Abstract

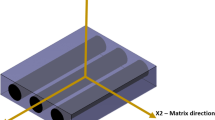

Thermal bonding is the fastest and the cheapest technique for manufacturing nonwovens. Understanding mechanical behaviour of these materials, especially related to damage, can aid in design of products containing nonwoven parts. A finite element (FE) model incorporating mechanical properties related to damage such as maximum stress and strain at failure of fabric’s fibres would be a powerful design and optimisation tool. In this study, polypropylene-based thermally bonded nonwovens manufactured at optimal processing conditions were used as a model system. A damage behaviour of the nonwoven fabric is governed by its single-fibre properties, which are obtained by conducting tensile tests over a wide range of strain rates. The fibres for the tests were extracted from the nonwoven fabric in a way that a single bond point was attached at both ends of each fibre. Additionally, similar tests were performed on unprocessed fibres, which form the nonwoven. Those experiments not only provided insight into damage mechanisms of fibres in thermally bonded nonwovens but also demonstrated a significant drop in magnitudes of failure stress and respective strain in fibres due to the bonding process. A novel technique was introduced in this study to develop damage criteria based on the deformation and fracture behaviour of a single fibre in a thermally bonded nonwoven fabric. The damage behaviour of a fibrous network within the thermally bonded fabric was simulated with a FE model consisting of a number of fibres attached to two neighbouring bond points. Additionally, various arrangements of fibres’ orientation and material properties were implemented in the model to analyse the respective effects.

Similar content being viewed by others

References

Russell SJ (2007) Handbook of nonwovens. Woodhead Publishing Limited, Cambridge

Albrecht W, Fuchs H, Kittelmann W (2003) Nonwoven fabrics: raw materials, manufacture, applications, characteristics, testing processes. Wiley-VCH, Weinheim

Chidambaram A, Davis H, Batra S (2000) Inter Nonwovens J 9:27

Wang X, Michielsen S (2001) Text Res J 71:475

Wang X, Stephen M (2002) Text Res J 702:394

Michielsen S, Pourdeyhimi B, Desai P (2006) J Appl Polym Sci 99:2489

Michielsen S, Wang X (2002) Int Nonwovens J 11:35

Dharmadhikary RK, Davis H, Gilmore TF, Batra SK (1999) Textile Res J 69:725

Hedge RR, Bhat GS, Campbell RA (2008) J Appl Polym Sci 110:3047

Bhat GS, Jangala PK, Spruiell JE (2004) J Appl Polym Sci 92:3593

Demirci E, Hou X, Acar M, Pourdeyhimi B, Silberschmidt VV (2012) Solid State Phenom 188:164

Demirci E, Acar M, Pourdeyhimi B, Silberschmidt VV (2012) Comput Mater Sci 52:157

Demirci E, Acar M, Pourdeyhimi B, Silberschmidt VV (2011) Appl Mech Mater 70:410

Demirci E, Acar M, Pourdeyhimi B, Silberschmidt VV (2011) Comput Mater Sci 50:1286

Demirci E, Acar M, Pourdeyhimi B, Silberschmidt VV (2010) ASME Conf Proc; ESDA2010, p 117

Sabuncuoglu B, Acar M, Silberschmidt VV (2012) Comput Mater Sci 52:164

Hou X, Acar M, Silberschmidt VV (2011) Comput Mater Sci 50:1292

Hou X, Acar M, Silberschmidt VV (2011) J Mater Sci 46:307. doi:10.1007/s10853-010-4800-1

Hou X, Acar M, Silberschmidt VV (2009) Comput Mater Sci 46:700

Farukh F, Demirci E, Sabuncuoglu B, Acar M, Pourdeyhimi B, Silberschmidt VV (2012) Comput Mater Sci 64:112. doi:10.1016/j.commatsci.2012.05.038

Rawal A, Priyadarshi A, Lomov SV, Verpoest IJ, Vankerrebrouck J (2010) J Mater Sci 45:2274. doi:10.1007/s10853-009-4152-x

Rawal A, Priyadarshi A, Kumar N (2010) J Mater Sci 45:6643. doi:10.1007/s10853-010-4755-2

Schulgasser K (1981) Fibre Sci Technol 15:257

Ostoja-Starzewski M, Stahl DC (2000) J Elast 60:131

Isaksson P, Hagglund R (2007) Int J Solids Struct 44:659

Isaksson P, Hagglund R, Gradin P (2004) Int J Solids Struct 41:4731

Farukh F, Demirci E, Acar M, Pourdeyhimi B, Silberschmidt VV (2012) J Phys Conf Ser 382:012018

Acknowledgements

We greatly acknowledge support by the Nonwovens Cooperative Research Centre of North Carolina State University, Raleigh, USA. FiberVisions®, USA generously provided the material for this study. We also acknowledge the use of Photron (Fastcam SA3), borrowed from the EPSRC UK Engineering Instrument Pool.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Farukh, F., Demirci, E., Acar, M. et al. Meso-scale deformation and damage in thermally bonded nonwovens. J Mater Sci 48, 2334–2345 (2013). https://doi.org/10.1007/s10853-012-7013-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7013-y