Abstract

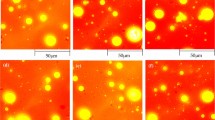

Polymer-modified bitumen (PMB) has been increasingly used to enhance pavement performance. Two styrenebutadiene-styrene (SBS) copolymers were mixed with two bitumens by weight of the blend. This paper aims at developing the procedure to determine the proper polymer content to be mixed with bitumen. Tests including storage stability test, dynamic shear rheometer and scanning electron microscopy (SEM) were conducted to investigate the viscoelastic properties and microstructures of PMB. The addition of polymers increased the viscosity, softening point, toughness and complex modulus of bitumens. SEM results indicated that, as the polymer content increased, SBS gradually became the dominant phase that resulted in an increase in PMB's mechanic properties. Good compatibility produced an elastic network into the PMB up to 6% polymer concentration. The optimum polymer content was determined based on the rheological properties and the formation of the critical network. Adding higher polymer contents could lead to the separation of polymer and bitumen. The softening point temperature difference between top and bottom samples should be controlled within 2°C to monitor PMB's stability.

Résumé

Le bitume modifié par polymère (PMB) est de plus en plus utilisé pour renforcer la durabilité du pavé. Deux copolymères styrène-butadiène-styrène (SBS) sont mélangés à deux bitumes par poids de mélange. La recherche proposée dans cet article a pour objectif le développement d'une procédure permettant de déterminer la quantité exacte de polymères à mélanger aux bitumes. Des tests de stabilité de stockage, de dynamique de contrainte au rhéomètre, et de microscope électronique à balayage (MEB) ont permis d'étudier les propriétés visqueuses et élastiques du PMB et ses structures microscopiques. L'addition de polymères augmente le coefficient de viscosité, le point d'amollissement, la résistance, et le complexe modulaire des bitumes. Les résultats du MEB montrent que quand la quantité de polymères croît, le SBS devient la phase principale qui résulte en un renforcement des propriétés mécaniques du PMB. Une bonne compatibilité entre les polymères et les bitumes engendre un réseau élastique dans le PMB, jusqu'à une concentration de 6% de polymères. La quantité optimale de polymères est déterminée sur la base des propriétés rhéologiques et la formation du réseau critique. Une addition de polymères produirait une séparation des polymères et des bitumes. La différence des températures d'amollissement entre les échantillons supérieurs et inférieurs doit être maintenue à deux degrés Celsius pour pouvoir surveiller la stabilité du PMB.

Similar content being viewed by others

References

Drescher, A., Kim, J.R. and Newcomb, D.E., ‘Permanent deformation in asphalt concrete’,Journal of Materials in Civil Engineering 5 (1993) 112–128.

Collop, A.C., Cebon, D. and Hardy, M.S.A., ‘Viscoelastic approach to rutting in flexible pavements’,Journal of Transportation Engineering 121 (1995) 82–93.

Choquet, F.S. and Ista, E.J., ‘The determination of SBS, EVA and APP polymers in modified bitumens’,Polymer Modified Asphalt Binders, ASTM Special Technical Publication 1108 (1992) 35–49.

King, G.N., King, H.W., Harders, O., Arand, W., Chaverot, P. and Planche, J.P., ‘Influence of asphalt grade and polymer concentration on the high temperature performance of polymer modified asphalt’,Journal of Association of Asphalt Paving Technologists 61 (1992) 29–61.

Blanco, R., Rodriguez, R., Garcia-Garduno, M. and Castano, V.M., ‘Morphology and tensile properties of styrene-butadiene copolymer reinforced asphalt’,Journal of Applied Polymer Science 56 (1995) 57–64.

Bonemazzi, F., Braga, V., Corrieri, R., Giavarini, C. and Sartori, F., ‘Characteristics of polymers and polymer-modified binders’,Transportation Research Record 1535 (1996) 36–47.

Giavarini, C., Filippis, P.D., Santarelli, M.L. and Scarsella, M., ‘Production of stable polypropylene-modified bitumens’,Fuel 75 (1996) 681–686.

Gahvari, F., ‘Effects of thermoplastic block copolymers on rheology of asphalt’,Journal of Materials in Civil Engineering 9 (1997) 110–116.

Lu, X., Isacsson, U. and Ekblad, J., ‘Rheological properties of SEBS, EVA and EBA polymer modified bitumens’,Mater. Struct. 32 (1999) 131–139.

Shin, E.E., Bhurke, A., Scott, E., Rozeveld, S. and Drzal, L.T., ‘Microstructure, morphology, and failure modes of polymer-modified asphalt’,Transportation Research Record 1535 (1996) 61–73.

Williams, T.M. and Miknis, F.P., ‘Use of SEM to study asphalt-water interactions’,Journal of Materials in Civil Engineering 10 (1998) 121–125.

Schalek, R.L. and Drzal, L.T., ‘Characterization of advanced materials using SEM’,Journal of Advanced Materials 2 (2000) 32–38.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Chen, J.S., Liao, M.C. & Lin, C.H. Determination of polymer content in modified bitumen. Mat. Struct. 36, 594–598 (2003). https://doi.org/10.1007/BF02483278

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF02483278