There are 88 waste-to-energy (WTE) plants in the U.S. and over 600 worldwide. In total, they combust close to 143 million metric tons of municipal solid wastes (MSW) and generate about 45 billion kW · h of electricity and an equal amount of thermal energy for district heating and industrial use. The presence of various impurities, especially HCl and chloride salts, in the combustion gases results in much higher corrosion rates of boiler tubes and has led to the development of special alloys and also metal protection techniques, including high velocity oxygen fuel (HVOF) sprayed coatings. This study examines the corrosion mechanisms in WTE boilers and summarizes the findings of a corrosion survey of several WTE facilities in the U.S. The study also examines existing and potential methods for reducing corrosion problems.

Similar content being viewed by others

Notes

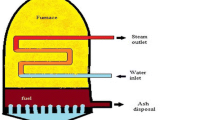

Waterwall: The wall of the main combustion chamber is covered by a gas tight membrane consisting of metal tubes joined by means of metal strips welded between the tubes. Water is flowing through the tubes that are heated mostly by radiation and convection from the combustion gases.

Superheater: Steam running through the superheater tubes is heated to temperatures well above the saturation point. Therefore, metal temperatures are much higher than waterwall tubes.

Passes in the boiler industry denote the interconnected heat transfer vessels, e.g., first pass is the waterwall surfaces in the combustion chamber.

References

N.J. Themelis, Status of the Global WTE Industry, Waste Management World, 2003.

N.J. Themelis and P. Ulloa, Capture and Utilization of Landfill Gas, Renewable Energy, 2005.

P. Rademarkers, W. Hesseling, and J. Wetering, Review on Corrosion in Waste Incinerators, and Possible Effect of Bromine. TNO Industrial Technology, 2002.

D.O. Albina. Theory and Experience on Corrosion of Waterwall and Superheater Tubes of Waste-To-Energy Facilities. Master thesis, Columbia University, 2005

N.J. Themelis, Chlorine Balance in a Waste-To-Energy Facility, Earth Engineering Center, Columbia University, 2005

Kawahara Y. (2002) High Temperature Corrosion Mechanisms and Effect of Alloying Elements for Materials Used in Waste Incineration Environment, Corros. Sci. 44(2):223

Holcomb G.R. (2000) Hot Corrosion in a Temperature Gradient, Mater. Corros. 51(8):564-569

B.S. Covino, G.R. Holcomb, S.D. Cramer, S.J. Bullard, M. Ziomek-Moroz, and M.L. White, Corrosion in a Temperature Gradient, Albany Research Center, U.S. Department of Energy, Albany, OR

Y. Kawahara, K. Takahashi, Y. Nakagawa, T. Hososda, and T. Mizuko, Demonstration Test of New Corrosion-Resistant Superheater Tubings in a High-Efficiency Waste-To-Energy Plant, Corrosion 2000, 2000, p 265

B. Adams, K. Peeters, D. Earaerts, H.S.W. Diederen, and J.P.F. Wijnhoven, Seghers Boiler Prism: A Proven Primary Measure against High Temperature Boiler Corrosion, Seghers Scientec Matrix, Willebroek, Belgium

H. Zwahr, Ways to Improve the Efficiency of Waste to Energy Plants for the Production of Electricity, Heat and Reusable Materials, Proceedings of the 11th North America Waste to Energy Conference, Florida, 2003

Spiegel W. (2002) Praxisnahe Unterstutzung der Betreiber bei der Optimierung und nachhaltigen Nutzung der bayerischen MV-Anlagen. CheMin GmbH, Augsburg, Germany

Wilson A., Forsberg U., Noble J. (1997) Experience of Composite Tubes in Municipal Waste Incinerators, Corrosion 97:153

Solomon N.G. (1998) Erosion-Resistant Coatings for Fluidized Bed Boilers, Mater. Perform., 37(2):38-43

Uusitalo M.A., Vuoristo P.M.J., Mantyla T.A. (2002) Elevated Temperature Erosion-Corrosion of Thermal Sprayed Coatings in Chlorine Containing Environments. Wear 252(7-8):586-594

Higuera V., Belzunce F.J., Carriles A., Poveda S. (2002) Influence of the Thermal-spray Procedure on the Properties of a Nickel-Chromium Coating. J. Mater. Sci. 37(3):649-654

H.Y. Al-Fadhli, J. Stokes, M.S.J. Hashmi, and B.S. Yilbas, The Erosion-Corrosion Behaviour of High Velocity Oxy-Fuel (Hvof) Thermally Sprayed Inconel-625 Coatings on Different Metallic Surfaces, Surf. Coatings Technol., in press

Y. Fukuda, K. Kawahara, and T. Hosoda, Application of High Velocity Flame Sprayings for Superheater Tubes in Waste Incinerators, Corrosion 2000, 2000, p 00264.1-00264.14

J.D. Martin and K. Robbins, Evaluation of Chloride Corrosion Reduction with Chemical Additives at Maine Energy Recovery, Proceedings of the 13th North America Waste to Energy Conference, Orlando, FL, 2005

C.R. Smyriniotis and C. Collier, Slag Inhibition Success Utilizing Targeted In-Furance Injection at Western Farmers Cooperative Hugo Station, PRB Coal Users’ Group Annual Meeting, Electric Power 2004 Conference, Baltimore, MD, 2004

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lee, SH., Themelis, N.J. & Castaldi, M.J. High-Temperature Corrosion in Waste-to-Energy Boilers. J Therm Spray Tech 16, 104–110 (2007). https://doi.org/10.1007/s11666-006-9005-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-006-9005-4