Abstract

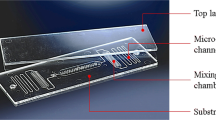

The use of laser welding for joining micro parts has experienced a substantial increase in popularity during recent years. Specifically translucent microfluidic devices are assembled using laser welding; however, a major issue is the laser beam size of commercially available laser-welding equipment and thus the resulting welding seam size, which may be orders of magnitude larger than microfluidic channels and structures. We have successfully achieved extremely small welding seams using focussed low-power laser diodes. Commercial laser welding stations for polymer assembly will typically operate in the power-region 15–50 Watts. The focussed laser beam will have a size of typically 500 μm × 500 μm and may, depending on optical configuration, be up to several mm2. The resulting welding-seam will thus be in the area of 300–600 μm depending on beam energy distribution; additionally the melt will spread to unheated areas due to capillary forces. As microfluidic channels are in 20–100 μm regions, even a very limited amount of stray melt may completely fill a part of a channel and thus render it useless. We have used commercially available “single-die” laser-diodes of optical power 200–500 mW. The beam has been focussed and directed using simple optical installations, resulting in a beam-size in the area of 50 μm × 5 μm full width half maximum (FWHM) We have achieved firm welding seams of width <10 μm, with a welding speed of 15 mm/s and with virtually no noticeable spread of melt.

Similar content being viewed by others

References

FLS Iron Scan, Fisba Optik AG, Rorschacher Strasse 268, 9016 St. Gallen, Switzerland. http://www.fisba.ch/

Ussing T (2002) Micro liquid handling device and methods for using it. Abstract of corresponding document: WO2004016948

ARM-core microcontroller, Atmel Corp., San Jose, CA http://www.atmel.com/products/AT91

PETG-CoPolyester, Eastar Chemicals, Sacramento, CA, US http://www.eastman.com/Brands/Eastar/Eastar_intro.asp

Topas® COC, Ticona, Oberhausen, Germany http://www.ticona.com/index/products/coc/Topas.htm

PRO-JET 830NP, Avecia, UK http://www.avecia.com/infrared/products/830np.htm

Zygo Corp., Middlefield,CT, US http://www.zygo.com/?/products/metrology.htm

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ussing, T., Petersen, L.V., Nielsen, C.B. et al. Micro laser welding of polymer microstructures using low power laser diodes. Int J Adv Manuf Technol 33, 198–205 (2007). https://doi.org/10.1007/s00170-007-0969-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-007-0969-0