Abstract

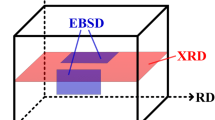

We present a detailed characterization of crystallographic texture and in-grain morphology in high purity Tantalum (Ta) during cross-rolling. A Ta disk with random initial texture was rolled to a total reduction of 50 pct in four equal steps, with the disk being rotated by 90 deg around the normal direction (ND) after every rolling step. Samples were cut along ND and were characterized using electron backscatter diffraction (EBSD), before and after the final deformation. Through-thickness texture heterogeneity was observed in the deformed disk, with an increase in 〈111〉 and 〈100〉 volume fraction parallel to ND from the surface toward the disk mid-section. The deformed texture of the mid-section of the disk (i.e., experiencing limited shear) was found to have a strong γ-fiber and a weak α-fiber with presence of only {100} 〈110〉 texture component. From the grain-scale EBSD study, the deformed grain morphology was found to be one of the three major types: (a) un-fragmented, (b) fragmented-mottled, and (c) fragmented-banded or elongated deformation bands. The un-fragmented grains had 〈111〉 parallel to ND, with 〈110〉 parallel to the rolling direction or the transverse direction. The fragmented-mottled grains had multiple sub-grain orientations. The two major bands in the fragmented-banded grains had its 〈100〉 and 〈111〉 parallel to ND. In addition, they shared a common 〈110〉 with a misorientation of 30 deg. Through our knowledge of the known stable components formed during rolling of Ta, it was feasible to explain the orientations of such un-fragmented and fragmented-banded grains.

Similar content being viewed by others

References

D. Raabe, K. Lucke, and G. Gottstein: J. De Physique IV, 1993, vol. 3, pp. 523-526.

D. Raabe, G. Schlenkert, H. Weisshaupt, and K. Lucke: Mat. Sci. Tech., 1994, vol. 10, pp. 299-305.

D. Raabe, B. Mulders, G. Gottstein, and K. Lucke: Mat. Sci. Forum, 1994, vol. 157-162, pp. 841-846.

K. H. Song, H. S. Kim, and W. Y. Kim: Mat. Sci. Forum, 2012, vol. 706-709, pp. 2652-2656.

C. Deng, S. F. Liu, J. L. Ji, X. B. Hao, Z. Q. Zhang, and Q. Liu: J. Mat. Proc. Tech., 2014, vol. 214, pp. 462-469.

Z. Zhang, D. Chen, H. Zhao, and S. Liu: Int. J. Ref. Met. Hard Mater., 2013, vol. 41, pp. 453-460.

J. B. Clark, R. K. Garrett, Jr., T. L. Jungling, R. A. Vandermeer, and C. L. Vold: Met. Trans. A, 1991, vol. 22A, pp. 2039-2048.

J. B. Clark, R. K. Garrett, T. L. Jungling, and R. I. Asfahani: Met. Trans. A, 1992, vol. 23A, pp. 2183-2191.

H. R. Z. Sandim, J. P. Martins, and A. F. Padilha: Scripta Mater., 2001, vol. 45, pp. 733-738.

H. R. Z. Sandim, J. P. Martins, A. L. Pinto, and A. F. Padilha: Mat. Sci. Engg. A, 2005, vol. 392, pp. 209-221.

H. Lim, J. D. Carroll, C. C. Battaile, T. E. Buchheit, B. L. Boyce, and C. R. Weinberger: Int. J. Plasticity, 2014, vol. 60, 1-18.

M. Kothari and L. Anand: J. Mech. Phys. Solids, 1998, vol. 46, pp. 51-83.

S. Nemat-Nasser, T. Okinaka, and L. Ni: J. Mech. Phys. Solids, 1998, vol. 46, pp. 1009-1038.

S. N. Kuchnicki, R. A. Radovitzky, and A. M. Cuitino: Int. J. Plasticity, 2008, vol. 24, pp. 2173-2191.

R. A. Lebensohn and C. N. Tome: Mat. Sci. Engg. A, 1994, vol. 175, pp. 71-82.

M. Knezevic, I. J. Beyerlein, M. L. Lovato, C. N. Tome, A. W. Richards, and R. J. McCabe: Int. J. Plasticity, 2014, vol. 62, pp. 93-104.

