Abstract

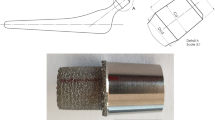

To reduce production costs of forged parts, different approaches are possible. Especially for valuable materials like titanium, material costs represent a large part of the production costs. Therefore, reducing the initial material can decrease the total costs significantly. In order to identify the potential for improvements, an existing forging sequence was investigated. For a titanium hip implant, a forging sequence was developed. To reduce the initially needed material, cross wedge rolling as a preforming operation and die forging with flash brakes was investigated. The influence of the different stages on the final result was analysed and presented in detail. To increase the prediction accuracy of the newly developed flash-reduced forging sequence and decrease iteration loops of die designs, feasible simulation parameters considering the boundary conditions of the forging environment were investigated. This is done using Finite Element Analysis (FEA), considering form filling, process stability, die stress and press forces. Using cross wedge rolling and die forging with flash brakes, the newly developed forging sequence reduces the flash rate significantly from 69% to 32%.

Similar content being viewed by others

References

EuroFORGE (2014) 2014 world-wide survey., Accessed 16 November 2015

Ritter C (2009) Impulsprogramm Materialeffizienz macht Unternehmen fit für den Wettbewerb. Intelligenter Produzieren 4:40

Lütjering G, Williams JC (2007) Titanium. 2nd Edition, Springer Verlag, Berlin

Seliger G et al. (2013) Studie: Analyse von Potenzialen der Material- und Energieeffizienz in ausgewählten Branchen der Metall verarbeitenden Industrie; VDI Zentrum Ressourceneffizienz GmbH, Berlin

Lange K (1988) Umformtechnik Band 2: Massivumformung. Springer-Verlag, Berlin u. a

Li Q, Lovell M (2008) Cross wedge rolling failure mechanisms and industrial application. Int J Adv Manuf Technol. doi:10.1007/s00170-007-0979-y

Herbertz R, Hermanns C (1997) Querkeilwalzen. Ein wirtschaftliches und flexibles Vorformverfahren für die Großserienfertigung. Schmiede J Industrieverband Massivumformung 2:20–21

Blohm T, Stonis M, Behrens BA (2015) Investigation of simulation parameters for cross wedge rolling titanium and Bainitic grade steel. Appl Mech Materials, Trans Tech Publ, Switzerland 736:165–170

Kache H, Stonis M, Behrens BA (2012) Development of a warm cross wedge rolling process using FEA and downsized experimental trials. Prod Eng Res Devel doi. doi:10.1007/s11740-012-0379-5

Behrens BA, Bouguecha A, Suchmann P, Schott A (2008) Warm forging: new forming sequence for the manufacturing of long flat pieces. In: Production Engineering, Springer Verlag Berlin, 2, 3, pp. 261–268.

Li Q et al (2002) Investigation of the morphology of internal defects in cross wedge rolling. J Mater Process Technol. doi:10.1016/S0924-0136(02)00303-5

Cakircali M et al (2013) Cross wedge rolling of a Ti6Al4V (ELI) alloy: the experimental studies and the finite element simulation of the deformation and failure. Int J Adv Manuf Technol. doi:10.1007/s00170-012-4256-3

Behrens BA et al (2013) Basic study on the process combination of deposition welding and subsequent hot bulk forming. Prod. Eng. Res. Devel. doi. doi:10.1007/s11740-013-0478-y

Tofil A, Tomczak J, Pater Z (2013) Cross wedge rolling with upsetting. Arch Metall Mater. doi:10.2478/amm-2013-0150

Bartnicki J, Pater Z, Gontarz A, Tomczak J (2014) Innovative metal forming technologies. J Mach Eng 14:5–16

Meyer M, Stonis M, Behrens BA (2015) Cross wedge rolling and bi-directional forging of preforms for crankshafts. Production engineering, Research and Development. Springer Verlag Berlin 9:61–71

Li L; Wang F (2014) Use of fractional design for flash gap with wall lands in closed die forging, materials research innovation, Springer Verlag Berlin 18(1): 81–83

Langner J, Stonis M, Behrens BA (2015) Experimental investigation of a variable flash gap regarding material flow and influence of trigger forces, production engineering, Research and Development, Springer Verlag 9(3): 289–297

Langner J, Stonis M, Behrens BA (2016) Investigation of a moveable flash gap in hot forging. J Mater Process Technol Elsevier BV Amsterdam 231:199–208

Altan T, Vazquez V (1996) Numerical process simulation for tool and process design in bulk metal forming, CIRP Annals - Manufacturing Technology, Elsevier Ltd, 45(2): 599–615

Behrens BA, Bouguecha A, Hadifi T, Mielke J (2015) Advanced friction modeling for bulk metal forming processes, production engineering, Research and Development, Springer Verlag Berlin, 5(6):621–627

Acknowledgment

The research leading to these results has received funding from the European Union’s Seventh Framework Programme managed by REA-Research Executive Agency http://ec-europe.eu/rea (FP7/2007-2013) under grant agreement n° 606171 FP7-SME-2013-1.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This study was funded by the European Union’s Seventh Framework Programme managed by REA-Research Executive Agency http://ec-europe.eu/rea (FP7/2007–2013) (grant number 606,171 FP7-SME-2013-1).

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Behrens, BA., Stonis, M., Blohm, T. et al. Investigating the effects of cross wedge rolling preforming operation and die forging with flash brakes on forging titanium hip implants. Int J Mater Form 11, 67–76 (2018). https://doi.org/10.1007/s12289-016-1329-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-016-1329-0