Abstract

The antioxidant capacity (AC) of rapeseed, white flakes, and meal was determined by the novel cerium oxide nanoparticle-based (CeONP) method and a previously described assay based on the formation of silver nanoparticles (AgNP). Antioxidants present in rapeseed and its by-product extracts reduced cerium(IV) ions to red-purple solutions of cerium oxide nanoparticles at pH 5.6. The influences of time, temperature, pH, and the concentration of the cerium(IV) sulfate solution on cerium oxide nanoparticle generation were estimated. The average AC of the studied extracts of real samples ranged between 1037 and 3012 μmol sinapic acid (SA) 100 g−1 and 3859–12,534 μmol SA 100 g−1 for CeONP and AgNP assays, respectively. There is significant, positive correlation between the AC of the examined extracts determined by both analytical methods (r = 0.8189). Satisfactory values of relative standard deviation (RSD = 1.2–3.9 %) and recovery (95.8–103.3 %) demonstrate a good precision and accuracy of the novel CeONP method for the AC analysis of rapeseed and its by-products.

Reaction mechanism of cerium ions reduction by sinapic acid was proposed for a new cerium oxide nanoparticle-based (CeONP) method

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nanomaterials have specific biological, thermal, mechanical, optical, electrical, and magnetic properties and can be adapted to the desirable effect by changing their size, shape, and the extent of agglomeration. It has been known that metal and metal oxide nanoparticles, quantum dots, nanowires, nanorods, and carbon nanotubes can be used in analytical chemistry for the preparation of samples, separation, and detection (Vilela et al. 2015b). Currently, nanomaterials are increasingly applied for analysis of the antioxidant potential of various food products (Özyürek et al. 2012; Pelle et al. 2015a, b; Vilela et al. 2015b).

The antioxidants present in food play a very important role in the human body because they are capable of slowing or preventing the oxidation processes. These compounds are involved in the prevention and treatment of cancer, stroke, autism, Alzheimer’s dementia, arthritis, aging, cardiovascular disease, Parkinson’s disease, and others. Therefore, consumption of natural antioxidants in the daily diet or use of isolated compounds in clinical practices would be beneficial for health. Also, some constituents of oilseeds and vegetable oils such as tocopherols, carotenoids, phytosterols, phytostanols, polyphenols, vitamins, and phospholipids exhibit antioxidant activity (Naczk et al. 1998; Papadopoulos et al. 2003; Pelle et al. 2015a, b; Szydłowska-Czerniak et al. 2012, 2015; Szydłowska-Czerniak and Tułodziecka 2013; Tura et al. 2007). Among them, rapeseed cultivars containing high amounts of antioxidants are one of the most common sources of the healthiest vegetable oil for human consumption in Europe (Kimber and McGregor 1995; Naczk et al. 1998; Nesi et al. 2008). Moreover, during the production of rapeseed oil, by-products such as rapeseed meal and white flakes are formed. Rapeseed meal derived from the rapeseed oil extraction process is rich in protein, with a well-balanced amino acid composition; thus, it can be utilized in animal feed and as an organic fertilizer (Khattab and Arntfield 2009; Yoshie-Stark et al. 2008). However, bioactive compounds such as phenolic compounds, tocopherols, vitamin B, and choline and bioelements like calcium, magnesium, zinc, and copper present in meal can be exploited as functional additives (Vuorela et al. 2004). On the other hand, white flakes are an intermediate material for the production of protein concentrates. They contain undenatured proteins, which can be used for the production of the extruded feed possessing high protein dispersibility index and antioxidant level (Maenz 2007). Therefore, bioactive compounds present in rapeseed and its by-products have important biological and chemical properties, which include antioxidant capacity (AC), ability to scavenge active oxygen species and electrophiles, inhibition of nitrosation reactions, and chelating pro-oxidant metals (Shahidi and Ho 2005).

In recent years, different analytical nanoparticle-based methods have been proposed for the assessment of the total AC of foods and plants. The AC of polyphenol standards, fruit juices, herbal teas, rapeseed varieties, and its products was analyzed by the silver nanoparticle-based (AgNP) method (Özyürek et al. 2012; Szydłowska-Czerniak et al. 2012; Szydłowska-Czerniak and Tułodziecka 2013). However, a gold nanoparticle-based (AuNP) assay was developed for evaluating the AC of chrysanthemum extracts, various teas, beverages, juice samples, extracts of different parts of plants, fruits of amla and Indian gooseberry, virgin and adulterated argan oils, honey, fresh apples and pears, wines, soybean, and extra virgin olive oils (Choleva et al. 2015; Liu et al. 2012; Pelle et al. 2015a, b; Roy et al. 2011; Scampicchio et al. 2006; Vilela et al. 2012, 2014, 2015a, b; Zougagh et al. 2011). Furthermore, the effect of refining processes on the AC of rapeseed oil was evaluated by the iron oxide nanoparticle-based method (Szydłowska-Czerniak et al. 2015). Also, ceria nanoparticles were utilized to assess the AC of teas and medicinal mushroom samples (Sharpe et al. 2013). In addition, a spectrophotometric method based on the oxidation of the antioxidants present in herbal samples by cerium(IV) sulfate in dilute sulfuric acid at room temperature was reported (Ozyurt et al. 2007, 2010). These same authors applied a spectrofluorometric method based on the reduction of Ce4+ by antioxidants to Ce3+ ions, which exhibited strong fluorescence at 360 nm with an excitation wavelength of 256 nm for the AC determination of different teas: green tea bags (Camellia sinensis), nettle herbal tea bags (Urtica dioica/urens), linden tea bags (Tilia), mint tea bags (Mentha spicata), sage herbal tea bags (Salvia officinalis), and chamomile (Matricaria chamomilla L.; Ozyurt et al. 2011).

