Abstract

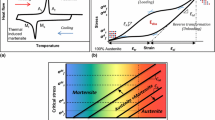

In this study, the hot deformation behavior of Ni49Ti36Hf15 alloy was investigated. Compression tests were carried out at temperatures ranging from 800 to 1100 °C and at the strain rates of 0.001–1/s. The peak stress decreases with increasing deformation temperature and decreasing strain rate, a behavior which can be described by plotting the Zener-Hollomon parameter as a function of stress. It was realized that dynamic recrystallization (DRX) was responsible for flow softening. Most of the samples exhibited typical DRX stress-strain curves with a single peak stress followed by a gradual fall down stress. Microstructure evolution showed that new recrystallized grains formed in the vicinity of grain boundaries. The hyperbolic-sine-type constitutive model of Ni49Ti36Hf15 alloy was obtained to provide basic data for determining reasonable hot-forming process. The activation energy for hot deformation of the Ni49Ti36Hf15 alloy was close to 410 kJ/mol.

Similar content being viewed by others

References

X.L. Meng, Y.F. Zheng, Z. Wang, and L.C. Zhao, Effect of Aging on the Phase Transformation and Mechanical Behavior of Ti36Ni49Hf15 High Temperature Shape Memory Alloy, Scr Mater, 2000, 42, p 341–348

X.L. Meng, Y.F. Zheng, Z. Wang, W. Cai, and L.C. Zhao, Phase Transformation and Precipitation in Aged Ti-Ni-Hf High-Temperature Shape Memory Alloys, Mater. Sci. Eng., A, 2006, 438(440), p 666–670

G.S. Firstov, J.V. Humbeeck, and Y.N. Koval, High-Temperature Shape Memory Alloys: Some Recent Developments, Mater. Sci. Eng., A, 2004, 378, p 2–10

P.L. Potapov, A.V. Shelyakov, A.A. Gulyaev, E.L. Svistunova, N.M. Matveeva, and D. Hodgson, Effect of Hf on the Structure of Ni-Ti Martensitic Alloys, Mater. Lett., 1997, 32, p 247–250

X.L. Meng, W. Cai, L.M. Wang, Y.F. Zheng, L.C. Zhao, and L.M. Zhou, Microstructure of Stress-Induced Martensite in a Ti-Ni-Hf High Temperature Shape Memory Alloy, Scr Mater, 2001, 45, p 1177–1182

W. Cai, X.L. Meng, and L.C. Zhao, Recent Development of TiNi-Based Shape Memory Alloys, Curr. Opin. Solid State Mater. Sci., 2005, 9, p 296–302

Y.Q. Wang, Y.F. Zheng, and L.C. Zhao, The Tensile Behavior of Ti36Ni49Hf15High Temperature Shape Memory Alloy, Scr Mater, 1999, 40, p 1327–1331

C. Craig Wojcik, Properties and Heat Treatment of High Transition Temperature Ni-Ti-Hf Alloys, Mater. Eng. Perform., 2009, 18, p 511–516

X.L. Meng, W. Cai, Y.D. Fu, Q.F. Li, J.X. Zhang, and L.C. Zhao, Shape-Memory Behaviors in an Aged Ni-Rich TiNiHf High Temperature Shape-Memory Alloy, Intermetallics, 2008, 16, p 698–705

P.E. Thoma and J.J. Boehm, Effect of Composition on the Amount of Second Phase and Transformation Temperatures of NixTi90-xHf10 Shape Memory Alloys, Mater. Sci. Eng., A, 1999, 273, p 385–389

Y. Tong, F. Chen, B. Tian, and Y. Zheng, Microstructure and Martensitic Transformation of Ti49Ni51-xHfx High Temperature Shape Memory Alloys, Mater. Lett., 2009, 63, p 1869–1871

S. Besseghini, E. Villa, and A. Tuissi, Ni-Ti-Hf Shape Memory Alloy: Effect of Aging and Thermal Cycling, Mater. Sci. Eng., A, 1999, 273, p 390–394

S. Han, W. Zou, S. Jin, Z. Zhang, and D. Yang, The Studies of the Martensite Transformations in a Ti36Ni49Hf15 Alloy, Scr Mater, 1995, 32, p 1441–1446

K. Dehghani and A.A. Khamei, Hot Deformation Behavior of 60Nitinol (Ni60 wt%-Ti40 wt%) Alloy Experimental and Computational Studies, Mater. Sci. Eng., A, 2010, 527, p 684–690

E.I. Poliak and J.J. Jonas, Initiation of Dynamic Recrystallization in Constant Strain Rate Hot Deformation, ISIJ Int., 2003, 43, p 684–691

T. Sakai and J.J. Jonas, Dynamic Recrystallization: Mechanical and Microstructural Considerations, Acta Metall., 1984, 32, p 189–209

M.J. Luton and C.M. Sellars, Dynamic Recrystallization in Nickel and Nickel-Iron Alloys During Hot Temperature Deformation, Acta Metall., 1969, 17, p 1033–1043

X. He, Zh Yu, and X. Lai, A Method to Predict Flow Stress Considering Dynamic Recrystallization During Hot Deformation, Mater. Sci., 2008, 44, p 760–764

H.J. Mcqueen and N.D. Ryan, Constitutive Analysis in Hot Working, Mater. Sci. Eng., A, 2002, 322, p 43–63

Y.C. Lin, M.S. Chen, and J. Zhong, Constitutive Modeling for Elevated Temperature Flow Behavior of 42CrMo Steel, Mater. Sci., 2008, 42, p 470–477

D. Samantary and S. Mandal, Constitutive Analysis to Predict High Temperature Flow Stress in Modified 9Cr-1Mo Steel, Mater. Des., 2010, 31, p 981–984

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belbasi, M., Salehi, M.T. & Mousavi, S.A.A.A. Hot Deformation Behavior of NiTiHf Shape Memory Alloy Under Hot Compression Test. J. of Materi Eng and Perform 21, 2594–2599 (2012). https://doi.org/10.1007/s11665-012-0275-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0275-3