D.W. Richards, M.P. Kramer, J.W. House, and R.J. De Angelis: Int. C. Diff. Data, Advances in X-ray Analysis, 2003, vol. 46, pp. 285–90.

J. Tarasiuk, Ph. Gerber, B. Bacroix: Acta Mat., 2002, vol. 50, pp. 1467-1477.

P. Poelt, C. Sommitsch, S. Mitsche, and M. Walter: Mat. Sci. Engg. A, 2006, vol. 420, pp. 306-314.

D. Stojakovic: Proc. Appl. Ceramics, 2012, vol. 6, pp. 1-13.

B. J. Duggan, G. L. Liu, and L. X. Zhang: Mat. Sci. Forum, 1998, vol. 273-275, pp. 291-298.

Y. Y. Tse, G. L. Liu, and B. J. Duggan: Scripta Mater., 2000, vol. 42, pp. 25-30.

C. S. Lee and B. J. Duggan: Acta Metall. Mater., 1993, vol. 41, pp. 2691-2699.

A. Bhattacharyya, E. El-Danaf, S. R. Kalidindi, and R. D. Doherty: Int. J. Plasticity, 2001, vol. 17, pp. 861-883.

F. Besson and J. H. Driver: Acta Mater., 2000, vol. 48, pp. 2101-2115.

Q. Liu, J. Wert, and N. Hansen: Acta Mater., 2000, vol. 48, pp. 4267-4279.

C. S. Lee, B. J. Duggan, and R. E. Smallman: Acta Metall. Mater., 1993, vol. 41, pp. 2265-2270.

D. Kuhlmann-Wilsdorf: Acta Mater., 1999, vol. 47, pp. 1697-1712.

S. R. Kalidindi, A. Bhattacharya, and R.D. Doherty: Proc. R. Soc. London A, 2004, vol. 460, pp. 1935-1956.

F. J. Humphreys and M. Hatherly: Recrystallization and Related Annealing Phenomena, 2nd Ed., Elsevier Ltd., Oxford, UK, 2004.

Q. Liu, C. Maurice, J. Driver, and N. Hansen: Metall. Mater. Trans., 1998, vol. 29A, pp. 2333-2344.

C. Maurice, J. H. Driver: Acta mater., 1997, vol. 45, pp. 4627-4638.

H. R. Z. Sandim and D. Raabe: Scripta Mater., 2005, vol. 53, pp. 207-212.

S. Suwas, R.A. Massion, L.S. Tóth, J.-J. Fundenberger, and B. Beausir: Mater. Sci. Eng. A, 2009, vol. 520, pp. 134–46.

D.E. Laughlin and K. Hono: Physical Metallurgy, 5th ed., vol. 1, Elsevier Ltd., Oxford, U.K., 2014.

J. F. Butler Jr and H. Hu: Mat. Sci. Engg. A, 1989, vol. 114, pp. L29-L33.

R. Quey, P. R. Dawson, J. H. Driver: J. Mech. Phys. Solids, 2012, vol. 60, pp. 509-524.

Acknowledgments

Support for this research was provided by H.C. Starck, Newton, MA, 02461, USA.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted May 27, 2014.

Rights and permissions

About this article

Cite this article

Bhattacharyya, A., Knezevic, M. & Abouaf, M. Characterization of Crystallographic Texture and Intra-Grain Morphology in Cross-Rolled Tantalum. Metall Mater Trans A 46, 1085–1096 (2015). https://doi.org/10.1007/s11661-014-2686-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-014-2686-2