Nevertheless, there has been no reference on the AC analysis of rapeseed, white flakes, and meal by the cerium oxide nanoparticle-based (CeONP) assay. Therefore, in the present paper, the CeONP method for the AC determination of rapeseed and its by-products was described. The proposed new CeONP method is based on the optical properties of cerium oxide nanoparticles which reveal characteristic absorption bands in the UV–Vis region. The validation of the proposed CeONP method was statistically performed on sinapic acid, the predominant phenolic acid in rapeseed. Moreover, the effects of time, temperature, pH, and the concentration of the cerium(IV) sulfate solution on the cerium reduction assay by a methanolic solution of sinapic acid were evaluated. The AC results of rapeseed, white flakes, and meal obtained by the novel CeONP method and the previously described AgNP assay were compared and discussed.

Materials and Methods

Chemicals

All reagents were of analytical or HPLC grade. Sinapic acid (SA, 98 %), cerium(IV) sulfate tetrahydrate (Ce(SO4)2⋅4H2O, 98 %), and silver nitrate (AgNO3, 99 %) were purchased from Sigma-Aldrich (Poznań, Poland). Acetic acid (99 %), ammonia (25 %), ammonium nitrate, methanol (99.8 %), and sodium acetate were obtained from POCH (Gliwice, Poland). Redistilled water was used for the preparation of solutions.

The 8.0-mmol L−1 cerium(IV) sulfate solution was prepared daily in redistilled water and mixed at room temperature for 2 h, obtaining a slightly green-yellow and clear solution. Acetic buffer at pH 5.6 was prepared by adding 4.8 mL of acetic acid solution (0.2 mol L−1) and 45.2 mL of sodium acetate solution (0.2 mol L−1) and diluting redistilled water to 100 mL. Ammonium buffer at pH 8.4 was prepared by dissolving 11.2 g of ammonium nitrate in redistilled water, adding 1.5 mL of ammonia solution (25 %), and diluting to 200 mL. The pH of these buffer solutions was adjusted and checked with a pH meter.

Instruments

The UV–Vis spectra were measured using a Hitachi U-2900 (Tokyo, Japan) spectrophotometer in a 1-cm quartz cell. The pH measurements were made with a pH meter (Mettler Toledo, SevenGo™, Warsaw, Poland). The shaker SK-L330-Pro (Medlab, Raszyn, Poland), centrifuge MPW-54 (MPW Med. Instruments, Warsaw, Poland), heating plate (Chemland, Stargard Szczeciński, Poland), technical balance WTB 2000 (Radwag, Radom, Poland), analytical balance (OHAUS, Warsaw, Poland), and incubator INP 500 (Memmert, Schwabach, Germany) were used for sample preparation. The cerium oxide deposition process was studied using a scanning electron microscope (SEM; LEO 1460V, Cambridge, UK) and an atomic force microscopy instrument (Veeco, Multimode, Nanoscope IIIa Controller, Tapping Mode AFM, Santa Barbara, CA, USA).

Samples

A winter open-pollinated rapeseed variety of Brassica napus L. (double low, without erucic acid and glucosinolates), rapeseed white flakes, and rapeseed meal were provided by a local vegetable oil factory. White flakes were obtained from the dehulled flaked rapeseed by extracting oil with hexane and flash-desolventizing the defatted rapeseed flakes to minimize protein denaturation. Rapeseed meal was obtained from the dehulled flaked rapeseed by extracting oil with hexane and then desolventizing the defatted flakes by means of high-temperature thermal processing. All samples in the original poly(ethylene terephthalate) packaging were stored at ambient temperature until treatment and further analysis.

Sample Preparation for the Determination of Antioxidant Capacity

In this study, methanol, methanol–water (1:1, v/v), and water were used for the extraction of antioxidants from the studied samples. A 2.0-g portion of ground rapeseed, white flakes, and meal and 20 mL of each solvent with decreasing polarity (dielectric constant = 78.4 (water), 56.3 (50 % methanol), and 32.6 (methanol)) were transferred into round-bottomed flasks and shaken at room temperature for 20 min. Each sample was extracted in triplicate and the residual flour was separated by centrifugation (4500 rpm, 15 min). The pooled extracts were filtered and stored in a refrigerator prior to analysis.

