Abstract

In today’s manufacturing environment, the facility layout needs to be adaptable to changes. This situation requires the solution of the dynamic layout problem. But in previous studies of dynamic facility layout optimization, the main objective is to minimize the sum of the re-arrangement and material handling costs. To be more realistic, each of these cost terms in objective function might be of different importance to decision makers. In this research, the objective function has been considered as two distinct functions. This formulation enables decision makers to apply their own views. On the other hand, in the proposed model the adjacency-based objective aims at maximizing adjacency scores between the facilities in a facility layout has also been used. The proposed multi-objective model was defined as a complex combinatorial optimization problem. It has also been the objective of the present study to evaluate some of the known methods that have been proposed to solve the multi-objective problem. The results for test problems showed that the population based metaheuristic methods are useful tools in solving proposed model.

Similar content being viewed by others

References

Tompkins J, White J, Bozer Y, Tanchoco J (2003) Facilities planning, 3rd edn. Wiley, New Jersey

Tompkins J, White J (1984) Facilities planning. Wiley, New Jersey

Franke C, Basdere B, Ciupek M, Seliger S (2006) Remanufacturing of mobile phones—capacity, program and facility adaptation planning. Omega 34:562–570

Benjaafar S, Heragu SS, Irani SA (2000) Next generation factory layouts: research challenges and recent progress. I_FORMS 32(6):58–76

Şahin R, Ertogral K, Türkbey O (2010) A simulated annealing heuristic for the dynamic facility layout problem with budget constraint. Comput Ind Eng 59:308–313

McKendall JAR, Shang J, Kuppussamy S (2006) Simulated annealing heuristics for the dynamic facility layout problem. Comput Oper Res 33:2431–2444

Rosenblatt MJ (1986) The dynamics of plant layout. Manag Sci 32(1):76–86

Balakrishnan J, Cheng CH (1998) Dynamic layout algorithms: a state-of-the art survey. Omega 26(4):507–521

Kulturel-Konak S (2007) Approaches to uncertainties in facility layout problems: perspectives at the beginning of the 21st century. J Intell Manuf 18(2):273–284

Lacksonen TA, Enscore EE (1993) Quadratic assignment algorithms for the dynamic layout problem. Int J Prod Res 31(3):503–517

Urban TL (1993) A heuristic for the dynamic facility layout problem. IIE Trans 25(4):57–63

Conway DG, Venkataramanan MA (1994) Genetic search and the dynamic facility layout problem. Comput Oper Res 21(8):955–960

Kaku BK, Mazzola JB (1997) A tabu-search heuristic for the dynamic plant layout problem. Informs J Comput 9(4):374–384

McKendall ARJ, Liu WH (2012) New tabu search heuristics for the dynamic facility layout problem. Int J Prod Res 50:867–878

Rodriguez JM, MacPhee FC, Bonham DJ, Bhavsar VC (2006) Solving the dynamic plant layout problem using a new hybrid meta-heuristic algorithm. Int J High Performance Comput Netw 4(5/6):286–294

Baykasoglu A, Gindy NNZ (2001) A simulated annealing algorithm for dynamic layout problem. Comput Oper Res 28:1403–1426

McKendall JAR, Shang J (2006) Hybrid ant systems for the dynamic facility layout problem. Comput Oper Res 33:790–803

Erel E, Ghosh JB, Simon JT (2003) New heuristic for the dynamic layout problem. J Oper Res Soc 54:1275–1282

Krishnan KK, Cheraghi SH, Nayak CN (2006) Dynamic from-between chart: a new tool for solving dynamic facility layout problems. Int J Ind Syst Eng 1(1/2):182–200

Mazinani M, Abedzadeh M, Mohebali N (2012) Dynamic facility layout problem based on flexible bay structure and solving by genetic algorithm. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4229-6

Dunker T, Radons G, Westkamper E (2005) Combining evolutionary computation and dynamic programming for solving a dynamic facility layout problem. Eur J Oper Res 165(1):55–69

McKendall ARJ, Hakobyan A (2010) Heuristics for the dynamic facility layout problem with unequal-area departments. Eur J Oper Res 201(1):171–182

Jolai F, Tavkkoli R, Taghipour M (2012) A multi-objective particle swarm optimisation algorithm for unequal sized dynamic facility layout problem with pickup/drop-off locations. Int J Prod Res 50:4279–4293

Chen G, Rogers J (2009) Managing dynamic facility layout with multiple objectives. PICMET Proceeding, August 2–6, Portland, OR, USA

Urban TL (1987) A multiple criteria model for the facilities layout problem. Int J Prod Res 5(12):1805–1812

Lee KY, Roh MI, Jeong HS (2005) An improved genetic algorithm for multi-floor facility layout problems having inner structure walls and passages. Comput Oper Res 32:879–899

Lee HJ (1988) Heuristic graph-theoretic approach in facility layout problem: the development of a decision support system. Dissertation, University of Texas, Arlington, USA.

