Abstract

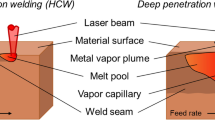

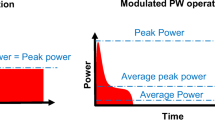

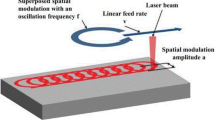

Joining of copper material in order to create a contact is an important task in electronics industry. Conventionally pulsed rod-based IR laser sources with low beam quality have a high energy input for welding copper due to large spot diameters. Fiber laser sources have high beam quality which allows small laser spots to be generated. Therefore, the threshold for deep penetration welding can be reached by using lower power. But when such small laser spots are used, the resulting connection area has to be enlarged. To achieve this, spatial power modulation has been introduced. The use of spatial power modulation—a linear feed with superposed circular motion—allows a significant expansion of process boundaries. The additional parameters of oscillation frequency and amplitude enable new strategies to control the laser welding process. This paper presents recent developments concerning process improvements and increase in efficiency by applying spatial power modulation. We discuss process regimes for spatial power modulation by analyzing the melt pool dynamic via high-speed videography. These regimes are an important aspect for process efficiency. Effects of heat conduction and spatial power modulation have been studied.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

Abbreviations

- As:

-

Oscillation amplitude [mm]

- f:

-

Focal length [mm]

- fs:

-

Oscillation frequency [Hz]

- P:

-

Laser power [W]

- t:

-

Time [ms]

- U:

-

Degree of overlap [–]

- vf:

-

Feed rate [mm/s]

- Ф:

-

Total oscillation angle [°]

- φ:

-

Periodical oscillation angle [°]

References

Martukanitz R, Stol I, Tressler JF, Warren CJ (2005) Development of the laser stir welding process for aluminum laser beam welding. In: ICALEO 2005: Congress proceedings 2005, Miami, Florida, October 31-November 3. Laser Institute of America, Orlando, FL, pp 712–718 (LIA pub; #598, vol 98)

Boglea A, Bosse L, Olowinsky A, Bou S (2006) Fiber laser pick-and-join tool for welding of thermoplastics. In: ICALEO 2006: Congress proceedings 2006, Scottsdale, AZ, USA, October 30–November 2. Laser Institute of America, pp 383–388 (LIA pub; #599, vol 99)

Gedicke J, Olowinsky A, Artal J, Gillner A (2007) Influence of temporal and spatial laser power modulation on melt pool dynamics. In: 26th International congress on applications of lasers and electro-optics: ICALEO 2007, October 29 -November 1, 2007, Orlando, Florida, USA. Laser Institute of America, Orlando, FL, pp 816–822

Gedicke J, Olowinsky A, Mehlmann B (2010) Laser beam welding of DCB substrates. In: 11th international symposium on laser precision microfabrication (LPM), June 7–10, 2010 in Stuttgart, Germany

Schmitt F, Mehlmann B, Gedicke J, Olowinsky A, Gillner A, Poprawe R (2010) Laser beam micro welding with high brilliant fiber lasers. J Laser Micro/Nanoeng 5(3):197–203

Schmitt F (2012) Laserstrahl-Mikroschweißen mit Strahlquellen hoher Brillanz und örtlicher Leistungsmodulation [Dissertation]. Aachen

Deutsches Kupferinstitut (2005) DKI—Werkstoffkennblätter

Chang C (2000) Berechnung der Schmelzbadgeometrie beim Laserstrahlschweißen mit Mehrfokustechnik: Herbert Utz Verlag München

Acknowledgements

All presented investigations were conducted in the context of the Collaborative Research Centre SFB 1120 project A1 and were funded by Deutsche Forschungsgemeinschaft e. V. (German Research Foundation).

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2022 Springer Nature Switzerland AG

About this paper

Cite this paper

Haeusler, A., Mehlmann, B., Olowinsky, A., Gillner, A., Poprawe, R. (2022). Efficient Copper Micro Welding with Fiber Lasers Using Spatial Power Modulation. In: Hinduja, S., da Silva Bartolo, P.J., Li, L., Jywe, WY. (eds) Proceedings of the 38th International MATADOR Conference. MATADOR 2015. Springer, Cham. https://doi.org/10.1007/978-3-319-64943-6_15

Download citation

DOI: https://doi.org/10.1007/978-3-319-64943-6_15

Published:

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-64942-9

Online ISBN: 978-3-319-64943-6

eBook Packages: EngineeringEngineering (R0)