Antioxidant Capacity Determination

Cerium Oxide Nanoparticle-Based Method

Exactly 1.0 mL of 8.0 mmol L−1 cerium(IV) sulfate, 1.0 mL of acetic buffer (pH 5.6), and 0.5 mL of methanolic, 50 % methanolic, or aqueous extract of each sample were placed into a 10-mL volumetric flask and made up to volume with redistilled water. After 30 min, the absorbance of a clear red-purple solution was measured at 510 nm against a reagent blank (1.0 mL of 8.0 mmol L−1 cerium(IV) sulfate and 1.0 mL of acetic buffer and made up to 10 mL with redistilled water).

The influence of time and temperature on Ce4+ reduction by a methanolic solution of sinapic acid was estimated. For this purpose, 1.0 mL of 8.0 mmol L−1 cerium(IV) sulfate, 1.0 mL of acetic buffer (pH 5.6), and 1.5 mL of 0.6 μmol SA mL−1 were placed into a 10-mL volumetric flask, made up to volume with redistilled water, incubated at 20, 40, 60, 80, and 100 °C for 30 min, and the absorbance measured at 510 nm against a reagent blank. The change of color intensity at λ = 510 nm in time varying from 0 to 120 min was evaluated. Also, the effect of pH on cerium oxide nanoparticle synthesis was determined by adjusting the pH of the reaction mixtures (1 mL of 8.0 mmol L−1 cerium(IV) sulfate and 1 mL of 0.6 μmol mL−1 sinapic acid) to 3.6, 4.6, 5.6, 7.0, 7.6, 8.6, and 9.6 using acetic and ammonium buffers. Moreover, the impact of different concentrations of cerium(IV) sulfate solutions on the formation of cerium oxide nanoparticles was studied as follows: 1.0 mL of acetic buffer (pH 5.6), 2.0 mL of 0.6 μmol mL−1 sinapic acid, and 0.25, 0.50, 1.00, 1.50, and 2.00 mL of 8.0 mmol L−1 Ce(SO4)2 were placed into 10-mL volumetric flasks, respectively, and made up to the mark with redistilled water.

Silver Nanoparticle-Based Method

The AC of the studied rapeseed, white flakes, and meal was determined by the AgNP spectrophotometric method, as described in our previous study (Szydłowska-Czerniak et al. 2012). Briefly, 0.2 mL of methanolic, 50 % methanolic, or aqueous extract of each sample, 1.0 mL of ammonium buffer (pH 8.4), and 1.0 mL of 10 mmol L−1 silver nitrate were placed into a 10-mL volumetric flask and made up to volume with redistilled water. After 60 min, the absorbance of a yellow-orange solution was measured at 405 nm against a reagent blank (1.0 mL of ammonium buffer and 1.0 mL of 10 mmol L−1 silver nitrate made up to 10 mL with redistilled water).

Calibration curves were prepared using working solutions of sinapic acid in methanol between 0.03 and 0.21 μmol mL−1. The least-squares method was applied to calculate the line equation: A 405 [a.u.] = (4.34 ± 0.14) × c SA [μmol mL−1] − (0.021 ± 0.019), resulting in a linear correlation coefficient (r = 0.9974), RSDslope = 1.57 % (n = 5), and molar extinction coefficient (ε = 4.1 × 103 L mol−1 cm−1) for sinapic acid.

Scanning Electron Microscopy and Atomic Force Microscopy Analyses

The 1.0 mL of 8.0 mmol L−1 cerium(IV) sulfate, 1.0 mL of acetate buffer (pH 5.6), and 0.5 mL of rapeseed meal extract prepared in 50 % methanol were transferred into a 10-mL volumetric flask and made up to volume with redistilled water. The mixture was kept in the dark for 30 min at ambient temperature. The silicon wafer was immersed in the prepared solution containing cerium oxide nanoparticles and immediately placed in a furnace at 180 °C for 16 h. The morphology of the obtained cerium oxide nanoparticles was visualized by scanning electron microscopy (SEM) and atomic force microscopy (AFM).

Statistical Analysis

The AC results determined by the proposed CeONP and AgNP methods were presented as mean values (n = 5) ± standard deviation (SD). Differences between AC means were detected using Duncan test (p < 0.05). The within-day precision of the analytical methods was expressed as the relative standard deviation (RSD, in percent). Moreover, Pearson correlation test was used to assess the relationship between the AC of the studied extracts of rapeseed, white flakes, and meal analyzed by both analytical methods. Furthermore, the accuracy of the novel method (CeONP) was determined using a recovery test. For this purpose, a fixed amount of sinapic acid standard solution (0.03 μmol mL−1) was added to extracts of the analyzed samples and the percent recovery was calculated as follows: [AC of spiked extract/(AC of extract + 0.03 μmol mL−1 of sinapic acid solution)] × 100 %.

