Abstract

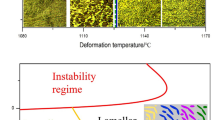

One of the attractive properties of Ti-6Al-4V alloy is control of microstructure through heat treatment to vary the mechanical properties. In this study, three different microstructures, Lamellar, Widmanstätten, and Martensitic morphologies, were created through heat treatment at a post-β transus temperature followed by cooling at different rates. With faster cooling rates, the microstructures evolved finer lamellae, smaller colony sizes, and thinner grain boundary layers. High-temperature dynamic compression was conducted on these specimens at a strain rate of 1000 s−1 and temperatures in the range of 23 °C to 1045 °C. Flow stresses decreased linearly with colony size and grain boundary layer thickness, but increased with inverse square root of lamellar thickness. This strong correlation of flow stress to several microstructural feature sizes indicated multiple modes of deformation. All three microstructures showed identical thermal softening. The softening rate was intensified at elevated temperatures due to hcp → bcc allotropic phase transformation. Gangireddy modification to Johnson–Cook model could account for this augmented softening and the modified J–C model predicted the three microstructures to follow a similar thermal softening coefficient m = 0.8. The kinetics of phase transformation appear to be very rapid irrespective of the microstructural differences in the Ti-6Al-4V alloy.

Similar content being viewed by others

References

R. Reda, A.A. Nofal, A.H.A. Hussein, J. Metall. Eng. ME., 2013, vol 2, pp. 48-55.

T. Mohandas, D. Banerjee, V.V.K. Rao, Mater. Sci. Eng. A, 1998, vol. 254, pp. 147–154,

R. Filip, K. Kubiak, W. Ziaja, and J. Sieniawski, J. Mater. Process. Technol., 2003, vol. 133, pp. 84–89.

A. Attanasio, M. Gelfi, A.Pola, E. Ceretti, C. Giardini, Materials, 2013, vol. 6, pp. 4268-4283.

S. Cedergren, G. Sjöberg, G. Petti, Procedia CIRP, 2013, vol. 12, pp. 55-60.

S.J. Sun, M.Brandt, J.Mo, Adv. Mater. Res., 2013, vol.690-693, pp. 2437-2441.

M. Nouari, H. Makich, Metals, 2014, vol. 4, pp. 335-358.

K.A. Hartley, J. Duffy, R.H. Hawley, J. Mech. Phys. Solids, 1987 vol. 35, pp. 283-301

D.K. Kim, S.Y. Kang, S. Lee, K.J. Lee, Metall. Mater. Trans A, 1999, vol. 30A, pp. 81-92.

H.J. Ryu, S.H. Hong, D. K. Kim, S. Lee, Metals and Materials., 1998, vol. 4, pp. 367-371.

A. Marchand, J. Mech. Phys. Solids., 1988, vol. 35, pp. 252-261.

D.G. Lee, S. Lee, C.S. Lee, S. Hur, Metall. Mater. Trans. A, 2003, vol. 34A, pp. 2541-2548.

D.G. Lee, S. Kim. S. Lee, C.S. Lee, Metall. Mater. Trans. A, 2001, vol. 32A, pp. 315-324.

D.G. Lee, S. Lee, C.S. Lee, Mater. Sci. Eng. A, 2004, vol. 366, pp. 25-37

A.W. Johnson, C.W. Bull, K.S. Kumar, C.L. Briant, Metall. Mater. Trans. A, 2003, vol. 34A, pp. 295- 306

S.P. Mates, R. Rhorer, E. Whitenton, T. Burns, D. Basak. Exp. Mech., 2008, vol. 48, pp. 799-807.

M. Donachie: Titanium: A Technical Guide, 2nd ed., ASM International, 2000, Chap. 3, pp. 13–25.

S. Gangireddy, S.P. Mates, J. Dyn. Behav. Mat., 2017, vol. 3, pp. 557-574.

D. Basak, H. W. Yoon, R. Rhorer, T. Burns, AIP Conf. Proc. 2003, vol. 684, pp. 753-759.

D. Basak, R.A. Overfelt, D. Wang, Int. J. Thermophys., 2004, vol. 252, pp. 561-574.

E.S.K. Menon, H.I. Aaronson, Metall. Mater. Trans. A, 1986, vol. 17A,pp. 1703-1715

T. Ahmed, H.J. Rack, Mater. Sci. Eng. A, 1998, vol. 243,pp. 206-211

G. Lutjering, Mater. Sci. Eng. A, 1998, vol. 243, pp. 32-45

F.S. Lin, E.A. Starke, S.B. Chakrabortty, A. Gylser, Metall. Mater. Trans. A, 1984, vol. 15, pp. 1229-1246

F.J. Gil, M.P. Ginebra, J.M. Manero, J. Alloys Compd., 2001, vol. 329, pp. 142-152.

R.S. Sandala: Ph.D. Thesis, Deformation Mechanisms of Two-Phase Titanium Alloys, University of Manchester UK (2013), pp. 95–105

A.A. Antonysamy: Ph.D. Thesis, Microstructure, Texture and Mechanical Property Evolution during Additive Manufacturing of Ti6Al4V Alloy for Aerospace Applications, University of Manchester UK, 2012, pp. 290–94.

M.A. Meyers, G. Subhash, B.K. Krad, L. Prasad, Mech. Mater., 1994, vol. 17, pp. 175-193.

Q. Li, Y.B. Xu, M.N. Bassim, J. Mater. Process. Technol., 2004, vol. 155, pp. 1889-1892.

K.S. Chan, C.C. Wojcik, D.A. Koss, Metall. Mater. Trans. A, 1981, vol. 12A, pp.1899-1907.

J.M. Manero, F.J. Gil, J.A. Planell, Mater., 2000, vol. 48, pp. 3353-3359.

T. Seshacharyulu, S. C. Medeiros, W. G. Frazier, and Y. V. R. K. Prasad, Mater. Sci. Eng. A, 2002, vol. 325, pp. 112–125.

Acknowledgments

The author gratefully acknowledges the support of Dr. Steven Mates and NIST Mechanical Performance Group as well as James Warren, NIST Technical Program Director for Materials Genomics. I also acknowledge the valuable assistance of Mr. Eran Vax and Mr. Eli Marcus of the Nuclear Research Center, Negev, Israel, for many improvements to the electrical heating control system.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted February 27, 2018.

Rights and permissions

About this article

Cite this article

Gangireddy, S. Effect of Initial Microstructure on High-Temperature Dynamic Deformation of Ti-6Al-4V Alloy. Metall Mater Trans A 49, 4581–4594 (2018). https://doi.org/10.1007/s11661-018-4774-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-018-4774-1