Abstract

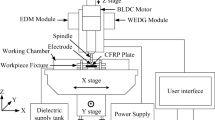

Drilling micro holes on various engineering materials have been performed using electrochemical discharge machining (ECDM), especially non-conductive material. A predefined and controlled work material feeding is essential and plays a crucial role during drilling. Thus various feeding approaches have been developed and investigated for the ECDM process. The adaptive tool feeding system in the ECDM process has specific features to fulfill all the relevant requirements for the ECDM process. This system is rarely found in the published literature due to its complexity in design and operation. Therefore, the present research explains the process mechanism of an adaptive tool-feeding system for ECDM. Extensive experiments are performed to investigate the effect of the working gap, tool feed, and dwell time on machined hole depth and hole entrance diameter. A clear process mechanism is presented for all theinput process parameters during the machining process. Besides, multi-criteria optimization is performed to obtain the optimum values of process parameters.

Similar content being viewed by others

References

Singh, T., Appalanaidu, B., Dvivedi, A.: Improvement in energy channelization behaviour during micro hole formation in Y-SZ ceramic with magnetic field assisted ECSM process. Measurement 194, 111079 (2022)

Elhami, S., Razfar, M.R.: Numerical and experimental study of discharge mechanism in the electrochemical discharge machining process. J. Manuf. Process. 50, 192–203 (2020)

Abou Ziki, J.D., Wüthrich, R.: Forces exerted on the tool-electrode during constant-feed glass micro-drilling by spark assisted chemical engraving. Int. J. Mach. Tools Manuf 73, 47–54 (2013)

Appalanaidu, B., Dvivedi, A.: On the use of sacrificial layer in ECDM process for form accuracy. J. Manuf. Process. 79, 219–232 (2022)

Kannojia, H.K., Arab, J., Sidhique, A., Mishra, D.K., Kumar, R., Pednekar, J. and Dixit, P.: Fabrication and characterization of through-glass vias (TGV) based 3D spiral and toroidal inductors by cost-effective ECDM process. In 2020 IEEE 70th Electronic Components and Technology Conference (ECTC) (pp. 1192–1198). IEEE

Arya, R.K., Dvivedi, A.: Thermal loading effect during machining of borosilicate glass using ECDM process. IOP Conf. Ser. Mater. Sci. Eng.. 647(1), 012001 (2019)

Jalali, M., Maillard, P., Wüthrich, R.: Toward a better understanding of glass gravity-feed micro-hole drilling with electrochemical discharges. J. Micromech. Microeng. 19(4), 045001 (2009)

Saranya, S., Sankar, A.R.: Fabrication of precise micro-holes on quartz substrates with improved aspect ratio using a constant velocity-feed drilling technique of an ECDM process. J. Micromech. Microeng. 28(12), 125009 (2018)

Appalanaidu, B., Dvivedi, A.: On controlling of gas film shape in electrochemical discharge machining process for fabrication of elliptical holes. Mater. Manuf. Process. 36(5), 558–571 (2021)

Mehrabi, F., Farahnakian, M., Elhami, S., Razfar, M.R.: Application of electrolyte injection to the electro-chemical discharge machining (ECDM) on the optical glass. J. Mater. Process. Technol. 255, 665–672 (2018)

Arya, R.K., Dvivedi, A.: Investigations on quantification and replenishment of vaporized electrolyte during deep micro-holes drilling using pressurized flow-ECDM process. J. Mater. Process. Technol. 266, 217–229 (2019)

Arya, R.K., Paliwal, S., Dvivedi, A., Maran, R.: Investigation on deposition of the machined by-products and its reduction during electrochemical discharge machining (ECDM). J. Electrochem. Soc. 169(2), 023506 (2022)

Kumar, S., Dvivedi, A.: On machining of hard and brittle materials using rotary tool micro-ultrasonic drilling process. Mater. Manuf. Processes 34(7), 736–748 (2019)

Arab, J., Mishra, D.K., Kannojia, H.K., Adhale, P., Dixit, P.: Fabrication of multiple through-holes in non-conductive materials by electrochemical discharge machining for RF MEMS packaging. J. Mater. Process. Technol. 271, 542–553 (2019)

Arab, J., Kannojia, H.K., Dixit, P.: Effect of tool electrode roughness on the geometric characteristics of through-holes formed by ECDM. Precis. Eng. 60, 437–447 (2019)

Arab, J., Dixit, P.: Influence of tool electrode feed rate in the electrochemical discharge drilling of a glass substrate. Mater. Manuf. Process. 35(15), 1749–1760 (2020)

Wüthrich, R., Fascio, V.: Machining of non-conducting materials using electrochemical discharge phenomenon—an overview. Int. J. Mach. Tools Manuf. 45(9), 1095–1108 (2005)

Hof, L.A., Abou Ziki, J.: Micro-hole drilling on glass substrates—a review. Micromachines 8(2), 53 (2017)

Gupta, P.K., Dvivedi, A., Kumar, P.: A study on the phenomenon of hole overcut with working gap in ECDM. J. Product. Eng. 17, 30–34 (2014)

Singh, T., Arya, R.K., Dvivedi, A.: Experimental investigations into rotary mode electrochemical discharge drilling (RM-ECDD) of metal matrix composites. Mach. Sci. Technol. 24(2), 195–226 (2020)

Bindu, M.J., Somashekhar, S.H.: Machining of microholes on borosilicate glass using micro-electro chemical discharge machining (µ-ECDM) and parametric optimisation. Adv. Mat. Proc. Tech. 5, 542–557 (2019)

Derringer, G., Suich, R.: Simultaneous optimization of several response variables. J. Qual. Technol. 12(4), 214–219 (1980)

Kumar, S., Dvivedi, A.: Micro-ultrasonic drilling of monocrystalline silicon: an experimental investigation on machined surface topography and optimization using User’s preference rating based TOPSIS. Mater. Sci. Semicond. Process. 102, 104584 (2019)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arya, R.K., Appalanaidu, B. & Dvivedi, A. Parametric investigation on an adaptive tool feeding system for ECDM. Int J Interact Des Manuf (2023). https://doi.org/10.1007/s12008-023-01227-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-023-01227-6