Results and Discussion

Characteristics of the Novel CeONP Method

The following reaction mechanism of cerium ion reduction by sinapic acid was proposed for a new CeONP assay:

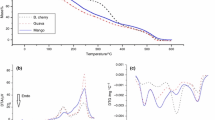

It can be noted that sinapic acid possesses a phenolic nucleus and an unsaturated side chain, which can be oxidized by cerium(IV) sulfate in acidic medium (pH 5.6). The hydroxyl group in the aromatic ring and the alkene bond of sinapic acid were oxidized easily and the corresponding quinone structure and oxalic acid were formed, respectively (Wang et al. 2008). At the same time, cerium ions were reduced to Ce x O y nanoparticles, resulting in the strong signal in visible range (Fig. 1).

The absorption peak at 510 nm was not observed in the UV–Vis spectra of 0.060 μmol mL−1 sinapic acid solution and 0.8 mmol L−1 cerium(IV) sulfate solution. The presence of a characteristic absorbance band at 510 nm indicates the generation of cerium oxide nanoparticles (Fig. 1).

Cerium oxide nanoparticles have the ability to undergo a facile conversion between Ce(IV) and Ce(III) oxidation states. Probably, the tetravalent Ce ions were reduced in a reducing medium (presence of antioxidants) to trivalent Ce ions and the red-purple color indicates the presence of Ce2O3 nanoparticles. It is evident that all Ce(III) ions were not oxidized during the reaction time and conditions. Some Ce ions remained as trivalent ions and were introduced into the cavity and formed the Ce2O3 nanoparticles (Okuda et al. 2011). The higher portion of Ce3+ having the deficiency of positive charge causes more intrinsic defects in the cerium oxide structure, which can be compensated by oxygen vacancies. This fact suggests that cerium oxide is an oxygen-deficient, non-stoichiometric oxide (CeO2–x , with 0 < x ≤ 0.5; Samiee and Goharshadi 2012). Moreover, an increase in the Ce+3 valance state with decreasing particle size was observed (Korsvik et al. 2007; Naganuma and Traversa 2012). Therefore, the size of cerium oxide nanoparticles depends on the ratio of Ce(III)/Ce(IV) and the intensive red-purple color confirms the generation of smaller non-stoichiometric cerium oxide nanoparticles (Ornatska et al. 2011). Although the presence of sulfate ions in a solution can accelerate the agglomeration of these nanoparticles (Masui et al. 2002).

As can be seen in Fig. 2, time, temperature, pH, and the concentration of the cerium(IV) sulfate solution affected the reducing properties of sinapic acid.

The color change can be observed in the methanolic solutions of sinapic acid (c = 0.090 μmol mL−1) after incubation with Ce(SO4)2 solution (c = 0.8 mmol L−1) in pH 5.6 at 0–120 min. It is noteworthy that cerium oxide nanoparticle formation significantly enhanced as the contact time was extended to 30 min, but after that, only a slight variation of the absorbance at 510 nm could be seen (Fig. 2a). Moreover, the incubation temperature of the reaction mixtures had an impact on the generation of cerium oxide nanoparticles. At lower temperatures (20, 40, and 60 °C), solutions of cerium oxide nanoparticles revealed red-purple and light red colors, whereas the light pink and orange colors were characteristic for solutions incubated at 80 and 100 °C (Fig. 2b). It can be noted that the rate of cerium oxide nanoparticle formation reduced with the increase of the reaction temperature to 40 °C (Fig. 2b). The slight increase in the absorbance at 510 nm was observed as the temperature increases to 60 °C. Further increase of temperature to 100 °C caused a decrease in the formation of cerium oxide nanoparticles (Fig. 2b). One possible explanation for this fact is a decrease in the antioxidant efficiency of sinapic acid, responsible for the reduction of Ce4+ ions, as well as the agglomeration of nanoparticles.

In addition, the absorbance at λ = 510 nm continuously increased along with the pH increase to 5.6, suggesting progressive generation of cerium oxide nanoparticles (Fig. 2c). However, a further pH increase up to 9.6 reduced the absorbance. This fact indicated that Ce(IV) oxyhydroxides at elevated pH were formed. Evidently, the pH value of the solution affects the Ce3+/Ce4+ conversion and cerium oxide nanoparticle morphology. At a low pH, the reaction mainly involves Ce(III) oxidation and Ce(IV) reduction, whereas at higher pH, only Ce(III) oxidation occurs; thus, a high pH value favors Ce(III) oxidation. This suggests that oxidation from Ce3+ to Ce4+ is easier in an alkaline solution. In addition, the decrease of the pH value causes the increase of Ce4+ solubility from the CeO2 nuclei, which can induce an increased dissolution/precipitation process and the formation of crystals with sharp corners and edges. The solubility of CeO2 decreases with the pH increase, and particles with more surface defects were generated. However, the hydrated cerium oxide nanoparticles possess both acidic and alkaline characteristics: due to the loss of protons, their surface demonstrates negative charges at alkaline conditions—hydrogen ions can be gained from oxygen anions as well—and reveals positive charges at acidic solution (Bumajdad et al. 2009; Lin et al. 2012; Yan et al. 2007).

