Abstract

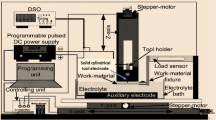

Electrical discharge hole drilling is a variation of electrical discharge machining (EDM) process, which has been widely used for making starting holes for wire-EDM applications, opening ventilating holes on dies and diesel ejectors and turbine blade cooling holes, etc. In this research work, an automated and intelligent system was developed for EDM hole drilling operations on aerospace alloys, namely Inconel 718 (IN718) and Ti-6Al-4V (Ti64). The developed system can be used to design EDM drilling process such as choosing optimal and/or best drilling parameters (discharge current, pulse-on time, pulse-off time, and capacitance rate). In accordance with this, the EDM process outcomes such as total drilling time, minimum required electrode length, and roughness of the produced surface can also be obtained as system outputs. The input–output interactions have also been achieved via adaptive neuro-fuzzy inference technique that allows designing the drilling operations in an efficient, effective, and reliable way. The developed system has an interactive and visual interface for ease of use.

Similar content being viewed by others

References

Sommer C, Sommer S (2005) Complete EDM Handbook. www.reliableedm.com/Complete-EDM-Handbook.html. Accessed 02 August 2013

Leao FN, Pashby IR, Cuttell M, Lord P (2005) Optimization of EDM fast hole-drilling through evaluation of dielectric and electrode materials. Proc. of 18thIntCongrMechEng (COBEM), OuroPreto, Brasil

Kuppan P, Rajadurai A, Narayanan S (2008) Influence of EDM process parameters in deep hole drilling of Inconel 718. Int J Adv Manuf Technol 38(1–2):74–84

Jeswani ML (1979) Small hole drilling in EDM. Int J Mach Tools Des Res 19:165–169

Wang CC, Yan BH (2000) Blind-hole drilling of Al2O3/6061 Al composite using rotary electro-discharge machining. J Mater Process Technol 102:90–102

Mohan B, Rajadurai A, Satyanarayana KG (2002) Effect of SiC and rotation of electrode on electrical discharge machining of Al-SiC composite. J Mater Process Technol 124:297–304

Asokan T, Reddy SS, Costa PDE (2000) Electrical discharge drilling of titanium alloys for aerospace applications. Proc of 19th AIMTDR Conf, IIT Madras, Chennai, 161–165

Soni JS, Chakraverti G (1993) Surface characteristics of titanium with rotary EDM. Bull Mater Sci 16(3):213–227

Mohan S, Shan HS (2007) Electrojet drilling using hybrid NNGA approach. Robot Comput Integr Manuf 23:17–24

Liu TI, Kumagai A, Wang YC, Song SD, Fu Z, Lee J (2010) On-line monitoring of boring tools for control of boring operations. Robot Comp Integ Manuf 26:230–239

ZuperlU CF, Reibenschuh M (2011) Neural control strategy of constant cutting force system in end milling. Robot Comput Integr Manuf 27:485–493

Montgomery DC (2001) Design and analysis of experiments handbook. Willey & Sons Inc.

Okka MA (2011) An experimental investigation of electrical discharge machining (EDM) fast hole drilling of Inconel 718 & Ti-6Al-4V. MSc Dissertation, University of Gaziantep, Turkey

Buragohain M, Mahanta C (2008) A novel approach for ANFIS modeling based on full factorial design. Appl Soft Comput 8:609–625

Ying LC, Pan MC (2008) Using adaptive network based fuzzy inference system to forecast regional electricity loads. Energy Convers Manag 49:205–211

Alan F (2011) Development of neuro-fuzzy models for hole drilling on Ti-6Al-4V and Inconel 718 using electrical discharge machining. MSc Dissertation, University of Gaziantep, Turkey

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yilmaz, O., Bozdana, A.T. & Okka, M.A. An intelligent and automated system for electrical discharge drilling of aerospace alloys: Inconel 718 and Ti-6Al-4V. Int J Adv Manuf Technol 74, 1323–1336 (2014). https://doi.org/10.1007/s00170-014-6059-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-014-6059-1