Abstract

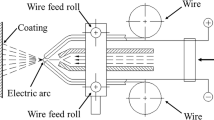

Wire arc spraying is an economically attractive thermal spray process that is especially interesting for the protection of large-scale parts or constructions. This study presents the results of the development and investigation of a number of cored wires based on the Fe-Cr-Al system with minor addition of alloying elements (B, Mn, Ni, Si, Ti, Mg, etc.). The microstructure of the coatings, their electrochemical behavior, and isothermal oxidation performance over a temperature range of 20-700 °C were investigated. Erosion resistance at elevated temperatures was determined with a laboratory test unit under test conditions that have simulated the work conditions in fossil-fuel-fired boilers. It was established that the oxidation resistance and the gas-abrasive wear resistance of arc-sprayed coatings depend mostly on the coating microstructure and homogeneity of element distribution rather than on the general alloying level and microhardness of the coating. A new parameter for coating characterization, namely, the coefficient of chemical microheterogeneity, K CMH, is introduced to quantify this influence. Formation of the coating microstructure at elevated temperatures and its influence on the protection ability of the coating are discussed.

Similar content being viewed by others

References

C.S. Dallaire, H. Levert, and J.-G. Legoux, Erosion Resistance of Arc-Sprayed Coatings to Iron Ore at 25 and 315 °C, J. Therm. Spray Technol., 2001, 10(2), p 337-350

D.J. Branagan, W.D. Swank, and D.C. Haggard, Wear Resistant Amorphous and Nanocomposite Steel Coatings, Metall. Mater. Trans., 2001, 32(10), p 2615-2621

D.E. Alman, and J.W. Newkirk, Powder Metallurgy Alloys and Particulate Materials for Industrial Application, The Minerals, Metals, and Materials Society, Warrendale, PA, 2001, p 111-122

K. Venugopal and M. Agrawal, Evaluation of Arc Sprayed Coatings for Erosion Protection of Tubes in Atmospheric Fluidised Bed Combustion (AFBC) Boilers, Wear, 2008, 264(1-2), p 139-145

S.-G. Liu, J.-M. Wu, and S.-C. Zhang, High Temperature Erosion Properties of Arc-Sprayed Coatings Using Various Cored Wires Containing Ti-Al Intermetallics, Wear, 2007, 262(5-6), p 555-561

H. Pokhmurs’ka, N. Chervins’ka, M. Student, and Kh. Zadorozhna, Effect of the Laser Fusion of Electrometallised Coatings of the Fe-Cr-B-Al System on Their Corrosion Resistance, Mater. Sci., 2006, 42(6), p 837-842

M.M. Student, H.V. Pokhmurs’ka, V.V. Hvozdets’kyi, M.Ya. Holovchuk, and M.S. Romaniv, Effect of High-Temperature Corrosion on the Gas-Abrasive Resistance of Electric-Arc Coatings, Mater. Sci., 2009, 45(4), p 481-489

H. Pokhmurska, B. Wielage, T. Grund, V. Pokhmurski, and M. Student, High Temperature Oxidation Behavior of Coatings Obtained by Arc Spraying the Cored Wires Based on Fe-Cr-B-Al System, Proc. Europ. Corrosion Congress: Managing Corrosion for Sustainability, Eurocorr 2008, 2008, CD-Edition, p 5

B.Q. Wang, G.Q. Geng, and A.V. Levy, Erosion Resistance of Arc-Sprayed Coatings, Wear, 1992, 159(3), p 233-235

W. Milewski, A. Olbrych, S. Pawlik, and T. Borowski, Arc-Sprayed Heat-Resistant Fe-Cr-Al, Proc. II International Conference of Thermal Spraying: Industrial Metallization—Today and To-Morrow, Vol. 9, 2009, p 45-48 (in Polish)

H. Pokhmurska, B. Wielage, T. Grund, M. Student, and Y. Sirak, Arc-Sprayed Coatings Obtained from Iron Based Cored Wires Under High-Temperature Abrasive Wear Conditions, Proc. Int. Thermal Spray Conf.: Thermal Spray Crossing Borders, Maastricht, 2008, DVS-Verlag GmbH, p 338-341

Y. Kawahara, Application of High Temperature Corrosion-Resistant Materials and Coatings Under Severe Corrosive Environment in Waste-to-Energy Boilers, J. Therm. Spray Technol., 2007, 16(2), p 202-213

S.-H. Lee, N.J. Themelis, and M.J. Castaldi, High-Temperature Corrosion in Waste-to-Energy Boilers, J. Therm. Spray Technol., 2007, 16(1), p 104-110

D.J. Branagan and Y. Tang, Developing Extreme Hardness (>15 GPa) in Iron Based Nanocomposites, Composites, 2002, 33(6), p 855-859

E. Badisch, C. Katsich, and H. Winkelmann, Wear Behaviour of Hardfaced Fe-Cr-C Alloy and Austenitic Steel Under 2-Body and 3-Body Conditions at Elevated Temperature, Tribol. Int., 2010, 2, p 214-228

M. Student, Yu. Dzioba, V. Hvozdets’kyi, H. Pokhmurska, B. Wielage, and T. Grund, High-Temperature Corrosion of Electric-Arc Coatings Sprayed from Powder Core Wires Based on the Fe-Cr-B-Al System, Mater. Sci., 2008, 44(5), p 693-699

V. Pokhmurskij, M. Student, I. Sydorak, H. Pokhmurska, and V. Dovhunyk, Wear Resistance Arc-Sprayed Coatings from Powder Wires, Proc. Int. Thermal Spray Conf & Exposition, ITSC’2002, 2002 DVS/IIW/ASM-TSS, p 559-562

H.-D. Steffens, H. Drzeniek, and Z. Badiak, Wear Resistant Composite Coatings Produced by Arc Spraying Using Cored Wires, Thermal Spray Technology—New Ideas and Processes, ASM International, Materials Park, 1988, p 331-336

S. Dallaire, Hard Arc-Sprayed Coating with Enhanced Erosion and Abrasion Wear Resistance, J. Therm. Spray Technol., 2001, 10(3), p 511-519

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pokhmurskii, V., Student, M., Gvozdeckii, V. et al. Arc-Sprayed Iron-Based Coatings for Erosion-Corrosion Protection of Boiler Tubes at Elevated Temperatures. J Therm Spray Tech 22, 808–819 (2013). https://doi.org/10.1007/s11666-013-9921-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-013-9921-z