Deb K (2001) Multi objective using evolutionary algorithms. Wiley, LTD

Hisashi T, Hajime K, Shigenobu K (1996) Multi-objective optimisation by genetic algorithms: a review. Proceedings of the 3rd International Conference on Evolutionary Computation. 517–522.

Yang T, Chen MC, Hung CC (2007) Multiple attribute decision-making methods for the dynamic operator allocation problem. Math Comput Simul 73(5):285–299

Zadeh L (1963) Optimality and non-scalar-valued performance criteria. IEEE Trans Autom Control 8:59–60

Haimes YY, Lasdon LS, Wismer DA (1971) On a bicriterion formulation of the problems of integrated system identification and system optimization. IEEE Trans Syst Man Cyber 1(3):296–297

Deb K, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithme: NSGA-II. IEEE Trans Evol Comput 6(2):182–197

Jemai J, Zekri M, Mellouli K (2012) An NSGA-II algorithm for the green vehicle routing problem. Evolut Comp Comb Opt 7245:37–48

Bhattaacharya R, Bandyopadhyay S (2010) Solving conflicting bi-objective facility location problem by NSGA II evolutionary algorithm. Int J Adv Manuf Technol 51:397–414

Wei Z, Feng YX, Tan JR, Wang JL, Li ZK (2009) Multi-objective performance optimal design of large-scale injection molding machine. Int J Adv Manuf Technol 41:242–249

Storn R, Price K (1997) Differential evolution—a simple and efficient heuristic for global optimization over continuous spaces. J Glob Optim 11:241–354

Nearchou AC (2006) Meta-heuristics from nature for the loop layout design problem. Int J Prod Econ 101:312–328

Yanmei H, Minghao Y, Xiangtao L (2011) A novel objective function for job-shop scheduling problem with fuzzy processing time and fuzzy due date using differential evolution algorithm. Int J Adv Manuf Technol 56(9–12):1125–1138

Yang SH, Natarajan U, Sekar M, Palani S (2010) Prediction of surface roughness in turning operations by computer vision using neural network trained by differential evolution algorithm. Int J Adv Manuf Technol 51:965–971

Dexuan Z, Haikuan L, Liqun G, Steven L (2011) An improved differential evolution algorithm for the task assignment problem. Eng Appl Artif Intell 24:616–624

Czyzak P, Jaszkiewicz A (1998) Pareto simulated annealing—a metaheuristic technique for multipleobjective combinatorial optimization. J Mul Cri Dec An 7(1):34–47

Drexl A, Nikulin Y (2008) Multicriteria airport gate assignment and Pareto simulated annealing. IIE Trans 40:385–397

Amany MM, Hisham MA (2012) Optimal composition of virtual enterprises with interval cost parameters. The 8th International Conference on INFOrmatics and Systems, May 14–16.

Zitzler E, Thiele L (1999) Multiobjective evolutionary algorithms: a comparative case study and the strength Pareto approach. IEEE Trans Evol Comput 3:257–271

Schott JR (1995) Fault tolerant design using single and multi criteria genetic algorithms. Master’s thesis, Boston, MA: Department of Aeronautics and Astronautics Massachusetts Institute of technology.

Chen CT (2000) Extensions of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Set Syst 114:1–9

Chen G (2007) Multi-objective evaluation of dynamic facility layout using ant colony optimization. Dissertation, University of Texas.

Author information

Authors and Affiliations

Corresponding author

Appendix A

Appendix A

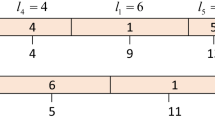

A dynamic facility layout consists of six departments and three time periods is considered. The same departments are to be arranged or rearranged across three time periods. The re-arrangement cost is 10. The material flow cost matrices (from–to charts), distance matrix, and closeness rating matrices are shown as below (Tables 11, 12, and 13):

-

Step 1 of methodology:

Table 14 shows the nondominated solutions obtained from the different methods employed (Table 15).

Table 14 Non-dominated solutions for each method used -

Step 2 of methodology:

For choosing the best solution, the set of nondominated solutions related to the NSGA-II algorithm (Table 14) is considered. By applying the TOPSIS method and based on the explained assumptions in Section 4, the nondominated solution 6 from NSGA-II column is selected as the best solution.

The solutions obtained using both proposed and Chen and Rogers’s methodology are shown in Table 16. As it can be seen, the solution of the proposed methodology dominates the solution of Chen and Rogers’ method.

Table 16 The solutions provided by proposed methodology and Chen and Rogers’s methodology

Rights and permissions

About this article

Cite this article

Emami, S., S. Nookabadi, A. Managing a new multi-objective model for the dynamic facility layout problem. Int J Adv Manuf Technol 68, 2215–2228 (2013). https://doi.org/10.1007/s00170-013-4820-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-013-4820-5