Abstract

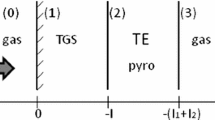

This article deals with the photopyroelectric (PPE) technique, a useful tool for optical spectroscopy and for measurement of thermal properties of condensed mater samples, in particular in the liquid state. It has been demonstrated here that, for constant laser power, the pyroelectric (PE) sensor response does not depend on the spatial distribution of the laser beam intensity. As a consequence of this, it follows that in the case of measurements in voltage mode, the signal amplitude is inversely proportional to the active area of the sensor. Then, if the active area is diminished, leaving the total area of the sensor constant, it is possible to increase the pyroelectric signal. On the basis of this result, a method is proposed to enhance the PPE signal measured in voltage mode by means of the optimization in the configuration of the sensor metal electrodes. It was experimentally demonstrated that using this improved technique, it is possible to increase up to ten times the amplitude of the signal without electrical noise rise.

Similar content being viewed by others

References

E. Marín (ed.), Thermal Wave Physics and Related Photothermal Techniques: Basic Principles and Recent Developments (Transworld Research Network, Kerala, 2009)

D. Dâdârlat, M. Chirtoc, C. Neamtu, R.M. Cândea, D. Bicanic Phys, Status. Solidi (a) 121, K231–K234 (1990)

Piezo Film Sensors—Technical Manual, http://www.meas-spec.com

J.W. Tester, M. Modell Thermodynamics and Its Applications (Prentice Hall International Series in the Physical and Chemical Engineering Sciences, New York 1999)

ISO 11146-2:2005(E), Lasers and laser-related equipment. Test methods for laser beam widths, divergence angles and beam propagation ratios. Part 2: General astigmatic beams. Available at: http://www.iso.org/iso/catalogue_detail.htm?csnumber=33626

J.D. Jackson Classical Electrodynamics (Wiley, London 1999)

R. Ivanov, E. Marin, I. Moreno, C. Araujo, J. Phys. D. Appl. Phys. 43, 225501–225506 (2010)

Acknowledgments

This work was supported by projects SIP-IPN 1491 and 20120226 and by SEP-CONACyT Grant 83289. The support from COFAA-IPN through the SIBE and PIFI Programs is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

1.1 A method for preparing an optimized sensor

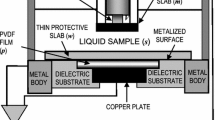

The shape of the PE can be anyone—round, square, etc. Let us consider the round example (Fig. 9). The central disc with two layers of metallization on both sides is prepared so that its diameter d (Fig. 9) is slightly larger than the diameter of the laser beam. Because the diameter of the central disk is almost the same as the laser beam diameter and the capacitance of the other areas of metal layers is minimal and negligible, the PE signal amplitude is maximal. For this reason the half-ring 1 (Fig. 5) where the electrodes are connected, may be of any shape and dimensions, thus facilitating the design of the cell. Additionally, if the width of the half-ring 2 (Fig. 5) is greater than 3μ, where μ is thermal diffusion length for minimal frequency, there will be no AC heat transfer from the sample and the PE, towards the cell body wall. The distance d between the ends of the two metallizations should be greater than 2 mm to ensure that no mutual capacitance exist between the peripheries of the two metal layers—the entire mutual capacitance is concentrated in the central disc. The metal layer surface between the edge of the central disc and the periphery of the PE is large. In this area the electrodes should be connected to supply PE voltage to the preamplifier. The large area assures a minimum contact resistance and makes the PE insensible to scratches and other damages during the operation.

Rights and permissions

About this article

Cite this article

Ivanov, R., Araujo, C., Martínez-Ordoñez, E.I. et al. Optimized configuration of the pyroelectric sensor metal electrodes in the photopyroelectric technique. Appl. Phys. B 110, 65–71 (2013). https://doi.org/10.1007/s00340-012-5252-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00340-012-5252-x