ, Hidalgo-Alvarez R (2011) Magnetorheological fluids: a review. Soft Matter 7:3701–3710

Sung JH, Cho MS, Choi HJ, Jhon MS (2004) Electrorheology of semiconducting polymers. J Ind Eng Chem 10:1217–1229

Zhu XC, Jing XJ, Cheng L (2012) Magnetorheological fluid dampers: A review on structure design and analysis. J Intell Mater Syst Struct 23:839–873

Bica I, Liu YD, Choi HJ (2013) Physical characteristics of magnetorheological suspensions and their applications. J Ind Eng Chem 19:394–406

Shorey AB, Jacobs SD, Kordonski WI, Gans RF (2001) Experiments and observations regarding the mechanisms of glass removal in magnetorheological finishing. Appl Opt 40:20–33

Bombard AJF, Knobel M, Alcantara MR, Joekes I (2002) Evaluation of magnetorheological suspensions based on carbonyl iron powders. J Intell Mater Syst Struct 13:471–478

Ko SW, Lim JY, Park BJ, Yang MS, Choi HJ (2009) Magnetorheological carbonyl iron particles doubly wrapped with polymer and carbon nanotube. J Appl Phys 105: art. No. 07E703

Hayashi K, Sakamoto W, Yogo T (2013) One-pot synthesis of magnetic nanoparticles assembled on polysiloxane rod and their response to magnetic field. Colloid Polym Sci 291:2837–2842

Park BJ, Fang FF, Zhang K, Choi HJ (2010) Polymer-coated magnetic carbonyl iron microparticles and their magnetorheological characteristics. Korean J Chem Eng 27:716–722

Jiang WQ, Zhu H, Guo CY, Li JF, Xue Q, Feng JH, Gong XL (2010) Poly(methyl methacrylate)-coated carbonyl iron particles and their magnetorheological characteristics. Polym Int 59:879–883

Fang FF, Choi HJ, Jhon MS (2009) Magnetorheology of soft magnetic carbonyl iron suspension with single-walled carbon nanotube additive and its yield stress scaling function. Colloids Surf A 351:46–51

Zhang WL, Choi HJ (2012) Graphene oxide added carbonyl iron microsphere system and its magnetorheology under applied magnetic fields. J Appl Phys 111: art. No. 07E724

de Vicente J, Lopez-Lopez MT, Gonzalez-Caballero F, Duran JDG (2003) Rheological study of the stabilization of magnetizable colloidal suspensions by addition of silica nanoparticles. J Rheol 47:1093–1109

Liu YD, Choi HJ, Choi SB (2012) Controllable fabrication of silica encapsulated soft magnetic microspheres with enhanced oxidation-resistance and their rheology under magnetic field. Colloids Surf A 403:133–138

Bombard AJF, Knobel M, Alcantara MR (2007) Phosphate coating on the surface of carbonyl iron powder and its effect in magnetorheological suspensions. Int J Mod Phys B 21:4858–4867

Mrlik M, Sedlacik M, Pavlinek V, Bazant P, Saha P, Peer P, Filip P (2013) Synthesis and magnetorheological characteristics of ribbon-like, polypyrrole-coated carbonyl iron suspensions under oscillatory shear. J Appl Polym Sci 128:2977–2982

Kim IG, Kim JE, Liu YD, Choi HJ (2012) Polyamide Coated Soft Magnetic Microspheres and Their Magnetorheology. IEEE Trans Magn 48:3446–3449

Sedlacik M, Pavlinek V, Saha P, Svrcinova P, Filip P, Stejskal J (2010) Rheological properties of magnetorheological suspensions based on core-shell structured polyaniline-coated carbonyl iron particles. Smart Mater Struct 19: art No. 115008

Fang FF, Choi HJ (2007) Polymeric nanobead coated carbonyl iron particles and their magnetic property. Phys Status Solidi A 204:4190–4193

Kim SY, Kwon SH, Liu YD, Lee JS, You CY, Choi HJ (2014) Core-shell-structured cross-linked poly(glycidyl methacrylate)-coated carbonyl iron microspheres and their magnetorheology. J Mater Sci 49:1345–1352