Furthermore, the amount of cerium oxide nanoparticles would become negligible if the concentration of the Ce(SO4)2 solution was low. The increase of the Ce(SO4)2 concentration to 0.8 mmol L−1 increased the production of cerium oxide nanoparticles; therefore, the absorbance at 510 nm gradually enhanced. However, reduction of the absorbance due to the agglomeration of cerium oxide nanoparticles formed by more concentrated Ce(SO4)2 solutions, as well as the hydrolysis of Ce4+ ions proportional to their concentration, was observed (Fig. 2d).

Therefore, the proposed CeONP method can be effectively used for AC determination under the following conditions: the reaction mixture of 1.0 mL of 8.0 mmol L−1 cerium(IV) sulfate, 1.0 mL of acetic buffer (pH 5.6), and 0.5 mL of sample extracts should be made up to 10 mL with redistilled water and incubated at room temperature (20 °C) for 30 min.

The novel CeONP method was evaluated with respect to linearity, precision, accuracy, sensitivity, and limits of detection (DL) and quantification (QL). Five calibration curves for the new CeONP method were obtained by diluting the corresponding stock solution (0.6 μmol mL−1) of sinapic acid between 0.006 and 0.090 μmol mL−1 and plotted on the same day. The least-squares method was applied to calculate the line equation: A 510 [a.u.] = (10.42 ± 0.12) × c SA [μmol mL−1] + (0.048 ± 0.007), resulting in a linear correlation coefficient (r = 0.9996) and RSDslope = 2.8 % (n = 5). The AC results were expressed in micromoles SA equivalents per 100 g of sample. The within-day precision of the CeONP method was tested by analysis of a sample containing 0.060 μmol SA mL−1 in five replicates. The obtained value of RSD = 3.6 % indicates reasonable repeatability of the proposed new assay. Moreover, the calculated detection (DL = 2.75 × 10−3 μmol SA mL−1) and quantification (QL = 9.17 × 10−3 μmol SA mL−1) limits confirm the linearity of the concentration range for AC determination. The CeONP method appeared to be sensitive (ε = 1.24 × 104 L mol−1 cm−1 for sinapic acid).

The formation of cerium oxide nanoparticles in the studied system was confirmed by the AFM and SEM analyses and presented in Fig. 3.

The AFM and SEM images revealed that cerium oxide nanoparticles appear elliptical and rod-shaped (Fig. 3a, b). The characteristic peaks for cerium and oxygen observed on the EDX spectrum confirm the formation of cerium oxide nanoparticles (Fig. 3c). Also, signal from carbon caused by polyphenol groups and other C-containing compounds in rapeseed meal was displayed. In addition, the presence of the S signal can be explained as the residue of the sulfate groups, whereas the Si signal originates from the substrate of the silicon wafer. Other impurities were not detected (Fig. 3c).

The UV–Vis spectrum (Fig. 1) and AFM and SEM-EDX analyses (Fig. 3) demonstrated the formation of cerium oxide nanoparticles.

Antioxidant Capacity of Real Samples

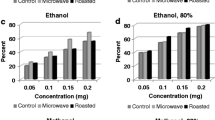

The AC of rapeseed, white flakes, and meal was determined by a new CeONP method and compared with the results obtained by the AgNP assay (Table 1).

The AC results of the studied samples indicate significant differences (Duncan test, Table 1), although the AC values of rapeseed and meal methanolic extracts determined by the AgNP method did not differ significantly. Moreover, insignificant differences between the CeONP and AgNP results for extracts of rapeseed and meal, respectively, prepared in 50 % methanol and water were observed. Also, the ACs of methanolic and aqueous extracts of meal analyzed by the novel CeONP method were not significantly different (Duncan test, p > 0.05).

It is noteworthy that the CeONP values (1037–3012 μmol SA 100 g−1) were significantly lower in comparison with the AgNP results (3859–12,534 μmol SA 100 g−1) for the examined extracts. This fact can be explained by the analyzed extracts containing antioxidant compounds more capable of reducing Ag+ to silver nanoparticles than Ce4+ to cerium oxide nanoparticles, although the applied methods (AgNP and CeONP) are based on the same reaction mechanism and measure the ability of rapeseed antioxidants to transfer one electron to reduce silver and cerium(IV) ions, respectively, which form the colored silver and cerium oxide nanoparticles. However, the formation of silver and cerium oxide nanoparticles depends on the concentration, oxidation potential, and chemical structure of antioxidants, as well as the reaction medium conditions.

