Abstract

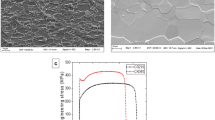

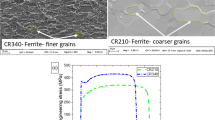

Resistance spot welding is one of the acknowledged spot joining processes which is predominantly used in the fabrication and assembling of parts in the automotive industry. In the present work, resistance spot welding of CR210, CR340 sheets (both galvanized) were conducted to evaluate the joint performance at varied heat inputs. RSW heat and time are varied within a range chosen based on preliminary trials. Lap shear test, micro-hardness, and microstructural evolution are used to determine the joint quality, morphology, and strength. Self-piercing riveting, which has gained popularity recently, is also performed on the same sheets. Finally, a lap shear test is conducted on SPR joints and compared to RSW joints. Preliminary results are brought forward and discussed.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Rana, P.K., Narayanan, R.G., Kailas, S.V.: Friction stir spot welding of AA5052-H32/HDPE/AA5052-H32 sandwich sheets at varying plunge speeds. Thin-Walled Struct. 138, 415–429 (2019). https://doi.org/10.1016/j.tws.2019.02.016

Briskham, P., Blundell, N., Han, L., Hewitt, R., Young, K., Boomer, D.: Comparison of self-pierce riveting, resistance spot welding and spot friction joining for aluminium automotive sheet. SAE Technical paper, 2006-01-0774 (2006). https://doi.org/10.4271/2006-01-0774

Eshtayeh, M.M., Hrairi, M., Mohiuddin, A.K.M.: Clinching process for joining dissimilar materials: state of the art. Int. J. Adv. Manuf. Technol. 82(1–4), 179–195 (2016). https://doi.org/10.1007/s00170-015-7363-0

He, X., Xing, B., Zeng, K., Gu, F., Ball, A.: Numerical and experimental investigations of self-piercing riveting. Int. J. Adv. Manuf. Technol. 69(1–4), 715–721 (2013). https://doi.org/10.1007/s00170-013-5072-0

Manladan, S.M., Yusof, F., Ramesh, S., Fadzil, M., Luo, Z., Ao, S.: A review on resistance spot welding of aluminum alloys. Int. J. Adv. Manuf. Technol. 90(1–4), 605–634 (2017). https://doi.org/10.1007/s00170-016-9225-9

Liu, Y., Li, H., Zhao, H., Liu, X.: Effects of the die parameters on the self-piercing riveting process. Int. J. Adv. Manuf. Technol. 105(7–8), 3353–3368 (2019). https://doi.org/10.1007/s00170-019-04567-4

Du, G., Xing, Y., Li, X.: Fatigue properties of self-piercing riveted multi-rivet joints in steel and aluminum sheets. Mater. Werkst. 50(12), 1495–1502 (2019). https://doi.org/10.1002/mawe.201800114

Deng, J.-H., Lyu, F., Chen, R.-M., Fan, Z.-S.: Influence of die geometry on self-piercing riveting of aluminum alloy AA6061-T6 to mild steel SPFC340 sheets. Adv. Manuf. 7(2), 209–220 (2019). https://doi.org/10.1007/s40436-019-00250-9

Li, D.: Influence of local surface texture by tool impression on the self-piercing riveting process and the static lap shear strength. J. Manuf. Process. 29, 298–309 (2017). https://doi.org/10.1016/j.jmapro.2017.08.003

Saha, D.C., Park, Y.-D.: A review on Al-Al/Al-steel resistance spot welding technologies for light weight vehicles. J. Weld. Join. 29(4), 35–40 (2011). https://doi.org/10.5781/KWJS.2011.29.4.397

Summerville, C., Adams, D., Compston, P., Doolan, M.: Nugget diameter in resistance spot welding: a comparison between a dynamic resistance based approach and ultrasound C-scan. Proc. Eng. 183, 257–263 (2017). https://doi.org/10.1016/j.proeng.2017.04.033

Aslanlar, S., Ogur, A., Ozsarac, U., Ilhan, E.: Welding time effect on mechanical properties of automotive sheets in electrical resistance spot welding. Mater. Des. 29(7), 1427–1431 (2008). https://doi.org/10.1016/j.matdes.2007.09.004

Aslanlar, S.: The effect of nucleus size on mechanical properties in electrical resistance spot welding of sheets used in automotive industry. Mater. Des. 27(2), 125–131 (2006). https://doi.org/10.1016/j.matdes.2004.09.025

Eisazadeh, H., Hamedi, M., Halvaee, A.: New parametric study of nugget size in resistance spot welding process using finite element method. Mater. Des. 31(1), 149–157 (2010). https://doi.org/10.1016/j.matdes.2009.06.042

Manladan, S.M., Abdullahi, I., Hamza, M.F.: A review on the application of resistance spot welding of automotive sheets. J. Eng. Technol. 10, 20 (2015)

Hayat, F.: The effects of the welding current on heat input, nugget geometry, and the mechanical and fractural properties of resistance spot welding on Mg/Al dissimilar materials. Mater. Des. 32(4), 2476–2484 (2011). https://doi.org/10.1016/j.matdes.2010.11.015

Rao, Z., Ou, L., Wang, Y., Wang, P.C., A self-piercing-through riveting method for joining of discontinuous carbon fiber reinforced nylon 6 composite. Compos. Struct. 237, 111841 (2020). https://doi.org/10.1016/j.compstruct.2019.111841

Wan, X., Wang, Y., Zhang, P.: Modelling the effect of welding current on resistance spot welding of DP600 steel. J. Mater. Process. Technol. 214(11), 2723–2729 (2014). https://doi.org/10.1016/j.jmatprotec.2014.06.009

Pouranvari, M.: Susceptibility to interfacial failure mode in similar and dissimilar resistance spot welds of DP600 dual phase steel and low carbon steel during cross-tension and tensile-shear loading conditions. Mater. Sci. Eng. A 546, 129–138 (2012)

Acknowledgements

Authors of this work are very grateful to central workshop of Mechanical Engineering department, IIT Guwahati and CAWJ Lab, Tata Steel for sample preparation, procurement of base materials and to carry out the experiments.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2023 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Gupta, S., Ganesh Narayanan, R., Das, S., Asati, B. (2023). Joining of Dissimilar Galvanized Steel Sheets by Resistance Spot Welding and Self-piercing Riveting. In: Ramesh Babu, N., Kumar, S., Thyla, P.R., Sripriyan, K. (eds) Advances in Additive Manufacturing and Metal Joining. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-19-7612-4_31

Download citation

DOI: https://doi.org/10.1007/978-981-19-7612-4_31

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-19-7611-7

Online ISBN: 978-981-19-7612-4

eBook Packages: EngineeringEngineering (R0)