Abstract

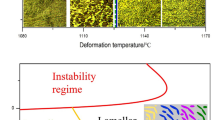

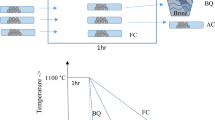

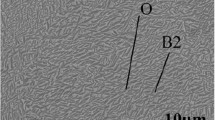

Power dissipation maps have been generated in the temperature range of 900 ‡C to 1150 ‡C and strain rate range of 10-3 to 10 s-1 for a cast aluminide alloy Ti-24Al-20Nb using dynamic material model. The results define two distinct regimes of temperature and strain rate in which efficiency of power dissipation is maximum. The first region, centered around 975 ‡C/0.1 s-1, is shown to correspond to dynamic recrystallization of the α2 phase and the second, centered around 1150 ‡C/0.001 s-1, corresponds to dynamic recovery and superplastic deformation of the β phase. Thermal activation analysis using the power law creep equation yielded apparent activation energies of 854 and 627 kJ/mol for the first and second regimes, respectively. Reanalyzing the data by alternate methods yielded activation energies in the range of 170 to 220 kJ/mol and 220 to 270 kJ/mol for the first and second regimes, respectively. Cross slip was shown to constitute the activation barrier in both cases. Two distinct regimes of processing instability—one at high strain rates and the other at the low strain rates in the lower temperature regions—have been identified, within which shear bands are formed.

Similar content being viewed by others

References

K. Muraleedharan: Ph.D. Thesis, Banaras Hindu University, Varanasi, India, 1995.

K. Muraleedharan, A.K. Gogia, T.K. Nandy, D. Banerjee, and S. Lele:Metall. Trans. A, 1992, vol. 23A, pp. 401–15.

S. Krishnan, T.K. Nandy, and D. Banerjee: Defence Metallurgical Research Laboratory, Hyderabad, India, [unpublished research,] 1994.

S.L. Semiatin, K.A. Lark, D.R. Barker, V. Seetharaman, and B. Marquardt:Metall. Trans. A, 1992, vol. 23A, pp. 295–305.

M. Long and H.J. Rack:Mater. Sci. Eng., 1993, vol. A170, pp. 215–26.

Y.V.R.K. Prasad, H.L. Gegel, S.M. Doraivelu, J.C. Malas, J.T. Morgan, K.A. Lark, and D.R. Baker:Metall. Trans. A, 1984, vol. 15A, pp. 1883–92.

P.K. Sagar, D. Banerjee, and Y.V.R.K. Prasad:Mater. Sci. Eng. A, 1994, vol. 117, pp. 185–97.

T.K. Nandy, R.S. Mishra, and D. Banerjee:Scripta Metall. Mater., 1993, vol. 28, pp. 569–74.

D. Banerjee, R.G. Rowe, and E.L. Hall:High Temperature Ordered Intermetallic Alloys—IV, Materials Research Society Symposia Proceedings, L.A. Johnson, D.P. Pope, and J.O. Stiegler, eds., 1991, vol. 213, pp. 285–90.

H.L. Gegel, J.C. Malas, S.M. Doraivelu, and V.A. Shende: Materials Research Society, Pittsburgh, PA,Metals Handbook, 1987, vol. 14, pp. 417–38.

Y.V.R.K. Prasad:Ind. J. Technol., 1990, vol. 28, pp. 435–51.

A.K. Kalyan Kumar: Master's Thesis, Indian Institute of Science, Bangalore, India, 1987.

C. Huang, T.A. Dean, and M.H. Loretto:Mater. Sci. Eng., 1995, vol. A191, pp. 39–47.

G. Schock: inDislocation in Solids, North Holland Publishing Company, Amsterdam, F. Nabarro, ed., 1980, vol. 3, pp. 63–163.

U.F. Kocks, A.S. Argon, and M.F. Ashby:Progress of Material Science, Pergamon Press, New York, NY, 1975, pp. 110–70.

W. Cho, A.W. Thomson, and J.C. Williams:Metall. Trans., 1990, vol. 21A, pp. 641–51.

M.G. Mendiratta and H.A. Lipsitt:J. Mater. Sci., 1980, vol. 15, pp. 2985–90.

R.S. Mishra and D. Banerjee:Mater. Sci. Eng., 1990, vol. 130, pp. 151–64.

P. Griffiths and C. Hammond:Titanium Science and Technology, Proc. Symp., R.I. Jaffee, and H.M. Burte, eds., TMS-AIME, Warrendale, PA, 1972, pp. 1155–67.

P.K. Sagar, D. Banerjee, and Y.V.R.K. Prasad: Defence Metallurgical Research Laboratory, Hyderabad, India, 1995, [unpublished work.]

S.A. Court, J.P.A. Lofvander, M.H. Loretto, and H.L. Fraser:Phil. Mag. A, 1990, vol. 61, pp. 109–39.

D. Banerjee:Phil. Mag. A, 1995, vol. 72(6), pp. 1559–87.

S.L. Semiatin and G.D. Lahoti:Metall. Trans. A, 1981, vol. 12A, pp. 1705–18.

S.L. Semiatin and G.D. Lahoti:Metall. Trans. A, 1981, vol. 12A, pp. 1719–28.

S.L. Semiatin and G.D. Lahoti:Metall. Trans. A, 1982, vol. 13A, pp. 275–88.

Author information

Authors and Affiliations

Additional information

Formerly with the Defence Metallurgical Research Laboratory

Rights and permissions

About this article

Cite this article

Sagar, P.K., Banerjee, D., Muraleedharan, K. et al. High-temperature deformation processing of Ti-24Al-20Nb. Metall Mater Trans A 27, 2593–2604 (1996). https://doi.org/10.1007/BF02652353

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02652353