The water extract of rapeseed revealed the lowest CeONP and AgNP values, while the ACs of white flakes and meal determined by both analytical methods were the lowest for 50 % methanolic extracts (Table 1). On the other hand, the methanolic extracts of rapeseed, white flakes, and meal presented the highest CeONP (1304–3012 μmol SA 100 g−1) and AgNP (9771–12,534 μmol SA 100 g−1) values. This suggests that methanol was the most effective solvent for the extraction of antioxidants from the studied samples; thus, the AC did not increase proportionally with solvent polarity. For comparison, the AC values of water extracts of herbal and tea samples determined by CERAC assay and ceria sensors varied from 9000 to 105,000 μmol 100 g−1 depending on the type of sample and its variety (Ozyurt et al. 2007; Sharpe et al. 2013). Although, Özyürek et al. (2012) obtained significantly lower AC results (200–3400 μmol 100 g−1) for some commercial fruit juices applying the SNPAC method based on the reduction of Ag+ ions in the presence of citrate-stabilized silver seeds. Moreover, in our previous reports, 50 % methanolic extracts of different rapeseed cultivars revealed AgNP values (5261–9462 μmol SA 100 g−1) similar to that (8629 μmol SA 100 g−1) for the studied winter open-pollinated rapeseed variety (Szydłowska-Czerniak et al. 2012; Szydłowska-Czerniak and Tułodziecka 2013). However, the AgNP values of the methanolic extracts of rapeseed (10,129 μmol SA 100 g−1) and meal (9771 μmol SA 100 g−1) were higher in comparison with those (7350 and 8830 μmol SA 100 g−1, respectively) obtained previously (Szydłowska-Czerniak et al. 2012). On the contrary, the aqueous extract of rapeseed had a somewhat lower AgNP value (5287 μmol SA 100 g−1) than earlier reported (5720 μmol SA 100 g−1; Szydłowska-Czerniak et al. 2012). Moreover Szydłowska-Czerniak et al. (2012) found about two times higher the AgNP for meal prepared in 50 % methanol and water (10,560 and 7180 μmol SA 100 g−1, respectively).

It is noteworthy that the RSD values for the novel CeONP method (1.2–3.9 %) were comparable to those obtained by the AgNP (0.5–4.2 %) assay. These results suggest that the used analytical methods based on metal oxide and metal nanoparticle formation can be applicable to the determination of the total antioxidant potential of rapeseed and its by-products, with good repeatability.

For comparison, Ozyurt et al. (2007) calculated a higher value of RSD = 6.62 % during the AC determination of the water extract of nettle by the CERAC method, whereas similar RSD results (1.4–5.0 %) were found for nettle, rosehip extracts, and various teas analyzed by the modified CERAC method and spectrofluorometric method based on Ce(IV) reduction (Ozyurt et al. 2010, 2011).

Also, a recovery test was performed for the accuracy evaluation of the new CeONP method. The recovery identifies a ratio between the quantity of analyte, experimentally determined in known concentration material, and the expected value. The results of the recovery test were listed in Table 2.

The recovery efficiency of sinapic acid added to methanolic, 50 % methanolic, and aqueous extracts of rapeseed, white flakes, and meal ranged between 95.8 % for the aqueous extract of rapeseed and 103.3 % for 50 % methanolic extract of meal (Table 2). These results indicate that the AC can be determined with good accuracy by the proposed CeONP method.

Also, Özyürek et al. (2012) and Szydłowska-Czerniak et al. (2012) calculated similar mean recoveries (92.3–104.6 %) for the AC of green tea, olive oil, as well as ethanolic, 50 % methanolic, and aqueous extracts of rapeseed and its products analyzed by the AgNP method.

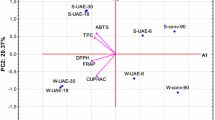

Correlation Between the CeONP and AgNP Methods

The relationship between the AC of the studied extracts of rapeseed, white flakes, and meal determined by both analytical methods based on the formation of cerium oxide and silver nanoparticles was estimated using regression analysis. The obtained AC results suggest that there are high positive correlations between the novel CeONP and AgNP assays (r = 0.9413, r = 0.9999, and r = 0.9505 for methanolic, 50 % methanolic, and aqueous extracts, respectively).

Also, the AC analyzed by the proposed CeONP assay and the results for all the studied extracts obtained by the AgNP method were correlated significantly (r = 0.8189, p = 0.0069).

This can be explained by the fact that all examined extracts were rich sources of antioxidants capable of the reduction of Ce(IV) and Ag(I) to suitable nanoparticles at the same time, which can be indicated by the characteristic bands in visible range.

For comparison, significantly lower correlation coefficients for the relationships between the CERAC–CUPRAC and CERAC–ABTS results (r = 0.666 and r = 0.731, respectively) of nine antioxidant compounds were calculated by Ozyurt et al. (2007). Also, lower values of r = 0.5971–0.9149 between the AgNP and FRAP, DPPH, and total phenolic content in different extracts of rapeseed, flakes, press cake, and meal were demonstrated in our previous papers (Szydłowska-Czerniak et al. 2012; Szydłowska-Czerniak and Tułodziecka 2013). However, a higher correlation coefficient (r = 0.936) was found between the silver nanoparticle-based (SNPAC) and the CUPRAC methods (Özyürek et al. 2012).

