Abstract

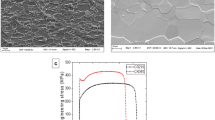

In this study, the electric resistance spot welding process was applied to zinc-coated steel sheets used in automotive industry. Spot welding parameters namely, electrode form, electrode material, and electrode force were stayed constant, and welding current and welding time have been changed to detect the optimum welding parameters for maximum joint strength. Using 4, 5, 6, 7, and 8 kA welding currents and 5, 10, 15, 20, and 25 cycles welding times 1.0-1.0 mm sheets were spot welded to prepare samples. These spot-welded joints were then exposed to uniaxial tensile test, and tensile-shear and tensile-peel forces prior to breaking were determined. In addition, microstructures were detected by SEM and micro-hardness was measured from different regions of resistance spot-welded samples and recommendations showing the optimum welding parameters were given to users.

Similar content being viewed by others

References

Safety and health fact sheet no. 21, American Welding Society, 1999

S. Aslanlar, The Effect of Nucleus Size on Mechanical Properties in Electrical Resistance Spot Welding of Sheets Used in Automotive Industry, Mater. Des., 2006, 27, p 125–131

R. Qiu, H. Shi, H. Yu, K. Zhang, Y. Tu, and S. Satonaka, Effects of Electrode Force on the Characteristic of Magnesium Alloy Joint Welded by Resistance Spot Welding with Cover Plates, Mater. Manuf. Process., 2010, 25(11), p 1304–1308

M. Goodarzi, S.P.H. Marashi, and M. Pouranvari, Dependence of Overload Performance on Weld Attributes for Resistance Spot Welded Galvanized Low Carbon Steel, J. Mater. Process. Technol., 2009, 209, p 4379–4384

P. Marashi, M. Pouranvari, S. Amirabdollahian, A. Abedi, and M. Goodarzi, Microstructure and Failure Behavior of Dissimilar Resistance Spot Welds Between Low Carbon Galvanized and Austenitic Stainless Steels, Mater. Sci. Eng., A, 2008, 480, p 175–180

G. Mozurkewich, B. Ghaffari, and T.J. Potter, Spatially Resolved Ultrasonic Attenuation in Resistance Spot Welds: Implications for Nondestructive Testing, Ultrasonics, 2008, 48, p 343–350

S.M. Darwish, M.S. Soliman, and A.M. AI-Fahead, Characteristics and Variables of Spot Welding and Weldbonding Biomaterials, Mater. Manuf. Process., 1997, 12(2), p 175–186

S.M. Hamidinejad, F. Kolahan, and A.H. Kokabi, The Modeling and Process Analysis of Resistance Spot Welding on Galvanized Steel Sheets Used in Car Body Manufacturing, Mater. Des., 2011. doi:10.1016/j.matdes.2011.06.064

M. Vural, A. Akkus, and B. Eryurek, Effect of Welding Nugget Diameter on the Fatigue Strength of the Resistance Spot Welded Joints of Different Steel Sheets, J. Mater. Process. Technol., 2006, 176, p 127–132

L. Mei, G. Chen, X. Jin, Y. Zhang, and Q. Wu, Research on Laser Welding of High-Strength Galvanized Automobile Steel Sheets, Opt. Laser Eng., 2009, 47, p 1117–1124

C.H. Kim, Y.N. Ahn, and J.H. Kim, CO2 Laser-Micro Plasma Arc Hybrid Welding for Galvanized Steel Sheets, Trans. Nonferrous Met. Soc., 2011, 21, p 47–53

H. Tang, W. Hou, and S.J. Hu, Influence of Welding Machine Mechanical Characteristics on the Resistance Spot Welding Process and Weld Quality, Weld. Int., 2003, 5, p 116–124

X.Q. Zhang, G.L. Chen, and Y.S. Zhang, Characteristics of Electrode Wear in Resistance Spot Welding Dual-Phase Steels, Mater. Des., 2008, 29(1), p 279–283

K.L. Chatterjee and W. Waddell, Electrode Wear During Spot Welding of Coated Steels, Weld. Mater. Fabr., 1996, 3, p 110–114

S. Fukumoto, I. Lum, E. Biro, and D.R. Boomer, Effects of Electrode Degradation on Electrode Life in Resistance Spot Welding of Aluminum Alloy, Weld. Int., 2003, 5, p 11307–11312

R. Holiday, J. Parker, and N.T. Williams, Relative Contribution of Electrode Tip Growth Mechanisms in Spot Welding Zinc Coated Steels, Weld World, 1996, 37(4), p 186–193

M. Rashid, Some Tribological Influences on the Electrode-Worksheet Interface During Resistance Spot Welding of Aluminum Alloys, J. Mater. Eng. Perform., 2011, 20, p 456–462

Acknowledgment

The author wishes to thank Sakarya University Scientific Research Foundation (Project number: 2010-05-04-004) for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ozsarac, U. Investigation of Mechanical Properties of Galvanized Automotive Sheets Joined by Resistance Spot Welding. J. of Materi Eng and Perform 21, 748–755 (2012). https://doi.org/10.1007/s11665-012-0189-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-012-0189-0