Abstract

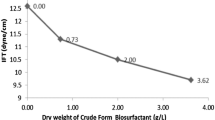

Production of biosurfactant by free and alginate-entrapped cells of Pseudomonas fluorescens Migula 1895-DSMZ was investigated using olive oil as the sole carbon and energy source. Biosurfactant synthesis was followed by measuring surface tension and emulsifying index E24 over 5 days at ambient temperature and at neutral pH. Diffusional limitations in alginate beads affected the kinetics of biosurfactant production when compared to that obtained with free cells culture. Nevertheless, the emulsion stability was improved and fewer by-products interfered with the biosurfactant activity. A decrease in pH down to 5 in the case of immobilized cells was observed during the first 3 days, after which it returned to its initial value. The minimum values of surface tension were 30 and 35 dynes cm−1 achieved after 40 and 72 h with free and immobilized cells, respectively, while the corresponding maximum E24 values were 67 and 62%, respectively. After separation by acetone precipitation, the biosurfactant showed a rhamnolipid-type in nature, and had a good foaming and emulsifying activities. The critical micellar concentration was found to be 290 mg l−1. The biosurfactant also showed good stability during exposure to high temperatures (up to 120 °C for 15 min), to high salinity (10% NaCl) and to a wide range of pH (4–9).

Similar content being viewed by others

References

Abouseoud M, Maachi R, Amrane A, Boudergua S, Nabi A (2008) Evaluation of different carbon and nitrogen sources in production of biosurfactant by Pseudomonas fluorescens. Desalination 223:143–151

Abu-Ruwaida AS, Banat IM, Haditirto S, Salem A, Kadri M (1991) Isolation of biosurfactant-producing bacteria product characterization, and evaluation. Acta Biotechnol 11:315–324

Banat IM (2000) Les biosurfactants, plus que jamais sollicités. Biofutur 198:44–47

Banat IM, Makkar RS, Cameotra SS (2000) Potential commercial applications of microbial surfactants. Appl Microbiol Biotechnol 53:495–508

Bonilla M, Olivaro C, Corona M, Vazquez A, Soubes M (2005) Production and characterization of a new bioemulsifier from Pseudomonas putida ML2. J Appl Microbiol 98:456–463

Cooper DG, Goldenberg BG (1987) Surface-active agents from two Bacillus species. Appl Environ Microbiol 53(2):224–229

Desai JD, Banat IM (1997) Microbial production of surfactants and their commercial potential. Microbiol Mol Biol Rev 61(3):47–64

Dubois M, Gills KA, Hamilton JK, Rebers PA, Smith F (1956) Colorimetric method for determination of sugar and related substances. Anal Chem 28:350–356

Haba E, Espuny MJ, Busquets M, Manresa A (2000) Screening and production of rhamnolipids by Pseudomonas aeroginusa 47T2 NCIB 40044 from waste frying oils. J Appl Microbiol 88:379–387

Hye-Sung J, Dong-Jung L, Sun-Hee H, Soon-Duck H, Jai-Yul K (2004) Rhamnolipid production by Pseudomonas aeruginosa immobilised in polyvinyl alcohol beads. Biotechnol Lett 26:35–39

Inoue S, Itoh S (1982) Sophorolipids from Torulopsis bombicola as microbial surfactants in alkane fermentation. Biotechnol Lett 4:3–8

Karsa DR, Bailey RM, Shelmerdine B, McCann SA (1999) Overview: a decade of change in the surfactant industry. In: Karsa DR (ed) Industrial applications of surfactants, vol 4. Royal Society of Chemistry, London, pp 1–22

Kim H, Yoon B, Lee C, Suh H, Oh H, Katsuragi T, Tani Y (1997) Production and properties of a lipopeptide biosurfactant from Bacillus subtilis C9. J Ferment Bioeng 84(1):41–46

Klein J, Wagner F (1987) Different strategies to optimize the production phase of immobilised cells. Ann N Y Acad Sci 501:306–316

Koch AK, Kappeli O, Fiechter A, Reiser J (1991) Hydrocarbon assimilation and biosurfactant production in Pseudomonas aeruginosa mutants. J Bacteriol 173:4212–4219

Mahanty B, Pakshirajan K, Dasu VV (2006) Production and properties of a biosurfactant applied to polycyclic aromatic hydrocarbon solubilization. Appl Biochem Biotechnol 134:129–141

Meylheuc T, Heary JM, Bellon-Fontaine MN (2001) Les biosurfactants, des biomolécules à forte potentialité d’application. Sci Aliments 21:591–649

Persson A, Österberg E, Dostalek M (1988) Biosurfactant production by Pseudomonas fluorescens 378: growth and product characteristics. Appl Microbiol Biotechnol 29(1):1–4

Pruthi V, Cameotra SS (1995) Rapid method for monitoring maximum biosurfactant production obtained by acetone precipitation. Biotechnol Lett 9(4):271–276

Santos AS, Sampaio AW, Vasquez GS, Santa Anna LM, Pereira N, Freire MG (2002) Evaluation of different carbon and nitrogen sources in production of rhamnolipids by a strain of Pseudomonas aeruginosa. Appl Biochem Biotechnol 98(100):1025–1035

Sarrubo LA, Luna JM, Campos-Takaki GM (2006) Production and stability studies of the bioemulsifier obtained from a new strain of Candida glabrata UCP 1002. Electronic J Biotechnol 9:400–406

Shin KH, Kim KW, Seagren EA (2004) Combined effects of pH and biosurfactant addition on solubilization and biodegradation of phenanthrene. Appl Microbiol Biotechnol 65:336–343

Siemann M, Wagner F (1993) Prospects and limits for the production of biosurfactants using immobilized biocatalysts. Surfactant Sci Ser 48:99–133

Vipulanandan C, Ren X (2000) Enhanced solubility and biodegradation of naphthalene with biosurfactant. J Environ Eng 7:629–634

Webb C, Black GM, Atkinson B (1986) Process engineering aspects of immobilized cell systems. Institution of Chemical Engineers, Oxford, 320 pp

Wilson NG, Bradley G (1996) The effect of immobilization on rhamnolipid production by Pseudomonas fluorescens. J Appl Bacteriol 81(5):525–530

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abouseoud, M., Yataghene, A., Amrane, A. et al. Biosurfactant production by free and alginate entrapped cells of Pseudomonas fluorescens . J Ind Microbiol Biotechnol 35, 1303–1308 (2008). https://doi.org/10.1007/s10295-008-0411-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10295-008-0411-0