Conclusion

A novel spectrophotometric CeONP method for the AC evaluation of rapeseed and its by-products based on the generation of cerium oxide nanoparticles was developed for the first time. The redox reaction produces non-stoichiometric cerium oxide nanoparticle solutions at room temperature and pH 5.6, and their optical absorption peak was detected at 510 nm. However, the formation of cerium oxide nanoparticles depends on the time, temperature, pH of the reaction mixture, and the concentration of cerium(IV) sulfate. The proposed CeONP method is simple, rapid, and low-cost, but precise, accurate, and sensitive, and it can be used by industrial laboratories equipped with a spectrophotometer. The novel CeONP method revealed a satisfactory, intra-day precision (RSD = 1.2–3.9 %) comparable to that of the AgNP method (RSD = 0.5–4.2 %) and higher sensitivity (ε = 1.24 × 104 and 4.1 × 103 L mol−1 cm−1 for the CeONP and AgNP methods for sinapic acid, respectively).

Therefore, the new CeONP method is an alternative procedure for these based on the formation of metal nanoparticles such as AgNP, and it can be applied by oil industry laboratories for the AC assessment of oilseeds, semi-products, final products, and by-products.

References

Bumajdad A, Eastoe J, Mathew A (2009) Cerium oxide nanoparticles prepared in self-assembled systems. Adv Colloid Interface Sci 147–148:56–66

Choleva TG, Kappi FA, Giokas DL, Vlessidis AG (2015) Paper-based assay of antioxidant activity using analyte-mediated on-paper nucleation of gold nanoparticles as colorimetric probes. Anal Chim Acta 860:61–69

Khattab RY, Arntfield SD (2009) Functional properties of raw and processed canola meal. LWT – Food Sci Technol 42:1119–1124

Kimber DS, McGregor DI (1995) The species and their origin, cultivation and world production. In: Kimber DS, McGregor DI (eds) Brassica oilseeds: production and utilization. CABI Publishing, Wallingford, UK, pp 1–9

Korsvik C, Patil S, Seal S, Self WT (2007) Superoxide dismutase mimetic properties exhibited by vacancy engineered ceria nanoparticles. Chem Commun 10:1056–1058

Lin M, Fu ZY, Tan HR, Tan JPY, Ng SC, Teo E (2012) Hydrothermal synthesis of CeO2 nanocrystals: Ostwald ripening or oriented attachment? Cryst Growth Des 12:3296–3303

Liu Q, Liu H, Yuan Z, Wei D, Ye Y (2012) Evaluation of antioxidant activity of chrysanthemum extracts and tea beverages by gold nanoparticles-based assay. Colloid Surface B 92:348–352

Maenz DD (2007) Canola protein concentrate for use as a high-valued animal feed ingredient. Feed and Industrial Raw Material: Feed 5:274–276

Masui T, Hirai H, Imanaka N, Adachi G, Sakata T, Mori H (2002) Synthesis of cerium oxide nanoparticles by hydrothermal crystallization with citric acid. J Mater Sci Lett 21:489–491

Naczk M, Amarowicz R, Sullivan A, Shahidi F (1998) Current research developments on polyphenolics of rapeseed/canola: a review. Food Chem 62:489–502

Naganuma T, Traversa E (2012) Stability of the Ce3+ valence state in cerium oxide nanoparticle layers. Nanoscale 4:4950–4953

Nesi N, Delourme R, Brégeon M, Falentin C, Renard M (2008) Genetic and molecular approaches to improve nutritional value of Brassica napus L. seed. C R Biol 331:763–771

Okuda M, Suzumoto Y, Yamashita I (2011) Bioinspired synthesis of homogenous cerium oxide nanoparticles and two- or three-dimensional nanoparticle arrays using protein supramolecules. Cryst Growth Des 11:2540–2545

Ornatska M, Sharpe E, Andreescu D, Andreescu S (2011) Paper bioassay based on ceria nanoparticles as colorimetric probes. Anal Chem 83:4273–4280

Özyürek M, Güngör N, Baki S, Güçlü K, Apak R (2012) Development of a silver nanoparticle-based method for the antioxidant capacity measurement of polyphenols. Anal Chem 84:8052–8059

Ozyurt D, Demirata B, Apak R (2007) Determination of total antioxidant capacity by a new spectrophotometric method based on Ce(IV) reducing capacity measurement. Talanta 71:1155–1165

Ozyurt D, Demirata B, Apak R (2010) Modified cerium(IV)-based antioxidant capacity (CERAC) assay with selectivity over citric acid and simple sugars. J Food Compos Anal 23:282–288

Ozyurt D, Demirata B, Apak R (2011) Determination of total antioxidant capacity by a new spectrofluorometric method based on Ce(IV) reduction: Ce(III) fluorescence probe for CERAC assay. J Fluoresc 21:2069–2076

Papadopoulos K, Triantis T, Yannakopoulou E, Nikokavoura A, Dimotikali D (2003) Comparative studies on the antioxidant activity of aqueous extracts of olive oils and seed oils using chemiluminescence. Anal Chim Acta 494:41–47

