Abstract

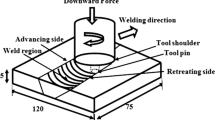

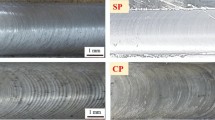

Five tools with different pin-tip profiles like thread taper, triangular, square, three grooves, and conical platform were designed to friction stir weld 20-mm-thick AA7075 alloy plates. The effects of pin-tip profiles on thermal cycles, material flow, and mechanical properties of the joints were studied. The results show that the temperature greatly decreases from the top to the bottom of the weld, and higher peak temperatures along the thickness are obtained using three grooves tool. Due to poor plastic flow reflected by local transfer behavior of material, thread taper and conical platform tools yield macro cross-sectional level pore defect on advancing side in nugget zone. However, triangular, square, and three grooves tools produce defect-free joints due to improving plastic flow resulted from stronger pulsating action and stirring power, leading to higher transfer displacements of local material. The tensile test results show that the joints fabricated by three grooves tool have better mechanical properties including strength and ductility owing to better material flow. A higher ultimate tensile strength of 391 ± 10 MPa, yield strength of 310 ± 12 MPa, and elongation of 8.3 % are obtained, respectively. This can be attributed to finer grains, greater natural aging response and optimum hardness.

Similar content being viewed by others

References

Bahemmat P, Haghpanahi M, BesharatiGivi M, Reshad Seighalani K (2012) Study on dissimilar friction stir butt welding of AA7075-O and AA2024-t4 considering the manufacturing limitation. Int J Adv Manuf Technol 59(9–12):939–953

Fuller CB, Mahoney MW, Calabrese M, Micona L (2010) Evolution of microstructure and mechanical properties in naturally aged 7050 And 7075 Al friction stir welds. Mater Sci Eng A 527:2233–2240

Sharma C, Dwivedi DK, Kumar P (2013) Effect of post weld heat treatments on microstructure and mechanical properties of friction stir welded joints of Al-Zn-Mg alloy AA7039. Mater Des 43:134–143

Aissani M, Gachi S, Boubenider F, Benkedda Y (2010) Design and optimization of friction stir welding tool. Mater Manuf Process 25(11):1199–1205

Feng AH, Chen DL, Ma ZY (2010) Microstructure and cyclic deformation behavior of a friction-stir-welded 7075 Al alloy. Metall Mater Trans A 41:957–971

Fu RD, Sun ZQ, Sun RC, Li Y, Liu HJ, Liu L (2011) Improvement of weld temperature distribution and mechanical properties of 7050 aluminum alloy butt joints by submerged friction stir welding. Mater Des 32:4825–4831

Singh R, Sharma C, Dwivedi D, Mehta N, Kumar P (2011) The microstructure and mechanical properties of friction stir welded Al–Zn–Mg alloy in as welded and heat treated conditions. Mater Des 32(2):682–687

Mao YQ, Ke LM, Liu FC, Huang CP, Chen YH, Liu Q (2015) Effect of welding parameters on microstructure and mechanical properties of friction stir welded joints of 2060 aluminum lithium alloy. Int J Adv Manuf Technol 81(5):1419–1431

Hu ZL, Wang XS, Pang Q, Huang F, Qin XP, Hua L (2015) The effect of postprocessing on tensile property and microstructure evolution of friction stir welding aluminum alloy joint. Mater Charact 99:180–187

Zhang F, Su XK, Chen ZY, Nie ZR (2015) Effect of welding parameters on microstructure and mechanical properties of friction stir welded joints of a super high strength Al–Zn–Mg–Cu aluminum alloy. Mater Des 67:483–491

Rodriguez RI, Jordon JB, Allison PG, Rushing T, Garcia L (2015) Microstructure and mechanical properties of dissimilar friction stir welding of 6061-to-7050 aluminum alloys. Mater Des 83:60–65

Mironov S, Masaki K, Sato YS, Kokawa H (2012) Relation between material flow and abnormal grain growth in friction-stir welds. Scripta Mater 67:983–986

Avettand Fenoel M, Taillard R (2015) Heterogeneity of the nugget microstructure in a thick 2050 Al friction-stirred weld. Metall Mater Trans A 46A:300–314

Canaday Clinton T, Moore Matthew A, Tang W, Reynolds AP (2013) Through thickness property variations in a thick plate AA7050 friction stir welded joint. Mater Sci Eng A 559:678–682

Xu WF, Liu JH, Luan GH, Dong CL (2009) Temperature evolution, microstructure and mechanical properties of friction stir welded thick 2219-O aluminum alloy joints. Mater Des 30:1886–1893