Fang FF, Liu YD, Choi HJ, Seo Y (2011) Core-Shell Structured Carbonyl Iron Microspheres Prepared via Dual-Step Functionality Coatings and Their Magnetorheological Response. ACS Appl Mater Interfaces 3:3487–3495

Barbey R, Klok HA (2010) Room temperature, aqueous post-polymerization modification of glycidyl methacrylate-containing polymer brushes prepared via surface-initiated atom transfer radical polymerization. Langmuir 26:18219–18230

Zhou WW, Zhu JX, Cheng CW, Liu JP, Yang HP, Cong CX, Guan C, Jia XT, Fan HJ, Yan QY, Li CM, Yu T (2011) A general strategy toward graphene@metal oxide core-shell nanostructures for high-performance lithium storage. Energ Environ Sci 4:4954–4961

Shanmugharaj AM, Yoon JH, Yang WJ, Ryu SH (2013) Synthesis, characterization, and surface wettability properties of amine functionalized graphene oxide films with varying amine chain lengths. J Colloid Interface Sci 401:148–154

Rahman AU, Iqbal M, Rahman FU, Fu DY, Yaseen M, Lv YQ, Omer M, Garver M, Yang L, Tan TW (2012) Synthesis and characterization of reactive macroporous poly(glycidyl methacrylate-triallyl isocyanurate-ethylene glycol dimethacrylate) microspheres by suspension polymerization: Effect of synthesis variables on surface area and porosity. J Appl Polym Sci 124:915–926

Zhang WL, Piao SH, Choi HJ (2013) Facile and fast synthesis of polyaniline-coated poly(glycidyl methacrylate) core-shell microspheres and their electro-responsive characteristics. J Colloid Interface Sci 402:100–106

Shah K, Phu DX, Seong MS, Upadhyay RV, Choi SB (2014) A low sedimentation magnetorheological fluid based on platelike iron particles, and verification using a damper test. Smart Mater Struct 23: art. No. 027001

Chin BD, Park JH, Kwon MH, Park OO (2001) Rheological properties and dispersion stability of magnetorheological (MR) suspensions. Rheol Acta 40:211–219

de Vicente J, Ruiz-Lopez JA, Andablo-Reyes E, Segovia-Gutierrez JP, Hidalgo-Alvarez R (2011) Squeeze flow magnetorheology. J Rheol 55:753–779

Sari B, Yavas N, Makulogullari M, Erol O, Unal HI (2009) Synthesis, electrorheology and creep behavior of polyindole/polyethylene composites. React Funct Polym 69:808–815

Li WH, Du H, Guo NQ (2004) Dynamic behavior of MR suspensions at moderate flux densities. Mater Sci Eng A-Struct 371:9–15

Bell RC, Karli JO, Vavreck AN, Zimmerman DT, Ngatu GT, Wereley NM (2008) Magnetorheology of submicron diameter iron microwires dispersed in silicone oil. Smart Mater Struct 17: art. No. 015028

Hato MJ, Choi HJ, Sim HH, Park BO, Ray SS (2011) Magnetic carbonyl iron suspension with organoclay additive and its magnetorheological properties. Colloids Surf A 377:103–109

Li WH, Chen G, Yeo SH (1999) Viscoelastic properties of MR fluids. Smart Mater Struct 8:460–468

Li WH, Du HJ, Chen G, Yeo SH, Guo NQ (2003) Nonlinear viscoelastic properties of MR fluids under large-amplitude-oscillatory-shear. Rheol Acta 42:280–286

Buron H, Mengual O, Meunier G, Cayre I, Snabre P (2004) Optical characterization of concentrated dispersions: applications to laboratory analyses and on-line process monitoring and control. Polym Int 53:1205–1209

Acknowledgments

One of the authors (C. H. Hong) appreciates the financial support from Inha University, South Korea.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ahn, W.J., Jung, H.S., Kwon, S.H. et al. Effect of surface treatment on magnetorheological characteristics of core-shell structured soft magnetic carbonyl iron particles. Colloid Polym Sci 293, 2647–2654 (2015). https://doi.org/10.1007/s00396-015-3669-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00396-015-3669-6