Pelle FD, González MC, Sergi M, Del Carlo M, Compagnone D, Escarpa A (2015a) Gold nanoparticles-based extraction-free colorimetric assay in organic media: an optical index for determination of total polyphenols in fat-rich samples. Anal Chem 87:6905–6911

Pelle FD, Vilela D, González MC, Sterzo CL, Compagnone D, Del Carlo M, Escarpa A (2015b) Antioxidant capacity index based on gold nanoparticles formation. Application to extra virgin olive oil samples. Food Chem 178:70–75

Roy N, Laskar RA, Sk I, Kumari D, Ghosh T, Begum NA (2011) A detailed study on the antioxidant activity of the stem bark of Dalbergia sissoo Roxb., an Indian medicinal plant. Food Chem 126:1115–1121

Samiee S, Goharshadi EK (2012) Effects of different precursors on size and optical properties of ceria nanoparticles prepared by microwave-assisted method. Mater Res Bull 47:1089–1095

Scampicchio M, Wang J, Blasco AJ, Arribas AS, Mannino S, Escarpa A (2006) Nanoparticle-based assays of antioxidant activity. Anal Chem 78:2060–2063

Shahidi F, Ho C-T (2005) Phenolics in food and natural health products: an overview. In: Shahidi F, Ho C-T (eds) Phenolic compounds in foods and natural health products. American Chemical Society, Washington, DC, pp 1–8

Sharpe E, Frasco T, Andreescu D, Andreescu S (2013) Portable ceria nanoparticle-based assay for rapid detection of food antioxidants (NanoCerac). Analyst 138:249–262

Szydłowska-Czerniak A, Tułodziecka A (2013) Comparison of a silver nanoparticle-based method and the modified spectrophotometric methods for assessing antioxidant capacity of rapeseed varieties. Food Chem 141:1865–1871

Szydłowska-Czerniak A, Tułodziecka A, Szłyk E (2012) A silver nanoparticle-based method for determination of antioxidant capacity of rapeseed and its products. Analyst 137:3750–3759

Szydłowska-Czerniak A, Łaszewska A, Tułodziecka A (2015) A novel iron oxide nanoparticle-based method for the determination of the antioxidant capacity of rapeseed oils at various stages of the refining process. Anal Methods 7:4650–4660

Tura D, Gigliotti C, Pedò S, Failla O, Bassi D, Serraiocco A (2007) Influence of cultivar and site of cultivation on levels of lipophilic and hydrophilic antioxidants in virgin olive oils (Olea europea L.) and correlations with oxidative stability. Sci Hortic 112:108–119

Vilela D, González MC, Escarpa A (2012) Gold-nanosphere formation using food sample endogenous polyphenols for in-vitro assessment of antioxidant capacity. Anal Bioanal Chem 404:341–349

Vilela D, González MC, Escarpa A (2014) (Bio)-synthesis of Au NPs from soy isoflavone extracts as a novel assessment tool of their antioxidant capacity. RSC Adv 4:3075–3081

Vilela D, Castañeda R, González MC, Mendoza S, Escarpa A (2015a) Fast and reliable determination of antioxidant capacity based on the formation of gold nanoparticles. Microchim Acta 182:105–111

Vilela D, González MC, Escarpa A (2015b) Nanoparticles as analytical tools for in-vitro antioxidant-capacity assessment and beyond. Trends Anal Chem 64:1–16

Vuorela S, Meyer AS, Heinonen M (2004) Impact of isolation method on the antioxidant activity of rapeseed meal phenolics. J Agric Food Chem 52:8202–8207

Wang JP, Li NB, Luo HQ (2008) Chemiluminescence determination of ferulic acid by flow-injection analysis using cerium(IV) sensitized by rhodamine 6G. Spectrochim Acta A 71:204–208

Yan M, Wei W, Zuoren N (2007) Influence of pH on morphology and formation mechanism of CeO2 nanocrystalline. J Rare Earths 25:53–57

Yoshie-Stark Y, Wada Y, Wäsche A (2008) Chemical composition, functional properties, and bioactivities of rapeseed protein isolates. Food Chem 107:32–39

Zougagh M, Salghi R, Dhair S, Rios A (2011) Nanoparticle-based assay for the detection of virgin argan oil adulteration and its rapid quality evaluation. Anal Bioanal Chem 399:2395–2405

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

This work was supported by the National Science Center of Poland grant no. DEC-2013/09/N/NZ9/01451.

Conflict of Interest

Agnieszka Tułodziecka declares that she has no conflict of interest. Aleksandra Szydłowska-Czerniak declares that she has no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed Consent

The authors named in the manuscript are entitled to the authorship and have approved the final version of the submitted manuscript.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Tułodziecka, A., Szydłowska-Czerniak, A. Determination of Total Antioxidant Capacity of Rapeseed and Its By-Products by a Novel Cerium Oxide Nanoparticle-Based Spectrophotometric Method. Food Anal. Methods 9, 3053–3062 (2016). https://doi.org/10.1007/s12161-016-0473-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-016-0473-y