Srinivasa Rao T, Madhusudhan Reddy G, Koteswara Rao SR (2015) Microstructure and mechanical properties of friction stir welded AA7075-T651 aluminum alloy thick plates. Trans Nonferrous Met Soc China 25:1770–1778

Nandan R, Deb Roy T, Bhadeshia HKDH (2008) Recent advances in friction stir welding—process, weldment structure and properties. Progress Mater Sci 53:980–1023

Arora A, Debroy T, Bhadeshia HKDH (2011) Back-of-the-envelope calculations in friction stir welding—velocities, peak temperature, torque, and hardness. Acta Mater 59(5):2020–2028

Gratecap F, Racineux G, Marya S (2008) A simple methodology to define conical tool geometry and welding parameters in friction stir welding. Int J Mater Form 1:143–158

Kumar K, Kailas SV (2008) The role of friction stir welding tool on material flow and weld formation. Mater Sci Eng A 485:367–374

Thomas WM, Nicolash ED, Smith SD (2001) Friction stir welding—tool developments. In: Das SK, Kaufman JG, Lienert TJ, editors. Aluminium 2001 proceedings of the TMS 2001 aluminum automotive and joining session, TMS; 213–224

Zhang YN, Cao X, Larose S, Wanjara P (2012) Review of tools for friction stir welding and processing. Can Metall Quart 51(3):250–261

Thomas WM, Nicholas ED (1997) Friction stir welding for the transportation industries. Mater Des 18:269–273

Elangovan K, Balasubramanian V (2008) Influences of tool pin profile and tool shoulder diameter on the formation of friction stir processing zone in AA6061 aluminum alloy. Mater Des 29:362–373

Dawood HI, Mohammed KS, Rahmat A, Uday MB (2015) Effect of small tool pin profiles on microstructures and mechanical properties of 6061 aluminum alloy by friction stir welding. Trans Nonferrous Met Soc China 25:2856–2865

Khodaverdizadeh H, Heidarzadeh A, Saeid T (2013) Effect of tool pin profile on microstructure and mechanical properties of friction stir welded pure copper joints. Mater Des 45:265–270

Xu WF, Liu JH, Zhu HQ, Fu L (2013) Influence of welding parameters and tool pin profile on microstructure and mechanical properties along the thickness in a friction stir welded aluminum alloy. Mater Des 47:599–606

Mao YQ, Ke LM, Liu FC, Chen YH, Xing L (2015) Investigations on temperature distribution, microstructure evolution, and property variations along thickness in friction stir welded joints for thick AA7075-T6 plates. Int J Adv Manuf Technol. doi:10.1007/s00170-015-8182-z

Scialpi A, De Filippis LAC, Cavaliere P (2007) Influence of shoulder geometry on microstructure and mechanical properties of friction stir welded 6082 aluminum alloy. Mater Des 28:1124–1129

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng R 50:1–78

Mao YQ, Ke LM, Liu FC, Liu Q, Huang CP, Xing L (2014) Effect of tool pin eccentricity on microstructure and mechanical properties in friction stir welded 7075 aluminum alloy thick plate. Mater Des 62:334–343

Malarvizhi S, Balasubramanian V (2012) Influences of tool shoulder diameter to plate thickness ratio (D/T) on stir zone formation and tensile properties of friction stir welded dissimilar joints of AA6061 aluminumeAZ31B magnesium alloys. Mater Des 40:453–460

Ilangovan M, Rajendra Boopathy S, Balasubramanian V (2015) Effect of tool pin profile on microstructure and tensile properties of friction stir welded dissimilar AA6061-AA5086 aluminium alloy joints. Defence Technol 11:174–184

Zhang Z, Xiao BL, Wang D, Ma ZY (2011) Effect of alclad layer on material flow and defect formation in friction-stir-welded 2024 aluminum alloy. Metall Mater Trans A 42(6):1717–1726

Sato YS, Urata M, Kokawa H, Ikeda K (2003) Hall–Petch relationship in friction stir welds of equal channel angular-pressed aluminium alloys. Mater Sci Eng A 354:298–305

Su JQ, Nelson TW, Mishra R, Mahoney M (2003) Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater 51:713–729

Khodir SA, Shibayanagi T, Naka M (2006) Microstructure and mechanical properties of friction stir welded AA2024-T3 aluminum alloy. Mater Trans 47:185–193

Sharma C, Dwivedi DK, Kumar P (2013) Effect of welding parameters on microstructure and mechanical properties of friction stir welded joints of AA7039 aluminum alloy. Mater Des 36:379–390

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuqing, M., Liming, K., Fencheng, L. et al. Effect of tool pin-tip profiles on material flow and mechanical properties of friction stir welding thick AA7075-T6 alloy joints. Int J Adv Manuf Technol 88, 949–960 (2017). https://doi.org/10.1007/s00170-016-8882-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-016-8882-z